Injection machine and workpiece preparation method using same

A technology for injection machines and mixing components, which is applied in the field of metal powder metallurgy, can solve problems such as the influence of product molding quality, and achieve the effects of accelerated time, high quality, and uniform materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

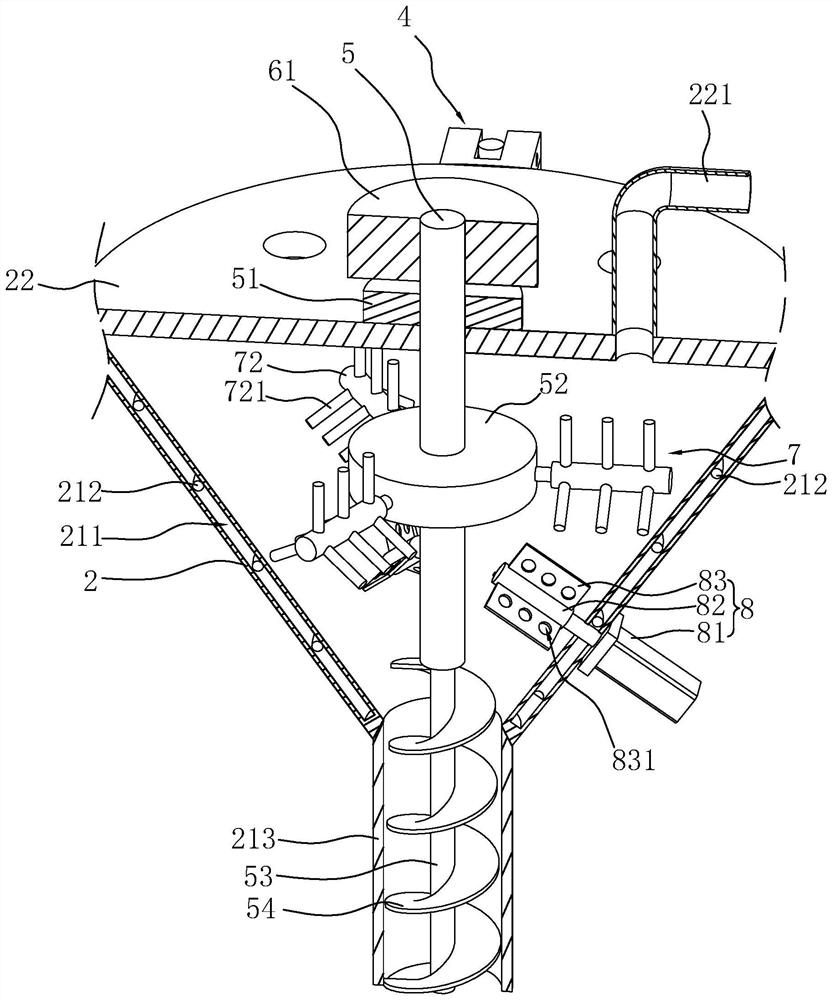

[0037] The following is attached Figure 1-5 The application is described in further detail.

