Epoxy gold terrazzo floor base layer leveling structure

A kind of epoxy gold, base layer technology, applied in the direction of building structure, floor, construction, etc., can solve the problems of improvement, high construction cost, unable to achieve standardized construction, etc., to achieve simple leveling process and improve construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

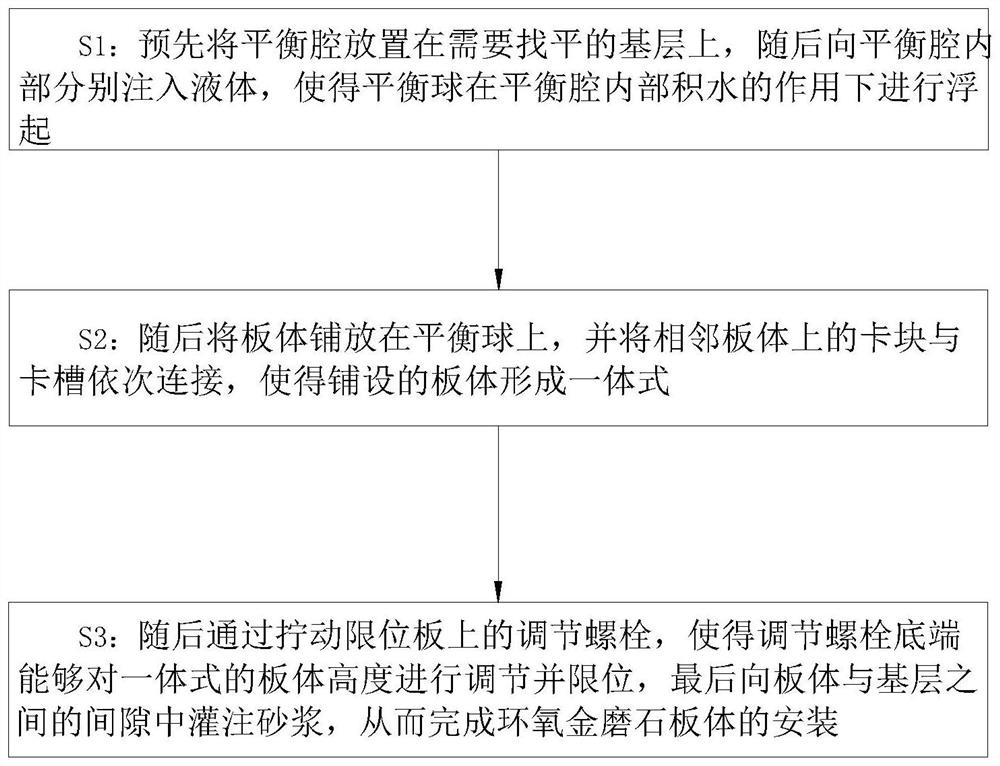

Embodiment approach

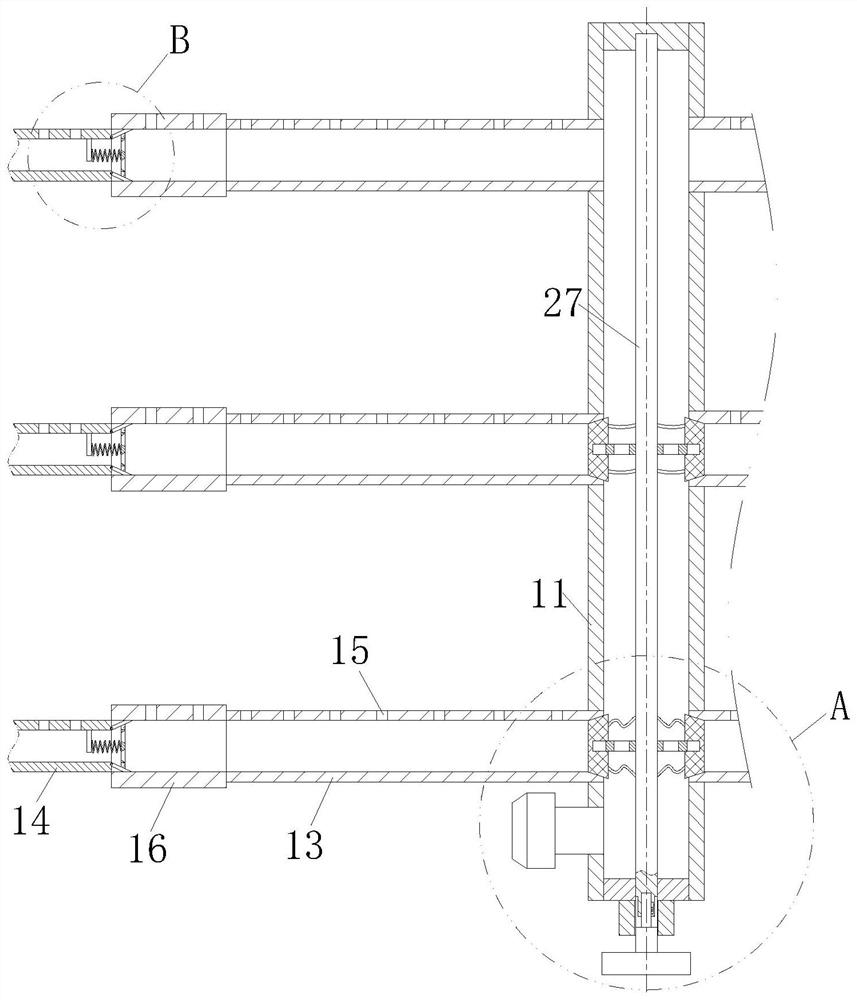

[0032] As an embodiment of the present invention, the cross-sectional shapes of the shunt pipe 13 and the communication pipe 14 are respectively back-shaped, and the ends of the shunt pipe 13 and the communication pipe 14 are respectively connected with a communication cavity 16. 14 and the inner wall of one end of the communicating cavity 16 are respectively connected with a blocking plate 17 through torsion spring rotation, and when the connecting tube 14 is aligned with the end of the communicating cavity 16, the blocking plate 17 can extend into the to the inside of the corresponding communication chamber 16; during work, when the two adjacent plates 7 are connected, the blocking plate 17 at the end of the communication pipe 14 can effectively extend into the interior of the communication chamber 16, and then in the process of pouring mortar In this process, the flowing mortar can exert pressure on the inclined blocking plate 17, so that the free end of the blocking plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com