Fracturing propping agent roundness measuring method based on microscopic image processing

A fracturing proppant, microscopic image technology, applied in image data processing, measuring device, image analysis and other directions, can solve the problem of insufficient basis, inability to measure the properties and quality of fracturing proppant particles, and work efficiency cannot be effectively guaranteed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

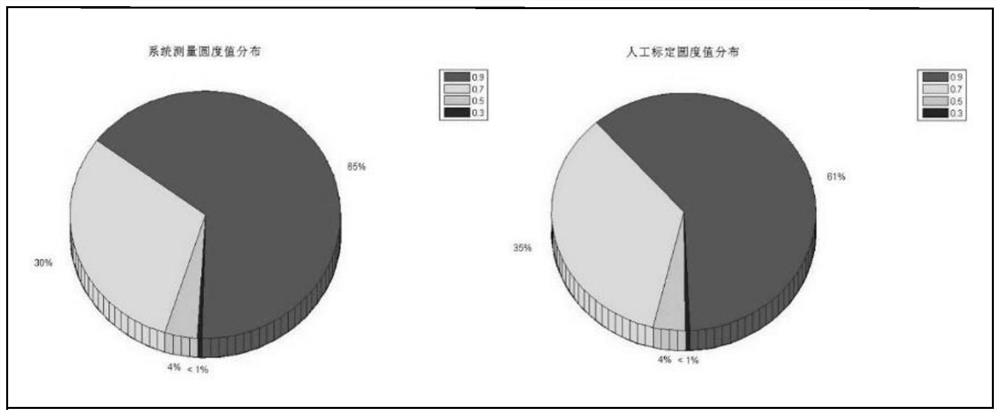

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below, which is an explanation of the present invention rather than a limitation.

[0071] see figure 1 , a method for measuring roundness of fracturing proppants based on microscopic image processing, comprising the following steps:

[0072] 1) Corner detection is performed on each processed fracturing proppant particle edge image;

[0073] 2) If no corner point is detected, it is determined that the roundness of the fracturing proppant particles is 0.9, otherwise proceed to step 3);

[0074] 3) Divide the edge curve of each fracturing proppant particle into several sections, and at the same time, each section of the curve is fitted with a high-order curve with the highest coefficient of determination to obtain several fitted curve equations;

[0075] 4) For the corner point detected in step 1), calculate the radius of curvature of the corner point according to formula (1) according to the sequence number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com