Surface detection device for optical filter product

A surface detection and optical filter technology, applied in the field of optical filter detection, can solve the problems of low efficiency and manpower consumption, and achieve the effects of avoiding losses, saving time and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

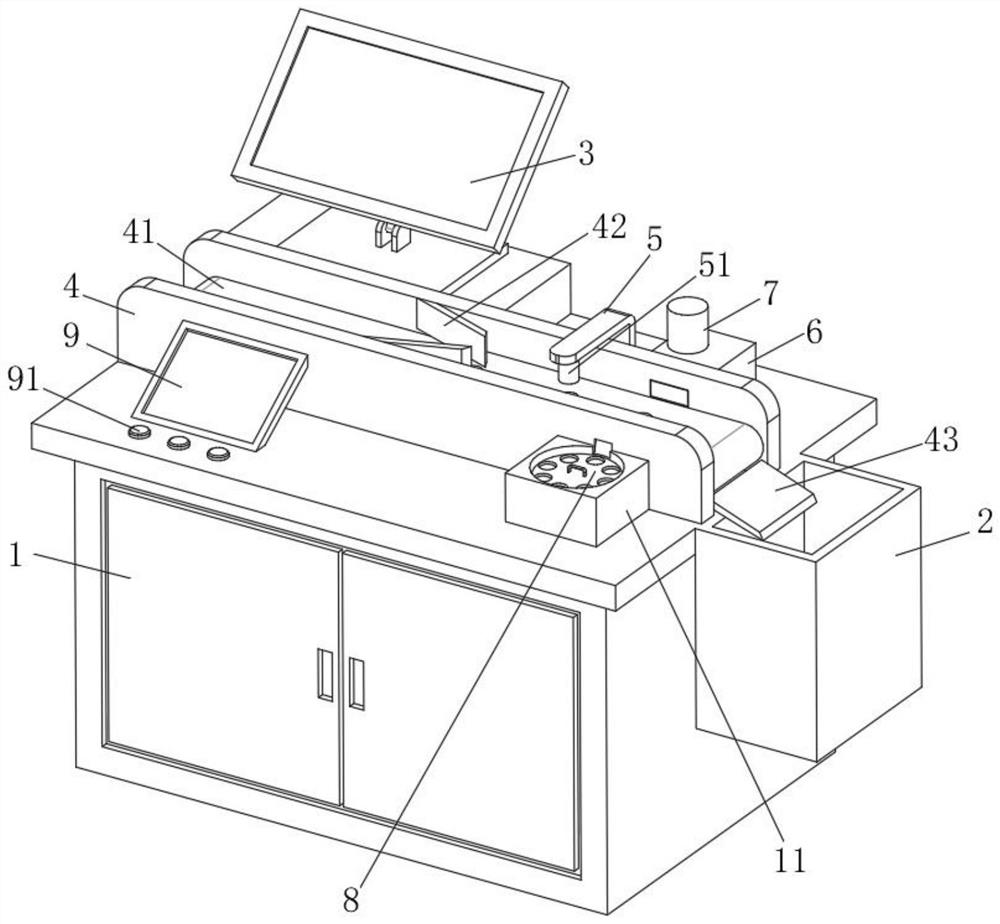

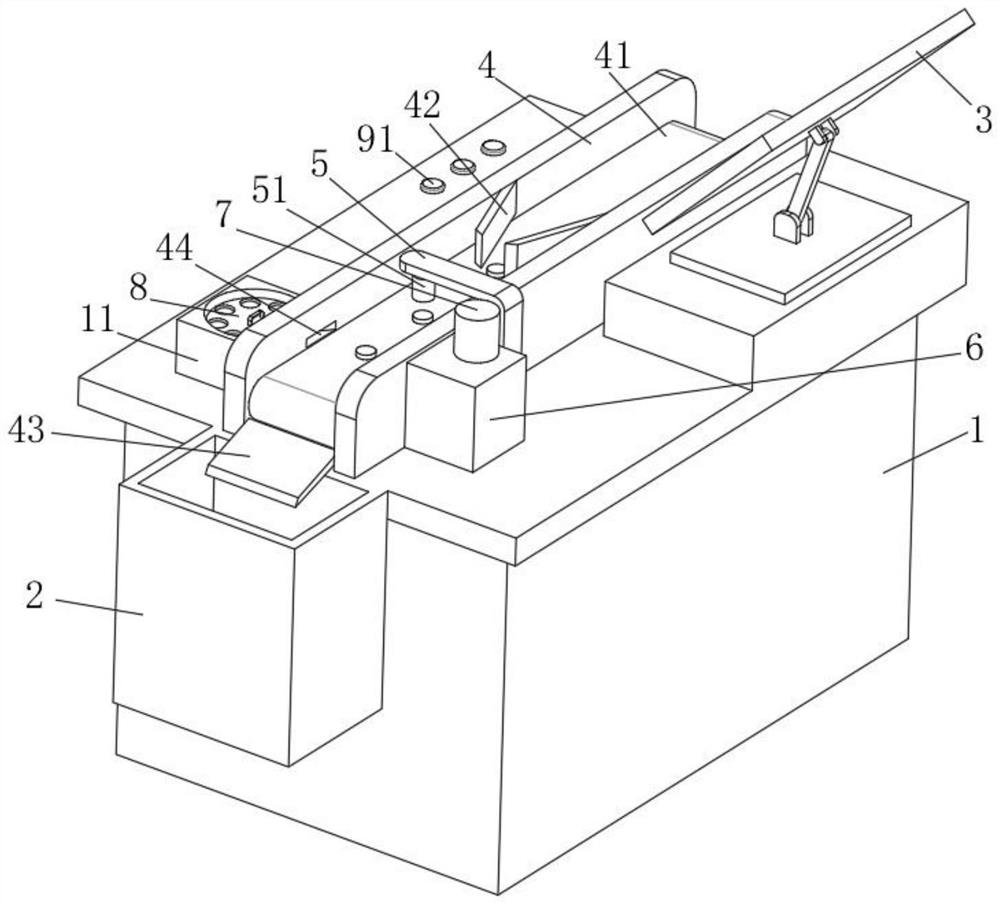

[0031] refer to Figure 1-6 , a surface detection device for optical filter products, including an operating table 1, the upper surface of the operating table 1 is communicated with a protective tube 11, and one side of the operating table 1 is fixedly installed with a defective product collection box 2, for the sorted out The defective products are collected, and the upper surface of the console 1 is fixedly equipped with a display 3 to display the situation on the surface of the optical filter. The upper surface of the console 1 is equipped with a bracket 4, and the opposite surface of the bracket 4 is rotatably connected with a conveyor belt 41 to drive the filter. In order to fix the position of the optical filter in one direction, a slide plate 43 is fixedly installed on one end of the support 4, and the slide plate 43 is arranged in the defective product collection box. 2, a trapezoidal outlet 44 is provided through one side of the bracket 4, which facilitates the remova...

