Concrete base interface agent for preventing plastering gypsum mortar layer from bubbling and preparation method of concrete base interface agent

A technology of concrete base and plastering gypsum, applied in the direction of coating, etc., can solve the problems of interface agent construction performance decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

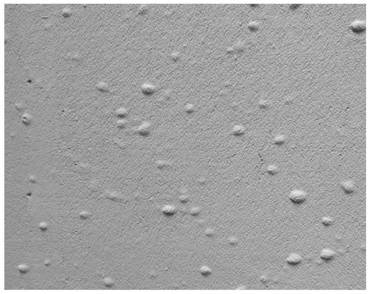

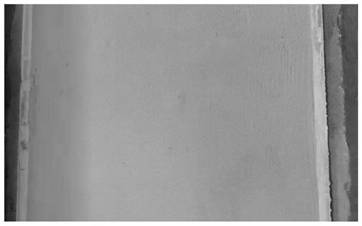

Image

Examples

preparation example Construction

[0085] The present invention also provides a kind of preparation method of the concrete base interface agent that prevents plastering gypsum mortar layer from foaming, comprising the following steps:

[0086] A) stirring and mixing the polymer emulsion, the protective colloid solution, the nano anti-alkali back cover emulsion and deionized water to obtain the mixed solution A;

[0087] B) under stirring conditions, add film-forming aids, antiseptics, freeze-thaw stabilizers, wetting agents, defoamers, dispersants and colorants to mixed solution A to obtain mixed solution B;

[0088] C) Adding a thickener and a pH regulator into the mixed solution B under stirring conditions to obtain a concrete base layer interface agent for preventing foaming of the plastered gypsum mortar layer.

[0089] In the present invention, the protective colloid is preferably dissolved in deionized water to prepare a protective colloid solution, and then the protective colloid solution is used for sub...

Embodiment 1

[0098] A base-layer interface agent for preventing foaming of the plastered gypsum mortar layer and includes the following components calculated by weight: 20 parts of vinyl acetate-ethylene copolymer emulsion, 10 parts of nano-bottom seal emulsion, 2 parts of PVA1788 polyvinyl alcohol, antiseptic and bactericide 0.5 parts, 0.6 parts of film-forming aid, 0.8 parts of thickener ASE-60, 0.3 parts of PH regulator, 0.8 parts of associative polyurethane thickener HY-304D, 0.3 parts of dispersant, 0.5 parts of freeze-thaw stabilizer, 0.2 parts of wetting agent, 0.5 parts of defoamer, 0.3 parts of colorant, 63.2 parts of deionized water.

[0099] The above-mentioned preparation method of the base-layer interface agent capable of preventing foaming of the plastered gypsum mortar layer comprises the following steps:

[0100] (1) First, 2 parts of polyvinyl alcohol 1788 were dissolved in 38 parts of deionized water to prepare a polyvinyl alcohol solution with a mass fraction of 5%.

[...

Embodiment 2

[0105] A base-layer interface agent for preventing foaming of a plastered gypsum mortar layer and includes the following components calculated by weight: 15 parts of elastic acrylate emulsion, 15 parts of nano-bottom cover emulsion, 2 parts of PVA2088 polyvinyl alcohol, 0.5 part of antiseptic and bactericide , 0.6 parts of film-forming aid, 0.4 parts of alkali-swellable associative thickener HY-303, 0.2 parts of pH regulator, 0.2 parts of hydroxyethyl cellulose, 0.3 parts of dispersant, 0.5 parts of freeze-thaw stabilizer, moistening 0.2 parts of wet agent, 0.5 parts of defoamer, 0.3 parts of coloring agent, 64.3 parts of deionized water.

[0106] The above-mentioned preparation method of the base-layer interface agent capable of preventing foaming of the plastered gypsum mortar layer comprises the following steps:

[0107] (1) First, 2 parts of polyvinyl alcohol 2088 were dissolved in 38 parts of deionized water to prepare a polyvinyl alcohol solution with a mass fraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com