Composite cleaning agent, preparation method thereof and method for treating evaporator scaling

A composite cleaning agent and evaporator technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, preparation of detergent mixture compositions, etc. Long-term stable operation, etc., to avoid corrosion, good cleaning effect, and excellent cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Composite cleaning agent configuration: First configure 11% ethanol solution, then add 7% of the industrial pure Tween -20 in the case of continuous stirring, after the temperature is completely dissolved, add 12% EDTA, then add 11% of the sodium hexaalkylsulfonate, and then adjusted pH to 9.

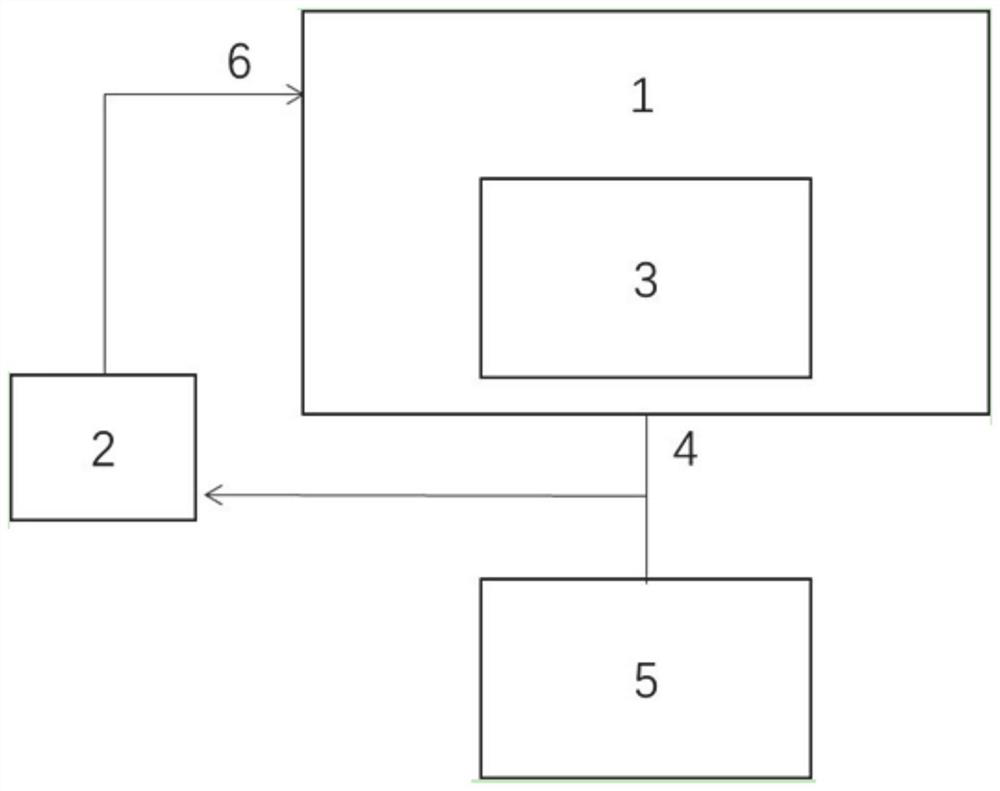

[0043] (2) Evaporator circulation step cleaning: figure 1 As shown, the composite cleaning agent is first diluted 5 times, and 1 / 10 is added to the evaporator 1 according to the 1 / 10 of the evaporator 1 unit time, and the liquid discharged through the discharge port 4, passed through the evaporator circulation pump 2, through the evaporator 1 The inlet 6 is entered into the evaporator 1, and the cycle time is controlled to 1.5 h, and the recirculation pump 2 is stopped, and the cleaning liquid is discharged into the centrifuge 5 through the discharge port 4, and then the dilute 10 times the cleaning agent, add The volume is 1 / 10 of the evaporator treatment volume, and then opens ...

Embodiment 2

[0049] (1) Composite cleaning agent configuration: in Example 1

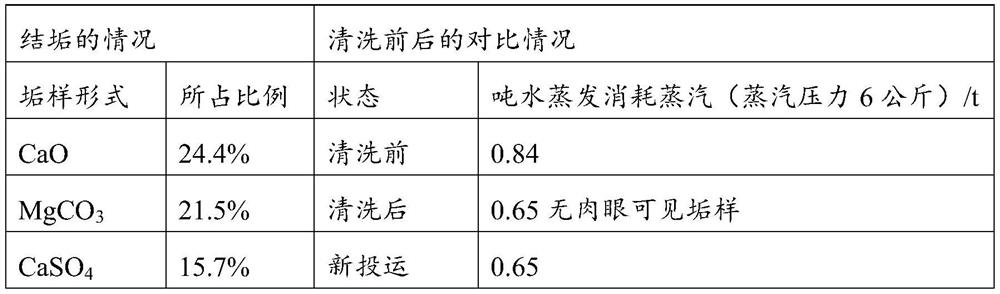

[0050] (2) Evaporator circulation step cleaning: step cleaning process is the same as in Example 1, the evaporator is a double-effect evaporator, and the average composition of the evaporator is shown in Table 2.

[0051] (3) Evaporator softening water rinsing: in Example 1

[0052] (4) Cleaning effect evaluation: Direct observation inside the evaporator, observing whether there is a visible scale of the naked eye, and after passing through the steam, investigate the relationship between the total heat transfer amount of steam and the amount of evapulmation wastewater in the unit time. The detection and heat transfer are shown in Table 2.

[0053] Table 2 detection and heat transfer

[0054]

Embodiment 3

[0056] (1) Composite cleaning agent configuration: in Example 1

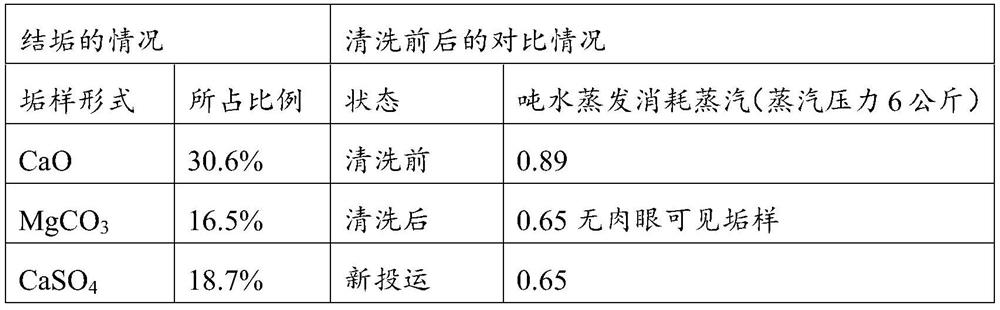

[0057] (2) Evaporator circulation step cleaning: step cleaning process is the same as in Example 1, the evaporator is a double-effect evaporator, and the average composition of the evaporator is shown in Table 3.

[0058] (3) Evaporator softening water rinsing: in Example 1

[0059] (4) Cleaning effect evaluation: Direct observation inside the evaporator, observing whether there is a visible scale of the naked eye, and after passing through the steam, investigate the relationship between the total heat transfer amount of steam and the amount of evapulmation wastewater in the unit time. The detection and heat transfer are shown in Table 3.

[0060] Table 3 detection and heat transfer

[0061]

[0062] Through Example 1- Embodiment 3, the composite cleaning agent according to the present invention can be used for the treatment of evaporator fouling of different components, and the heat transfer effect of the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com