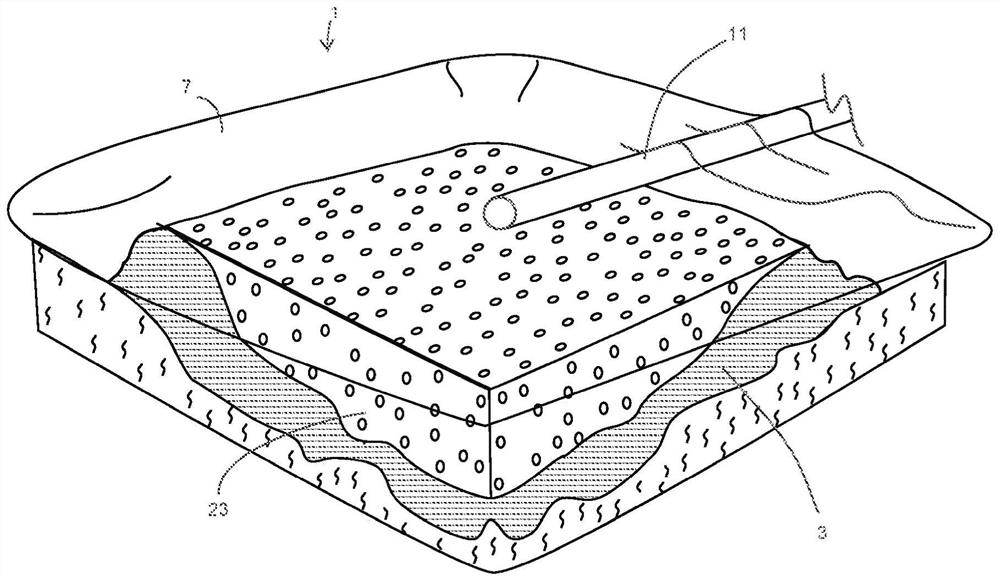

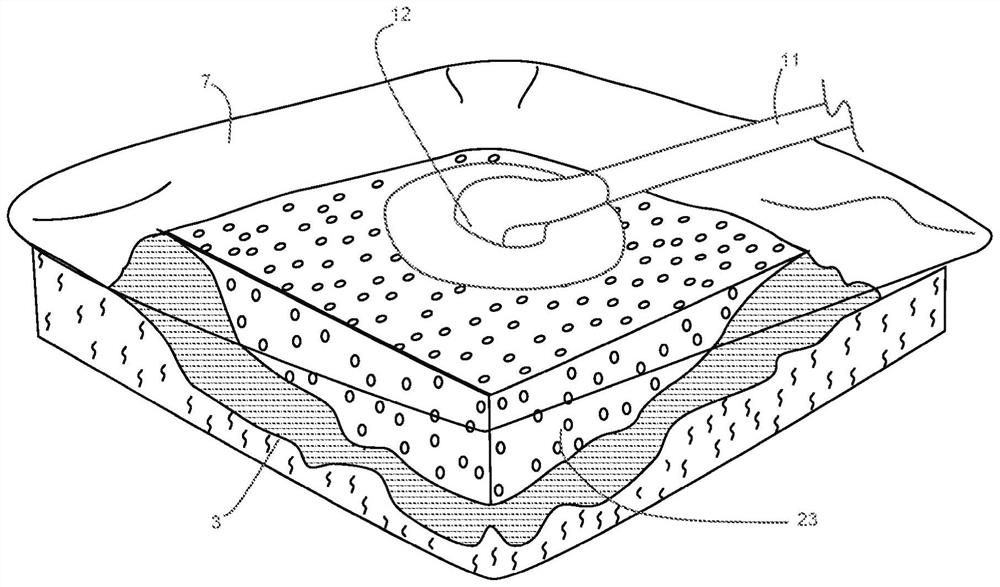

Negative pressure wound dressing piece

A technology for wounds and materials, applied in dressings, adhesive dressings, non-adhesive dressings, etc., can solve problems such as ineffective NPWT treatment and obstacles to negative pressure transmission at the wound interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0198] Example 1: Manufacturing method

[0199] The bioabsorbable layer 105 with x-shaped pores 119 was prepared according to the following method. refer to Figure 39-41 , a sheet of reticulated structure was prepared according to the method described in PCT application PCT / NZ2009 / 000152 to provide material 95 for processing using punching / perforating equipment 89 .

[0200] The blanking device 89 includes an upper press assembly including a punch retaining plate 92 , a punch needle assembly 99 and a clamping plate 90 . Punch assembly 99 includes a punch 93 and a punch holder 91 that is shaped to produce the desired final bore.

[0201] In this example, the punch 93 is shaped to produce Figure 16 The x-shaped aperture 119 is shown in (i) and has a width and height of approximately 5.5 millimeters with a slot thickness or width of approximately 0.5 millimeters.

[0202] The blanking apparatus 89 includes a press plate 94 aligned to translate along the same axis as the upp...

example 2

[0206] Example 2: Measuring pressure drop across various bioabsorbable layers

[0207] The following examples outline the equipment and test methods used to evaluate and compare the pressure drop of various materials and different forms of bioabsorbable layers. refer to Figure 42 , a pressure drop test apparatus 79 is constructed, which includes a base plate 81 , a base support 80 and a clamping ring 86 . The clamping ring 86 includes circumferential grooves ( Figure 42 not shown) to accommodate a rubber O-ring or other form of seal 85.

[0208] Base plate 81 includes two ports 82, each connected to a separate pressure sensor. Each pressure sensor is capable of accurately measuring vacuum pressure in the range of 0–400mmHg. The pressure sensors are referred to herein as measurement points P2 and P3. The two ports 82 are spaced approximately 45 millimeters apart. Base plate 81 may also include three spare ports 83 spaced about 45 millimeters from central pressure measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com