A farmland mulch film recycling operation machine and its use method

A technology for working machines and mulching films, which is applied in the directions of cleaning methods using liquids, recycling technologies, and cleaning methods using tools, etc., can solve the problems of inconvenient mulching films, ineffective separation of impurities such as mulching films and soil, and high impurity content in mulching films. for easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

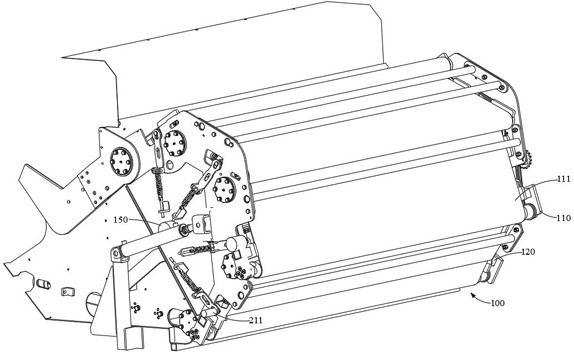

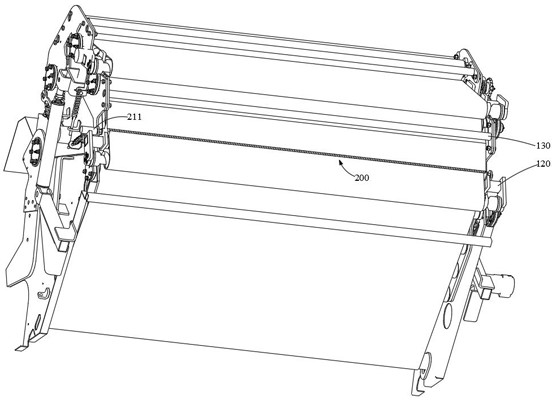

[0040] Such as Figure 1~5 As shown, a farmland mulching film recycling operation machine includes a conveying part 100, and the conveying part 100 includes a frame 110, a conveyor belt 111 that is rotatably arranged on the frame 110 and is fixedly arranged on the frame 110. extrusion rod 120;

[0041] The cleaning part 200, the cleaning part 200 includes a scraper 210 rotatably arranged on the frame 110, a first scraper 220 and a second scraper 230 respectively arranged at both ends of the scraper 210, a scraper 230 arranged on the scraper The connection plate 212 on both sides of the 210, the tension roller 213 fixed on the connection plate 212 and the grinding roller 130 arranged on the conveyor belt 111, one end of the tension roller 213 is provided with a cutting edge 215, and the scraper A plate 210 is located above the conveyor belt 111, and,

[0042] The connecting plate 212 is provided with an air bag 214, and the first scraper 220 is provided with a water outlet 22...

Embodiment 2

[0057] On the basis of Embodiment 1, this embodiment 2 also provides a method of using the farmland mulch recycling operation machine. A specific method of using the farmland mulch recycling operation machine is as follows:

[0058] S1. When it is necessary to scrape off impurities on the mulch, the first scraper 220 rotates toward the direction of the conveyor belt 111, and the first scraper 220 is suitable for scraping off impurities on the mulch on the conveyor belt 111; The air bag 214 squeezes the extrusion rod 120 so that the water outlet 223 sprays water on the mulch; the tension roller 213 squeezes the conveyor belt 111 to increase the tension of the conveyor belt 111, The cutting edge 215 cleans the inner surface of the conveyor belt 111; at the same time, when the second scraper 230 contacts the grinding roller 130, the grinding roller 130 grinds the second scraper;

[0059] S2. When the outer surface of the conveyor belt 111 needs to be cleaned, remove the plastic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com