Acetylene hydrochloride gold-based catalyst and preparation method thereof

An acetylene hydrochloride gold-based, catalyst technology, applied in physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, hydrogen halide addition preparation, etc., can solve the problem of high cost of double precious metals and unfavorable industrialization Production, unsatisfactory stability of gold-based catalysts, etc., to reduce the preparation cost and improve the catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

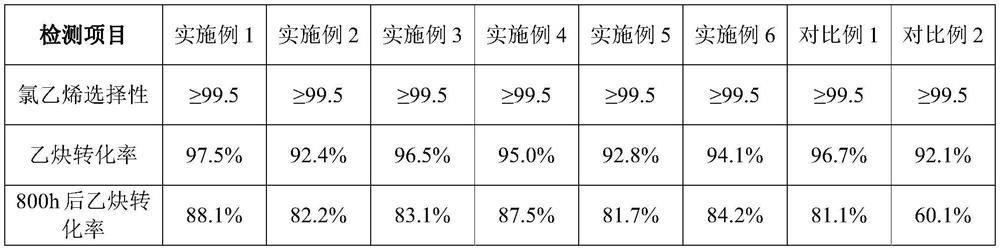

Examples

Embodiment 1

[0040] Embodiment 1 A kind of preparation method of acetylene hydrochloride gold-based catalyst

[0041] Take the following steps:

[0042] Weigh 50g of wood-based activated carbon, immerse the activated carbon in 200mL of 5%wt hydrochloric acid solution for 5h, filter, wash with deionized water until the pH of the aqueous solution is close to 5, and dry at 120°C for 8h to obtain a precursor; mix 50g of the precursor with 500mL of 15 % dichlorophenylphosphorus aqueous solution was mixed and stirred for 5 hours, and dried at 120°C for 12 hours to obtain modified activated carbon; after that, 40 g of modified activated carbon was taken, and the mixed solution A was added dropwise to the modified activated carbon, and then transferred to Dry in an oven at 120°C for 12 hours to obtain the Au-SCN / AC(P1) catalyst;

[0043] The preparation method of the mixed solution A is as follows: 0.08g of chloroauric acid and 2g of potassium thiocyanate were weighed and dissolved in 30mL of dei...

Embodiment 2

[0045] Embodiment 2 A kind of preparation method of acetylene hydrochloride gold-based catalyst

[0046] Take the following steps:

[0047] Weigh 50g of wood-based activated carbon, immerse the activated carbon in 200mL 5%wt hydrochloric acid solution for 5h, filter, wash with deionized water until the pH of the aqueous solution is close to 5, and dry at 120°C for 8h to obtain a precursor; mix 50g of the precursor with 15% Mix and stir 500mL of di-tert-butylphosphorus chloride aqueous solution for 5 hours, dry at 120°C for 12 hours to obtain modified activated carbon; finally obtain 40g of modified activated carbon, add the mixed solution A to the modified activated carbon drop by drop, and impregnate for 4 hours Afterwards, it was transferred to an oven and dried at 120°C for 12 hours to obtain the Au-SCN / AC(P2) catalyst.

[0048] The preparation method of the mixed solution A is as follows: 0.08g of chloroauric acid and 2g of potassium thiocyanate were weighed and dissolved...

Embodiment 3

[0050] Embodiment 3 A kind of preparation method of acetylene hydrochloride gold-based catalyst

[0051] Take the following steps:

[0052] Weigh 50g of wood-based activated carbon, immerse the activated carbon in 200mL of 5%wt hydrochloric acid solution for 5h, filter, wash with deionized water until the pH of the aqueous solution is close to 5, and dry at 120°C for 8h to obtain a precursor; mix 50g of the precursor with 500mL of 15 % tetrakis hydroxymethyl phosphorus sulfate aqueous solution was mixed and stirred for 5 hours, and dried at 120°C for 12 hours to obtain modified activated carbon; finally, 40 g of modified activated carbon was obtained, and the mixed solution A was added dropwise to the modified activated carbon, and after immersion for 4 hours Transfer to an oven and dry at 120°C for 12 hours to obtain the Au-SCN / AC(P3) catalyst.

[0053]The preparation method of the mixed solution A is as follows: 0.08g of chloroauric acid and 2g of potassium thiocyanate were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com