Method for in-place installation of water supply pipeline in lower belly of bridge

A technology for water supply pipes and installation methods, which can be applied to bridges, bridge parts, bridge construction, etc., and can solve the problem of high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with accompanying drawing:

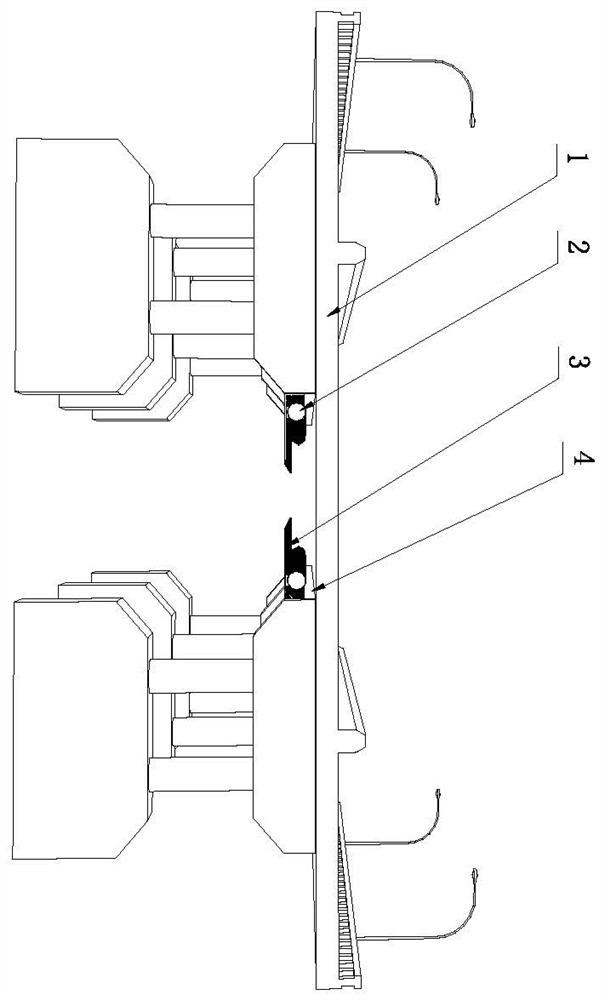

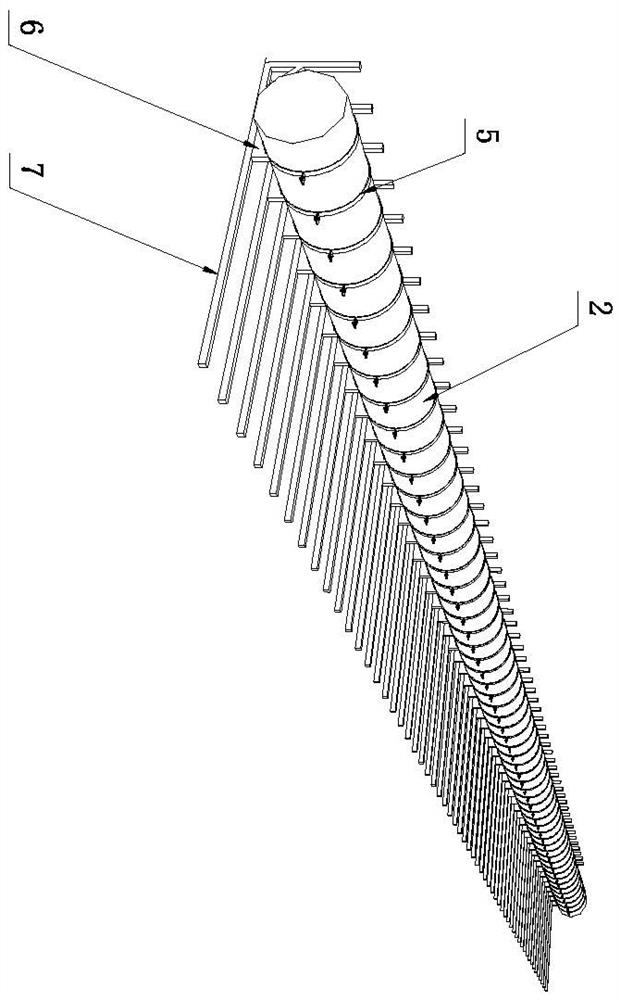

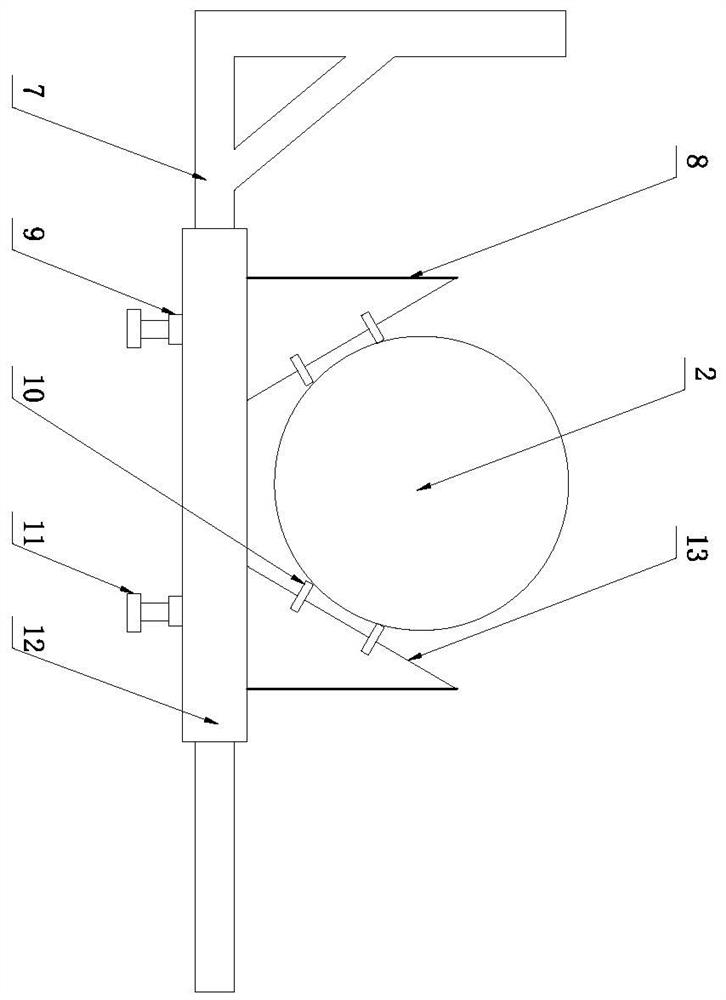

[0043] like Figure 1-4 A method for installing a water supply pipeline in place in the underbelly of a bridge includes the following steps:

[0044] Step 1, pre-embed multiple steel plates on the girder plate in the underbelly of bridge 1, and weld the fixed bracket 3 on the pre-embedded steel plates:

[0045] A number of steel plates are pre-embedded on the girder plate in the lower abdomen of the bridge 1. The plane size and thickness of each steel plate meet the requirements of the bracket installation. One steel plate is set at a certain distance, and the fixed bracket 3 for installing the pipeline 2 is welded to the embedded steel plate. 4. When installing the fixed bracket 3, the channel steel is cut according to the size of the drawing and prefabricated. The overall bracket is L-shaped and composed of channel steel. The two channel steels of the fixed bracket 3 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com