Precise and rapid repairing device for main shaft hole of steel tube rolling mill

A technology for steel pipe rolling mill and spindle hole, which is applied to feeding devices, boring/drilling devices, automatic control devices, etc., can solve the problems of inability to complete repair tasks and the inability of boring machines to move, and achieve stable guidance, accurate centerline, and enhanced structural strength. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

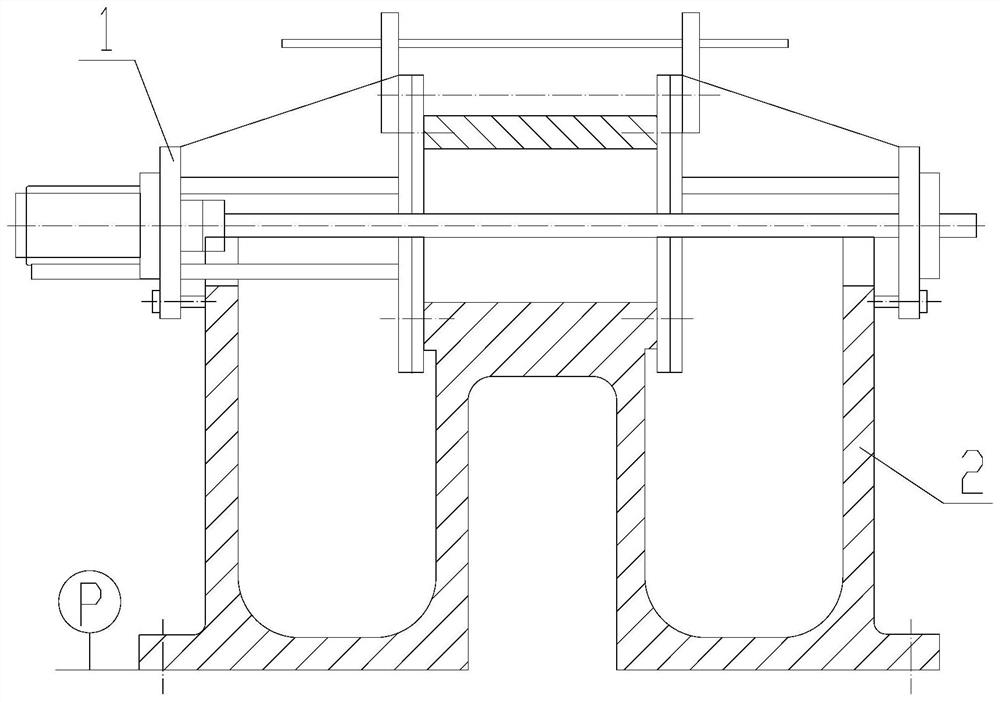

[0035] This embodiment is a precise and quick repair device for the main shaft hole of a steel pipe rolling mill. figure 1 , the two ends of the main shaft hole are used as the installation datum and fixed position of the repair device 1. This eliminates the need for large stationary boring machines for boring. Accuracy requirements such as shaft hole roundness and concentricity are fulfilled by the restoration device 1 through the "existing" benchmark of the base 2 itself.

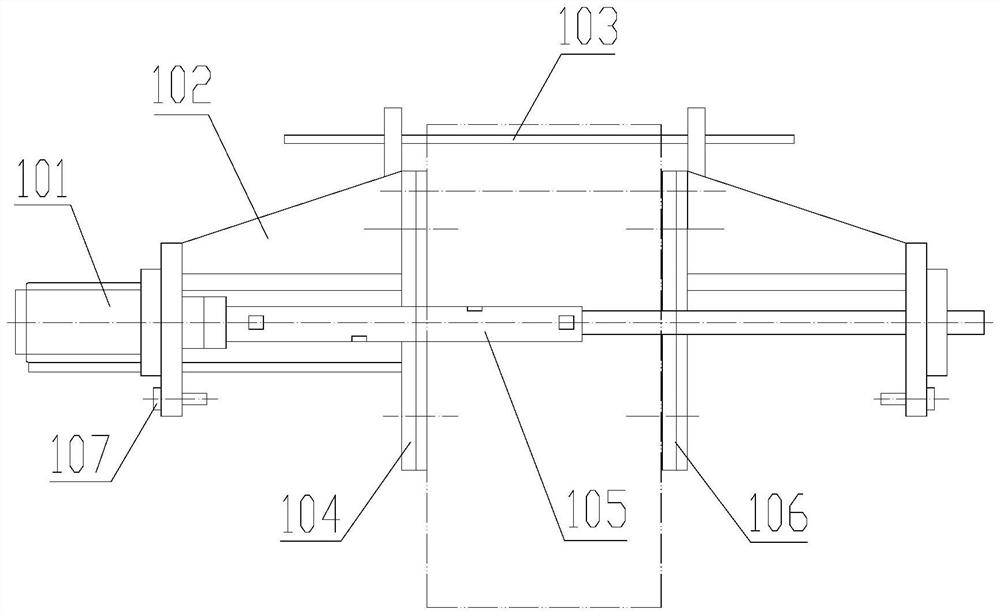

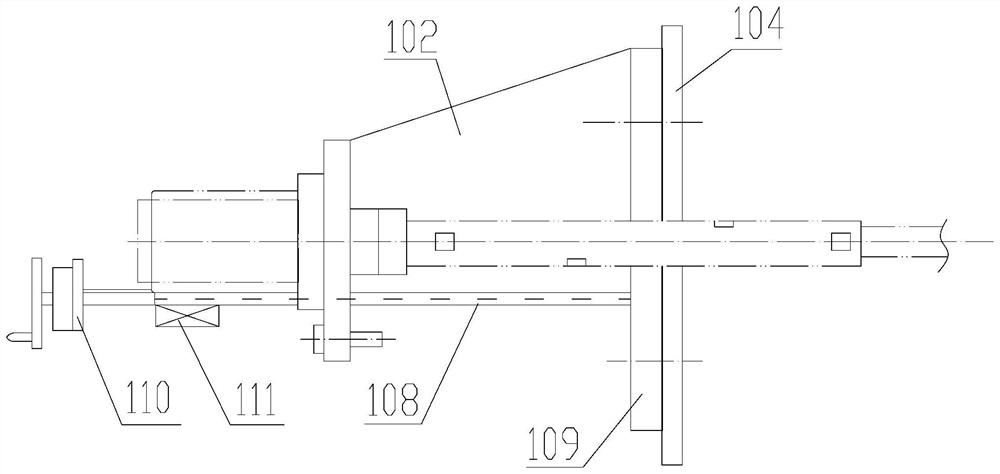

[0036] The repair device 1 comprises a first bracket 102 and a second bracket 106, such as Figure 2 to Figure 3 As shown, the first bracket 102 and the second bracket 106 are provided with a reference plate 104 matching the two ends of the main shaft hole. The existing reference holes on the two ends of the main shaft hole come f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com