Titanium alloy drill rod

A titanium alloy, drill pipe technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of low joint fatigue performance, high repair rate, poor anti-galling ability of threads, etc., to achieve high fatigue performance, increase Contact area and effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

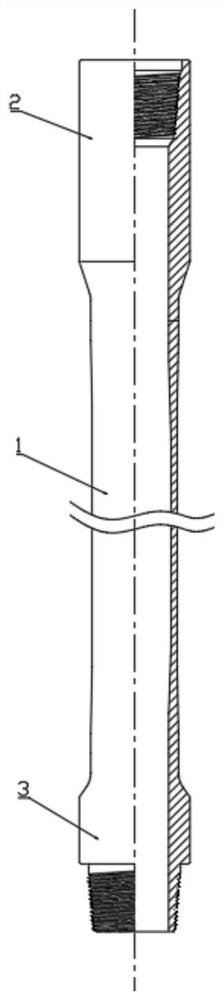

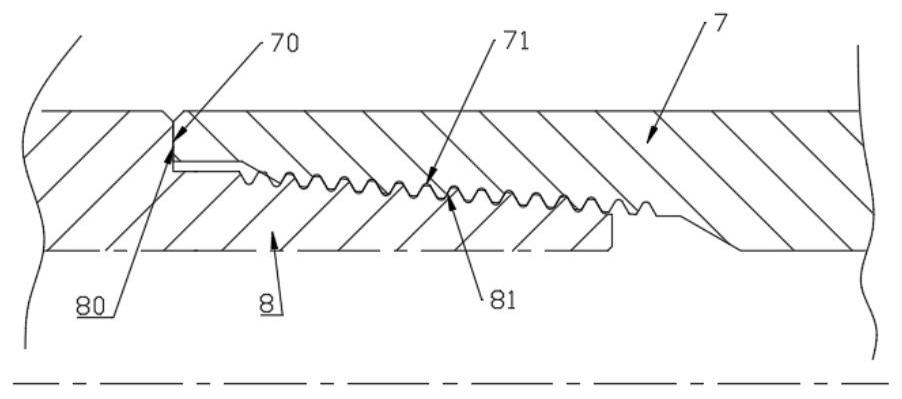

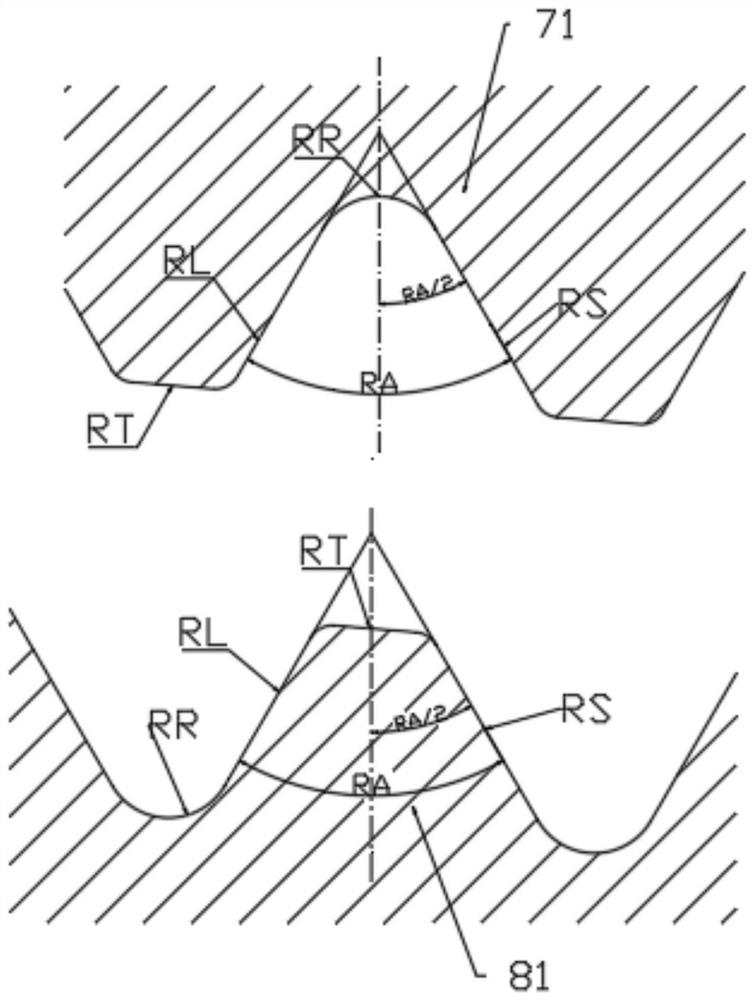

[0033] Such as Figure 4-Figure 6As shown, a titanium alloy drill pipe includes a drill alloy drill pipe body 1, an internally threaded joint 2 and an externally threaded joint 3 at both ends of the titanium alloy drill pipe body, and the internally threaded joint 2 consists of a welding diameter area 21, a hanging Card area 22, tongs area 23 and internal thread area 24, wherein internal thread area 24 includes internal thread outer end surface 241, tapered internal thread segment 242, internal thread internal end surface 243; Area 31, elevator area 32, tongs area 33 and external thread area 34, wherein the external thread area 34 includes an external thread outer end surface 341, a tapered external thread segment 342 and an external thread internal end surface 343; the internal thread The region 24 is processed with a tapered coarse pitch wedge-shaped dovetail internal thread B, and the external thread region 34 is processed with a tapered coarse pitch wedge-shaped dovetail e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com