Electronic proportioning valve and control system

A proportional control valve and control system technology, applied in the field of proportional valves, can solve the problems of low control precision, high equipment cost, many components, etc., and achieve the effects of high control precision, simple structure, flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

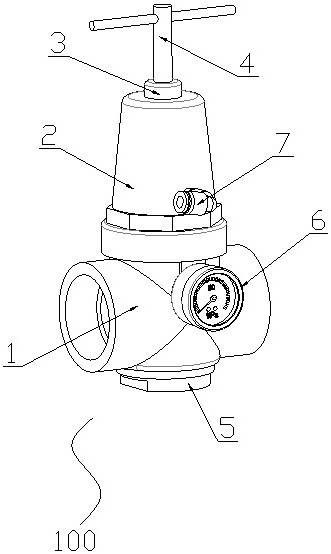

[0029] like figure 1 As shown, the first embodiment provides an electronic proportional regulating valve, which includes a proportional valve body 100 ; the proportional valve body 100 includes a valve body 1 and a conical upper cover 2 .

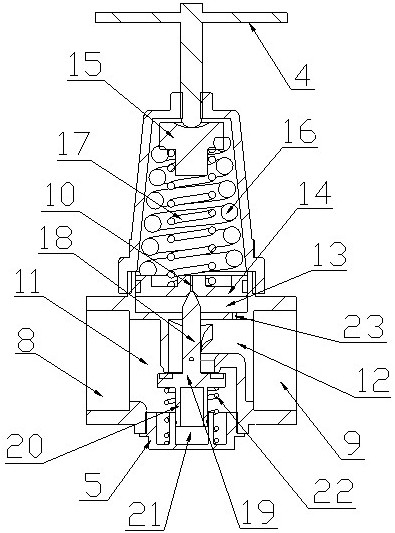

[0030] In this embodiment, specifically, an air inlet chamber 11 and an air outlet chamber 12 that communicate with each other are formed inside the valve body 1; The valve core assembly of high degree; the bottom of the valve body 1 is embedded with a bottom cover 5; the valve core assembly is elastically mounted on the bottom cover 5; the top of the valve body 1 is formed with a piston cavity 13; A piston 14 is slidingly installed in the piston cavity 13; one end of the spool assembly extends into the piston cavity 13 and is connected with the piston 14 in conflict; the upper cover 2 is provided with a preset valve for adjusting the preset threshold of the piston 14. pressure device; the side end of the upper cover 2 is provided with an ...

Embodiment 2

[0033] like Figure 1-3 As shown, this embodiment 2 contains all the technical features of embodiment 1, the difference is that: the valve core assembly includes a top post 18, a blocking plug 19 and a limit cylinder 20 from top to bottom; the top post 18 is far away from One end of the blocking plug 19 is a pointed structure; the pointed structure passes through the side wall of the valve body 1 and extends into the piston chamber 13; the pointed structure is in conflicting connection with the piston 14; the blocking plug 19 is used to open or close the intake air The connecting channel between the cavity 11 and the air outlet cavity 12; the inside of the bottom cover 5 has a limiting cavity 21; the limiting cylinder 20 is slidably installed in the limiting cavity 21; the bottom cover 5 and the blocking plug 19 There is a retaining spring 22 between them; when the spool assembly moves upward, the blocking plug 19 gradually reduces the opening of the electronic proportional re...

Embodiment 3

[0038] refer to Figure 4 , this embodiment 3 provides a control system, the system includes all the technical features of the above-mentioned embodiment 1 and embodiment 2, the difference is: the system also includes a distribution gas tank 200, a main switch valve 300 and a tee joint 400; The first port of the three-way joint 400 is connected to the main switch valve 300; the second port of the three-way joint 400 is connected to the air inlet 8 of the valve body 1; the air outlet 9 of the valve body 1 is connected to the distribution The gas tank 200 is connected; the main switch valve 300 is connected to the gas source; the distribution gas tank 200 is provided with several electromagnetic valve groups 900 for supplying gas to the gas unit; the outer wall of the distribution gas tank 200 is provided with a pressure Transmitter 500; the control system also includes a PLC control unit 600, a PID controller 700 and an electrical proportional control valve 800; the pressure tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com