Embodiment 2

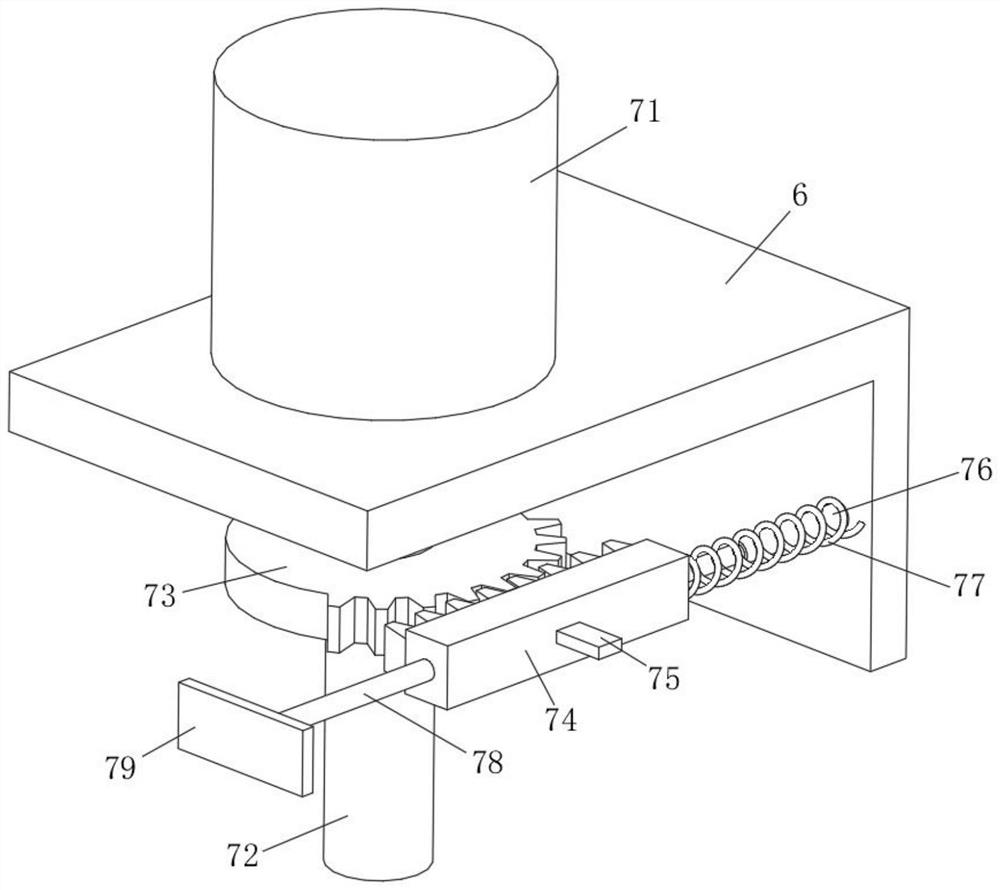

[0036] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the spring 77 is fixedly connected to the outer surface of the rack 74 , and the other end of the spring 77 is fixedly connected to the inner wall of the installation box 6 .

[0037] In this embodiment, the spring 77 will be stretched during the movement of the rack 74 , and when the meshing between the first half gear 73 and the rack 74 disappears, the reaction force generated by the spring 77 will drive the push plate 79 back to its original position.

Embodiment 3

[0039] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer surface of the power shaft 89 is fixed with a convex strip 891 , and the lower end of the power shaft 89 is rotatably connected to the inner bottom surface of the console 1 .

[0040] In this embodiment, the power shaft 89 is rotationally connected to the bottom surface of the console 1 , so that the power shaft 89 can be driven by the second half gear 87 to rotate, avoiding the jamming phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com