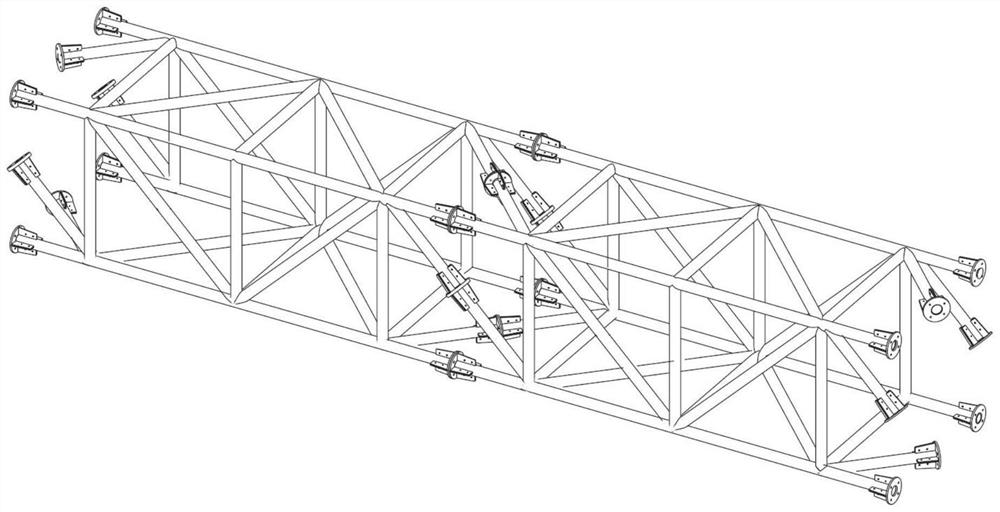

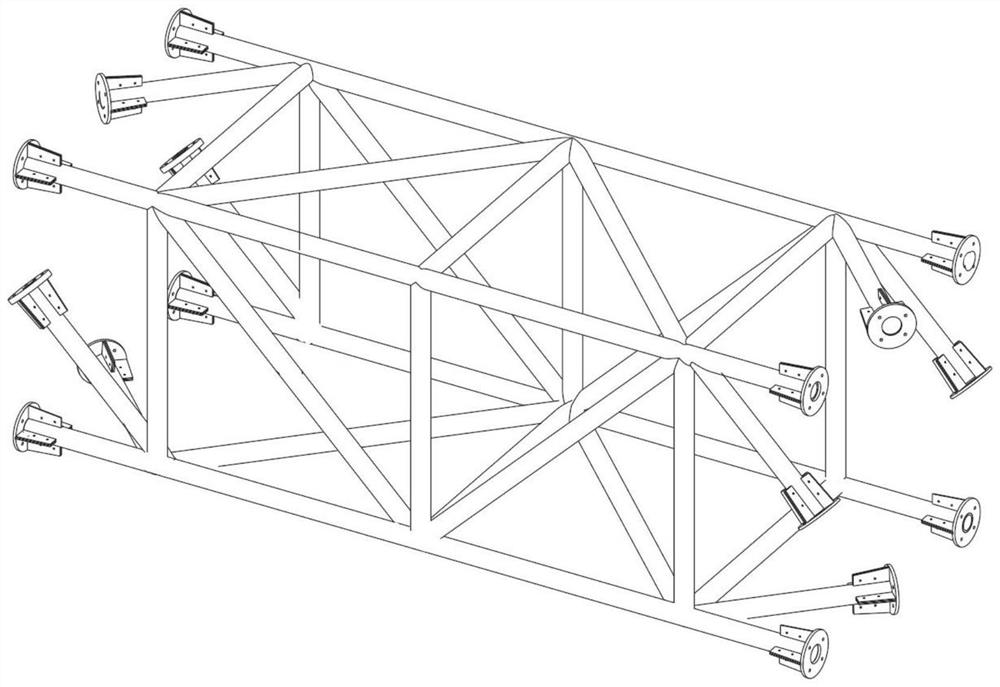

Assembly type truss joint, assembly type truss structure and assembly method

A truss structure and assembly technology, applied in the direction of truss structure, truss beam, building structure, etc., can solve the problems of difficult control of welding quality, waste of manpower and material resources, and many skilled workers, so as to improve construction efficiency and reduce labor costs. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] In this embodiment, an assembled truss node is provided, including:

[0042] The flange plate has a plurality of bolt holes and a plurality of rectangular holes, and one side of the flange plate is set to be welded with an end surface of the rod and an end surface of the first connecting piece, wherein the plurality of bolt holes are located at The outer side of the connecting position between the flange plate and the rod and the first connecting piece, the plurality of rectangular holes are located between the two first connecting pieces;

[0043] A plurality of first connecting pieces, including three connecting end surfaces, wherein the first end surface is welded to the rod, the second end surface is welded to the flange plate, and the third end surface is bolted to the second connecting piece, wherein the third connection The end face has bolt holes;

[0044] A plurality of second connecting pieces have bolt holes, and each of the second connecting pieces is confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com