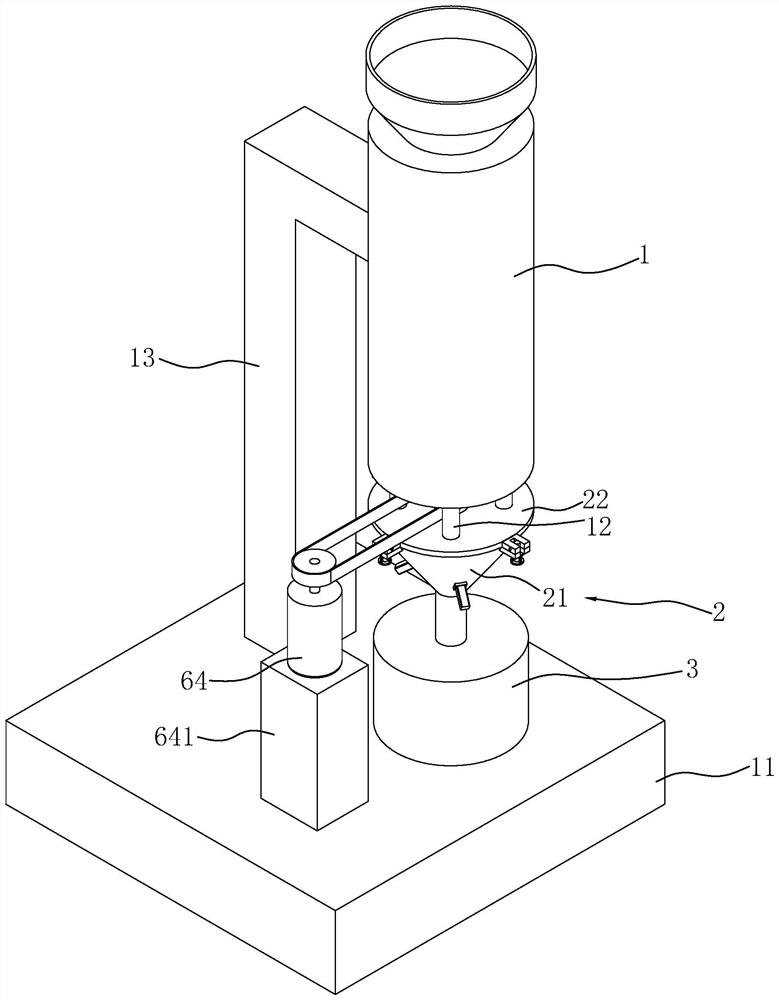

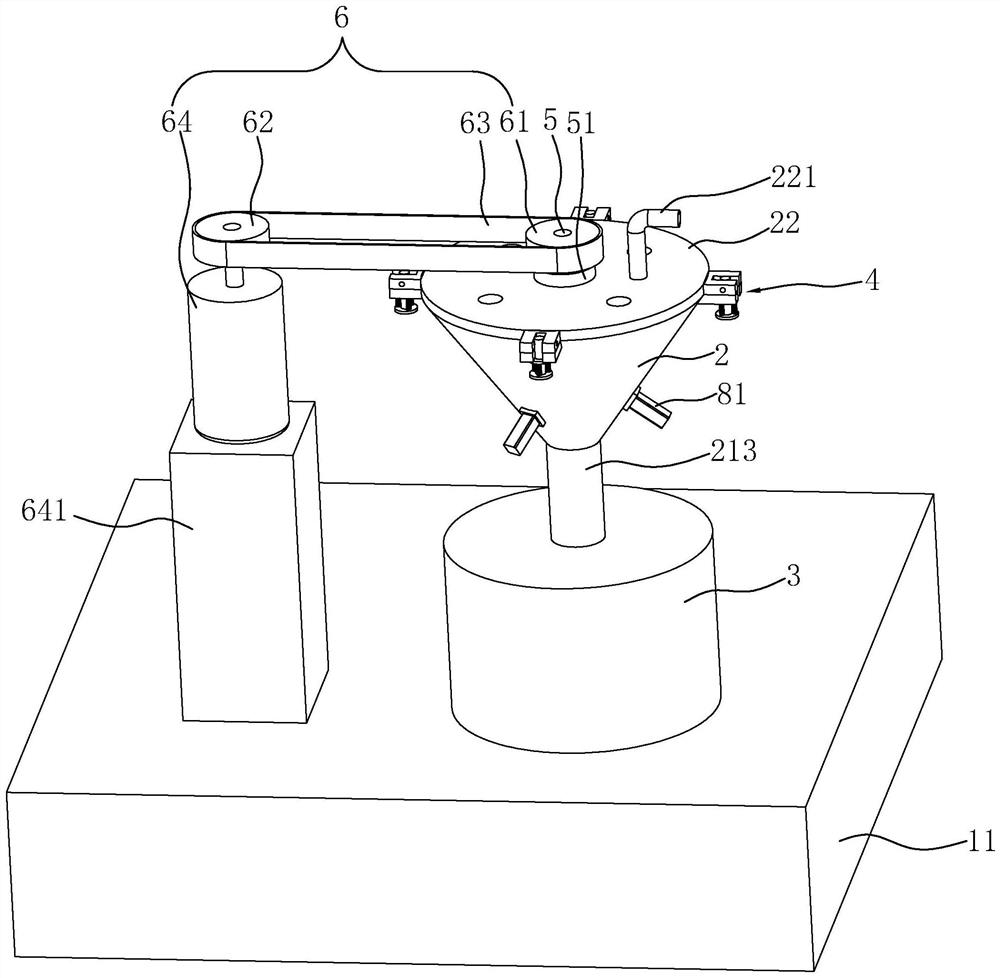

[0038] The embodiment of the present application discloses an injection machine. refer to figure 1 The injection machine includes an injection machine body 1 and an operating table 11. A stirring mechanism 2 is connected below the injection machine body 1. A mold clamping mechanism 3 is connected below the stirring mechanism 2. The mold clamping mechanism 3 is fixed on the upper surface of the operating table 11. A support rod 13 is fixed on the upper surface of the console 11 , and the end of the support rod 13 away from the console 11 is fixed to the side wall of the injection machine body 1 .

[0039] When injecting the material, first put the material into the injection machine body 1, the injection machine body 1 mixes and heats the material, and then the injection machine body 1 injects the material into the stirring mechanism 2, and the stirring mechanism 2 performs a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com