Water-based woodware white primer for full-open white coating and preparation method of water-based woodware white primer

A water-based, fully open technology, applied in the field of coatings, can solve the problems of discontinuous and unnatural wood grain, poor water resistance of paint film, insufficient white space of wood grain, etc., to achieve good anti-oxidation, good water resistance and mildew resistance. , The effect of saving construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention provides a technical solution: a permutable aqueous wood, aqueous wood, including a group and a group, including the following mass percent components: hydroxyacry acid emulsion 35%, pH regulator 0.2% 1.1% of the antifoaming agent, 3% film formulation, 1.3% dispersant, 2% of the anti-sediment, 30% titanium powder, 5% talc, thickener 0.2%, wetting agent 2%, sterilizing mildew The agent is 0.3%, the weight calcium is 3%, the aqueous level 1%, the acrylic emulsion is 2%, the resin is 1%, and the remainder is water. .

[0025] The wetting agent is one or two of the polyether modified siloxanes and the acetylene diol; the antibodies are one or two of the modified urea solution and the polyamide wax mix. .

[0026] The thickener is a hydrophobic modified nonionic polyurethane copolymer mixed with any of the above ratios.

[0027] The film forming aid is dipropylene glycol methyl ether, dipropylene glycol butyl ether and alkoxide twelve.

[0028] The curing a...

Embodiment 1

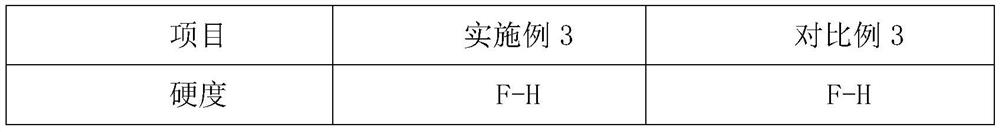

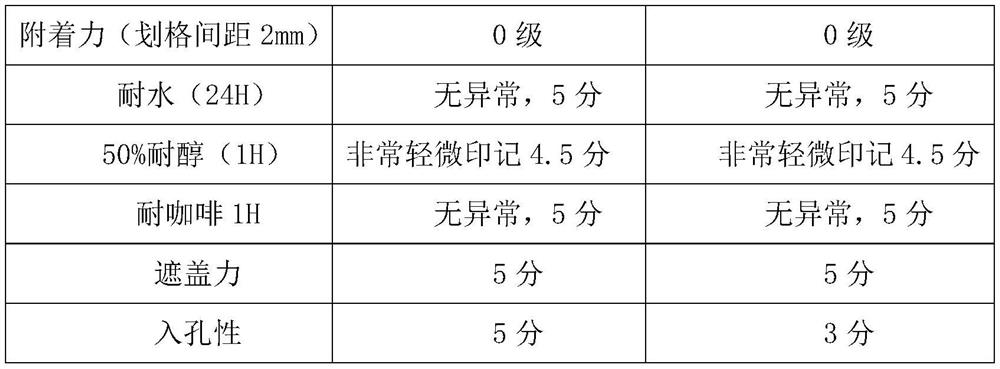

[0040] Example 1 and Comparative Example 1 The physical and chemical performance test results are as follows:

[0041] project Example 1 Contrast 1 hardness F-H 2B-B Adhesion (2mm in planning) Level 0 Level 0 Water resistance (24h) No abnormality, 5 points Mild imprint, 4 points 50% melting alcohol (1H) Very slight imprint 4.5 points Minor imprint 4 points Coffee resistant 1h No abnormality, 5 points Mild imprint, 3 points Hide 5 points 5 points Inlet 5 points 4 points

Embodiment 2

[0045] A permanent open white coating water-based wood-based white primer, including a group and group B, and a moiety comprising the following mass percent component: 38% hydroxyacrylate, 0.2% pH regulator, 1.1% defoaming agent, 3%, dispersant 1.3%, anti-sediment 1-3%, titanium powder 30%, talc powder, 0.2% thickener, 2% of the wetting agent, 0.3% sterilizing agent, heavy calcium 3%, aqueous graft agent 0.5-1.5%, acrylic emulsion 2%, resin 1%, the remainder is water, and the Group B includes the following mass percent components: aqueous isocyanate curing agent 80%, solvent 20%.

[0046] The wetting agent is one or both of the polyether modified siloxanes and the acetylene glycol; the anti-sedent is a modified urea solution and a polyamide wax mixed in any ratio.

[0047]The thickener is a hydrophobic modified nonionic polyurethane copolymer mixed with any of the above ratios.

[0048] The film forming aid is dipropylene glycol methyl ether, dipropylene glycol butyl ether and alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com