Composite absorbing core body

A technology of absorbent core and superabsorbent resin, which is applied in the field of hygiene products, can solve the problems of composite absorbent core being thinned and hardened, not environmentally friendly, and affecting the absorption effect, so as to reduce production processes, improve production efficiency, and have superior absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

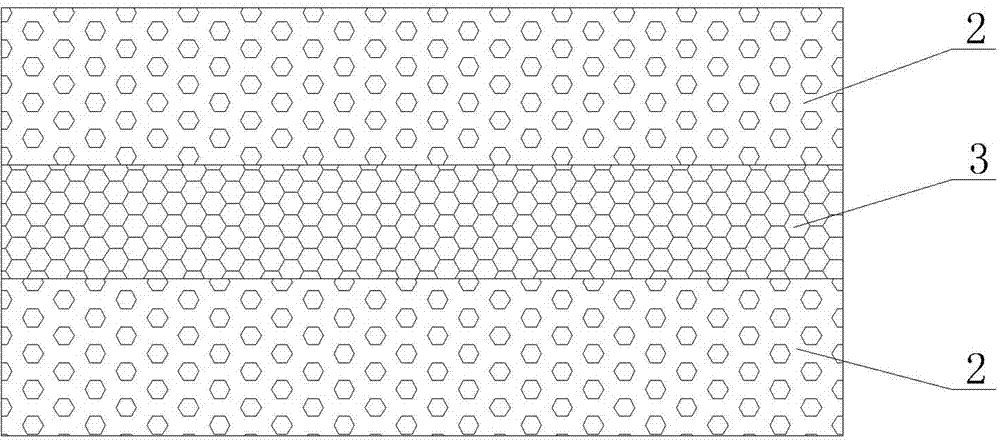

Embodiment 1

[0024] like figure 1 As shown, the fiber assembly is provided with two layers, and the two-layer fiber assembly is a fiber cotton net layer 2, and a layer of polymer superabsorbent resin 3 is provided, and this layer of polymer superabsorbent resin 3 is located on the two layers of fiber cotton net Between layers 2. Wherein, two-layer fiber cotton web layer 2 all is to utilize as the fiber cotton net that clearing machine goes out to make, and the square meter quality of described fiber cotton web layer 2 is 10 to 100 grams / square meter, is preferably 20 to 100 grams per square meter. 80 grams per square meter, and the fiber cotton net layer 2 can be made of the same core or eccentric core-sheath composite fiber whose core is made of polypropylene or polyester and the sheath is made of polyethylene, and the core is preferably made of polyester. The sheath and core are made of co-core core-sheath composite fibers made of polyethylene, and the thickness of the core-sheath compo...

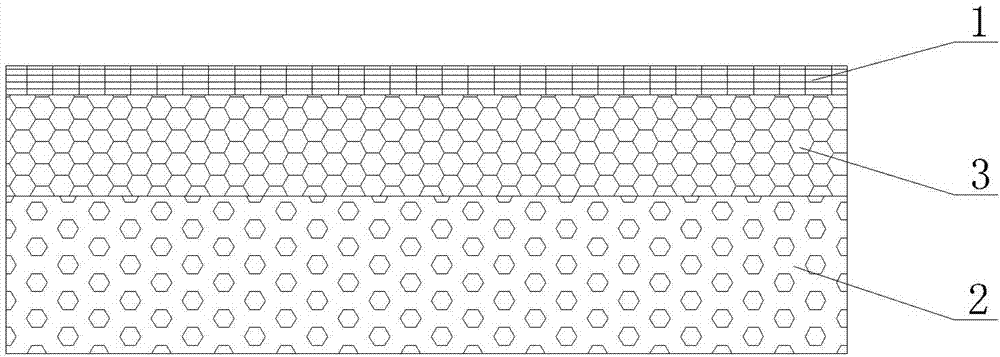

Embodiment 2

[0026] like figure 2 As shown, the fiber assembly is provided with two layers, wherein one layer of the two-layer fiber assembly is a non-woven fabric layer 1, and the other layer is a fiber cotton layer 2, and the fiber cotton layer 2 is made of two layers of fiber Cotton webs are compositely formed by hot air bonding, and a layer of polymer superabsorbent resin 3 is provided, and the layer of polymer superabsorbent resin 3 is located between the non-woven fabric layer 1 and the fiber cotton web layer 2 . Among them, the non-woven fabric layer 1 is made by such as hot air method, hot pressing method (hot roller method), air-laid method, spinning melt spraying method, etc., and the fiber cotton webs that have been sorted out by a sorting machine are preferably used. The hot air at about 150°C is blown by the hot air method, so that the fibers are melted and bonded to form a non-woven fabric layer, and the non-woven fabric layer is a hot air-laid non-woven fabric layer. And t...

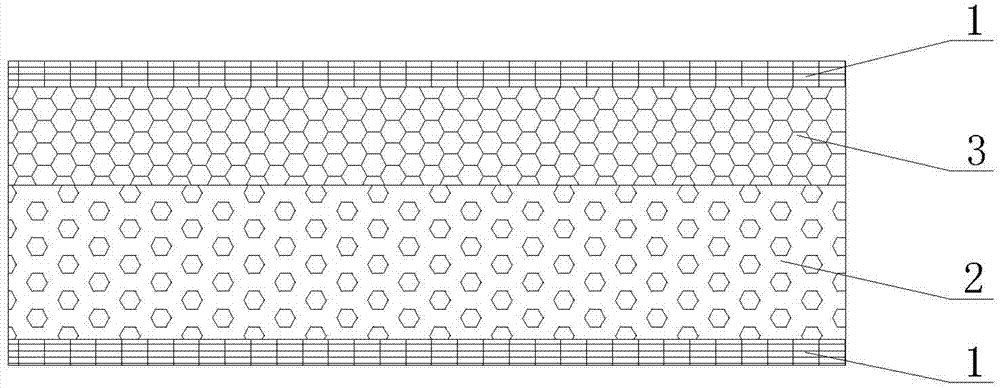

Embodiment 3

[0028] like image 3As shown, the fiber assembly is provided with three layers, the top layer and bottom layer of the three-layer fiber assembly are non-woven fabric layer 1, the middle layer is fiber cotton layer 2, and the fiber cotton layer 2 is made of two layers of fiber Cotton webs are compositely formed by hot air bonding, and a layer of polymer superabsorbent resin 3 is provided, and the polymer superabsorbent resin 3 is located between the top non-woven fabric layer 1 and the fiber cotton net layer 2 or the bottom non-woven fabric layer 1 and fiber cotton net layer 2. Among them, the non-woven fabric layer 1 is made by such as hot air method, hot pressing method (hot roller method), air-laid method, spinning melt spraying method, etc., and the fiber cotton webs that have been sorted out by a sorting machine are preferably used. The hot air at about 150°C is blown by the hot air method, so that the fibers are melted and bonded to form a non-woven fabric layer, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com