Preparation method of thin multi-layer explosive welding composite plate

A technology of explosive welding and thin cladding, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as unbearable production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

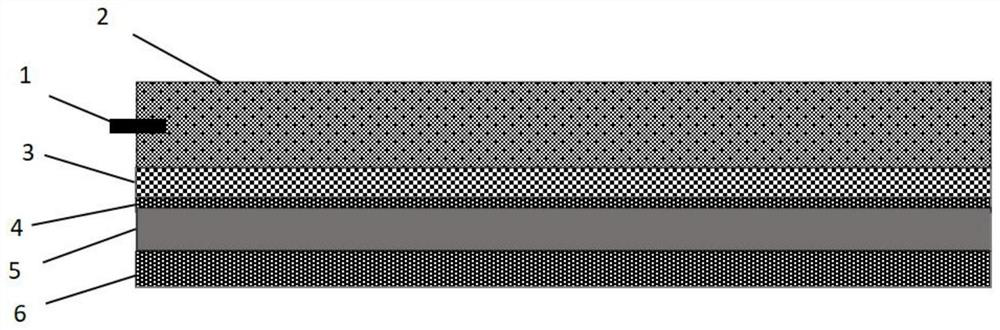

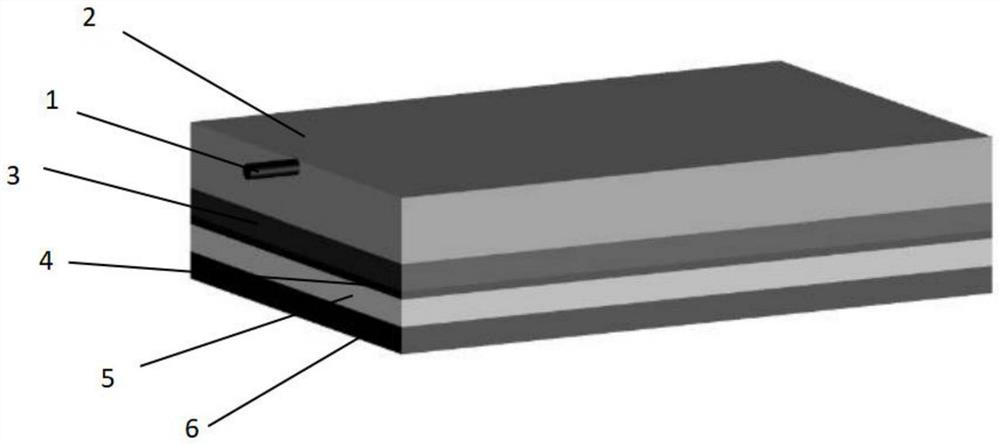

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Provided in conjunction with the accompanying drawings, a method for preparing a thin-clad explosively welded composite plate comprises the following steps:

[0015] 1) Reasonable use of sealing strips to seal and vacuum both ends of the gap between the thin cladding board (4) and the substrate (6) to form a vacuum gap environment (5);

[0016] 2) placing a buffer plate (3) on the thin doubler board (4), so that the thin doubler board (4) and the substrate (6) maintain the required initial distance;

[0017] 3) placing the configured explosive (2) on the buffer plate (3), placing the detonator (1) at the end of the explosive, putting the whole explosive welding into the explosion site, and detonating to obtain a thin clad explosive welding composite plate;

[0018] Compared with the existing metal material composite tech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com