Rigid-flexible coupling skin structure of shear type variable sweepback wing

A technology of rigid-flexible coupling and variable backsweep, which is applied in the aviation field to achieve the effects of improving flight efficiency, reducing energy consumption, and continuous splicing positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

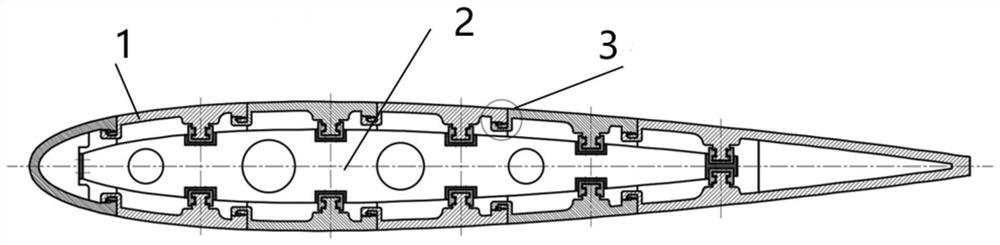

[0035] Specific implementation mode one: refer to figure 1 This embodiment is described in detail. The rigid-flexible coupling skin structure of a shear-type variable-sweep wing described in this embodiment includes a panel-type skin panel, load-bearing stringers and a sealing mechanism. The integral panel-type The skin panels are several independent units arranged in parallel, and the root of each skin panel sub-panel is connected to the fuselage through the bearing stringer lugs. The sealing structure is evenly distributed between each independent panel, and the sealing structured as Figure 7 As shown, the load-bearing stringers are glued with the integral wall panel skin surface and slide along the concave track on the support frame.

[0036] The wall panel type skin surface comprises a high temperature titanium alloy material, a rigid frame and a hexagonal honeycomb flexible structure. Alloy boundaries are joined by screws to form a siding-style skin patch. Each wall-t...

Embodiment

[0041] Such as figure 1 As shown, a rigid-flexible coupled skin structure of a shear-type variable-sweep wing includes a wall-type skin surface 1, a load-bearing stringer 2 and a sealing mechanism 3, and the integral wall-type skin surface 1 is several Independent units arranged in parallel, the root of each skin surface sub-surface is connected to the fuselage 5 through the bearing stringer lug 4, the sealing structure 3 is evenly distributed between each independent surface, and the bearing stringer The strip 2 is glued with the integral wall panel type skin surface 1 and slides along the concave track 6 on the support frame 8 .

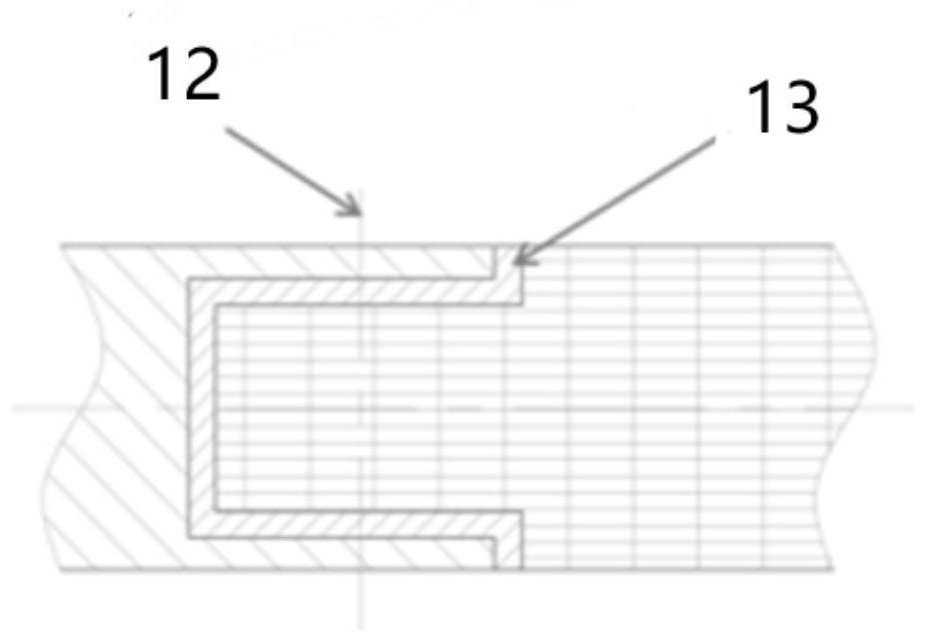

[0042] Such as image 3 As shown, the skin is in the form of a wall panel skin 1, and the material is high-temperature titanium alloy, which has the characteristics of large internal space and strong bearing capacity. The hexagonal honeycomb flexible material 12 adopts a metal frame dimension 13 at the edge, and the frame 13 and After the flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com