Vehicle door structure without B column

A technology for B-pillars and car doors, applied to doors, vehicle parts, bumpers, etc., can solve the problems of front door intrusion into the car, poor side impact safety performance, etc., and achieve the effect of ensuring life safety and improving the performance of absorbing side impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

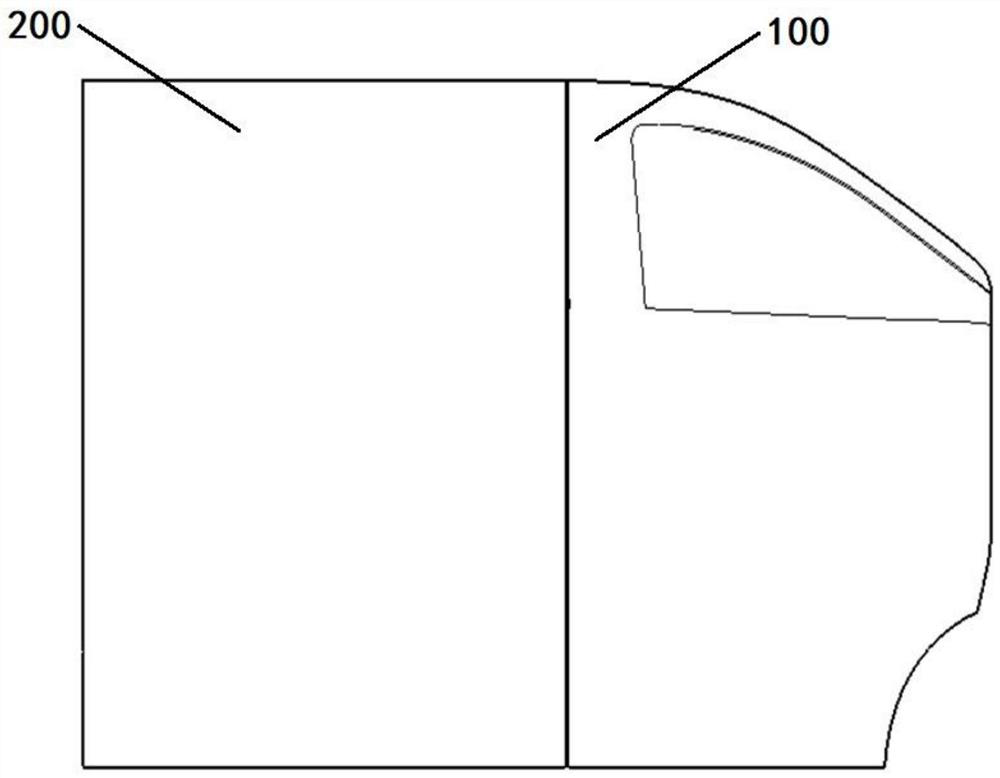

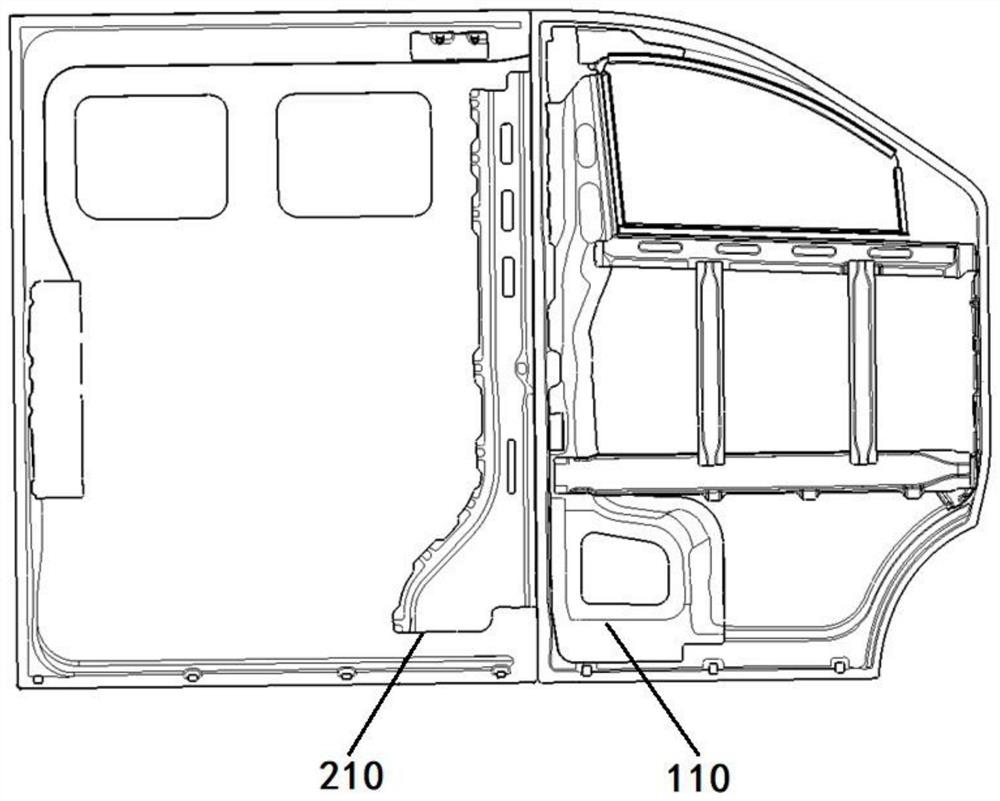

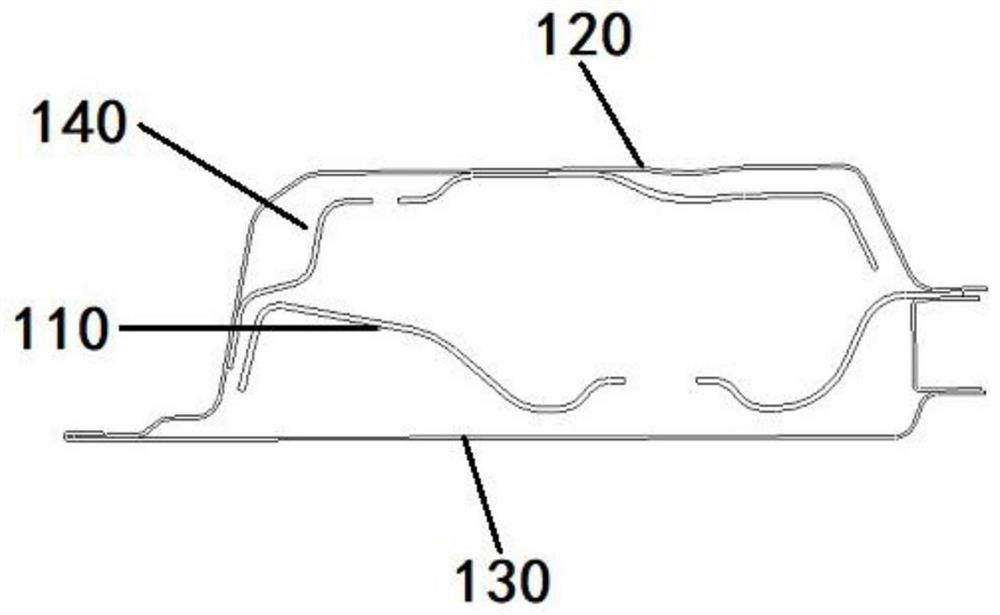

[0034] like Figure 1-2 As shown, the vehicle door structure without a B-pillar in this embodiment includes a sliding door 200 and a front door 100 that can be opened simultaneously. combine Figure 13 As shown, the front door 100 is welded by the front door inner panel 120 and the front door outer panel 130, the sliding door 200 is welded by the sliding door inner panel 210 and the sliding door outer panel 220, and the upper part of the front door 100 is provided with window frame. A front door B-pillar 110 is disposed inside the side of the front door 100 close to the sliding door 200 , and a sliding door B-pillar 210 is disposed inside the side of the sliding door 200 close to the front door 100 .

[0035] like figure 2 , 5 As shown in -8, a window frame reinforcing plate 140 is provided on the side of the inner window frame of the front door 100 close to the sliding door 200, and a locking reinforcing plate 160 is provided on the upper part of the window frame reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com