Gasket for electrolytic cell and electrolytic cell using same

An electrolytic cell and gasket technology, which is applied in the electrolysis process, electrolysis components, engine sealing, etc., can solve the problems related to the inability to prevent the early damage of the diaphragm and the durability of the diaphragm, and achieve high practical value, excellent durability and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

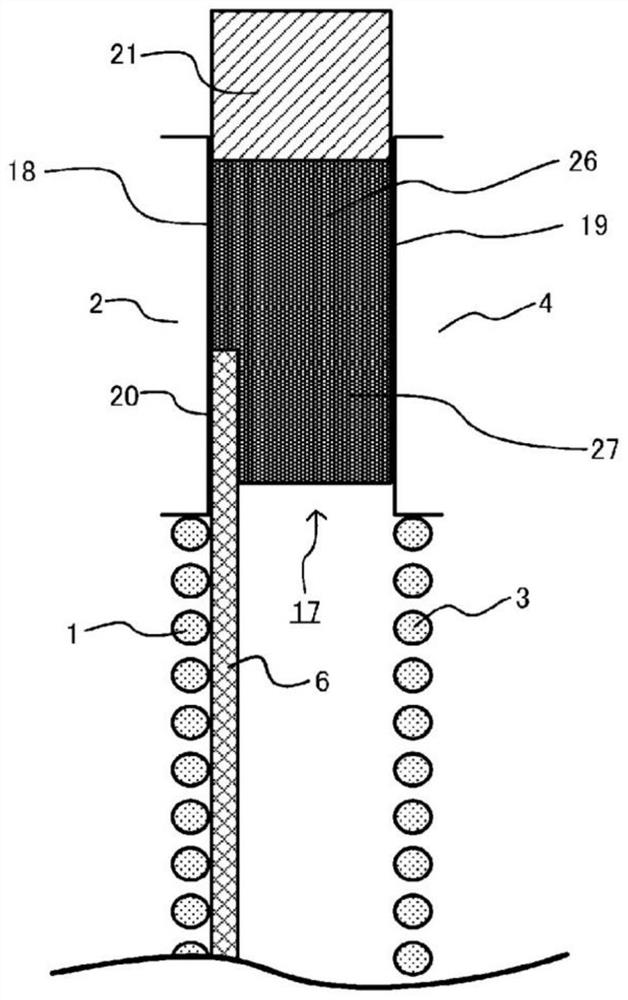

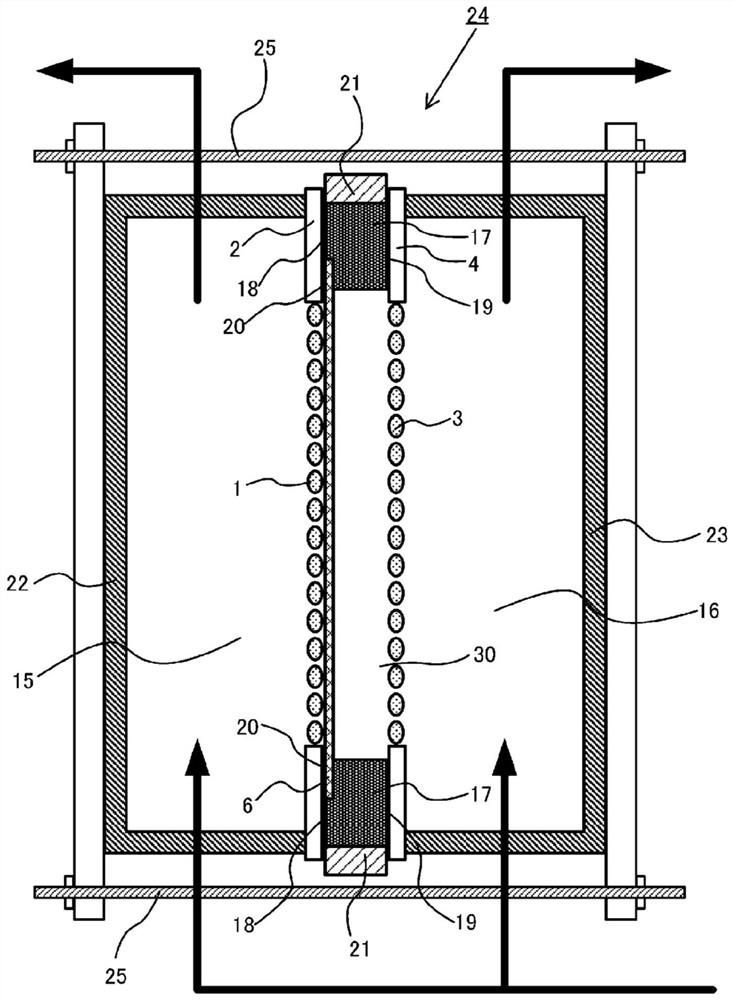

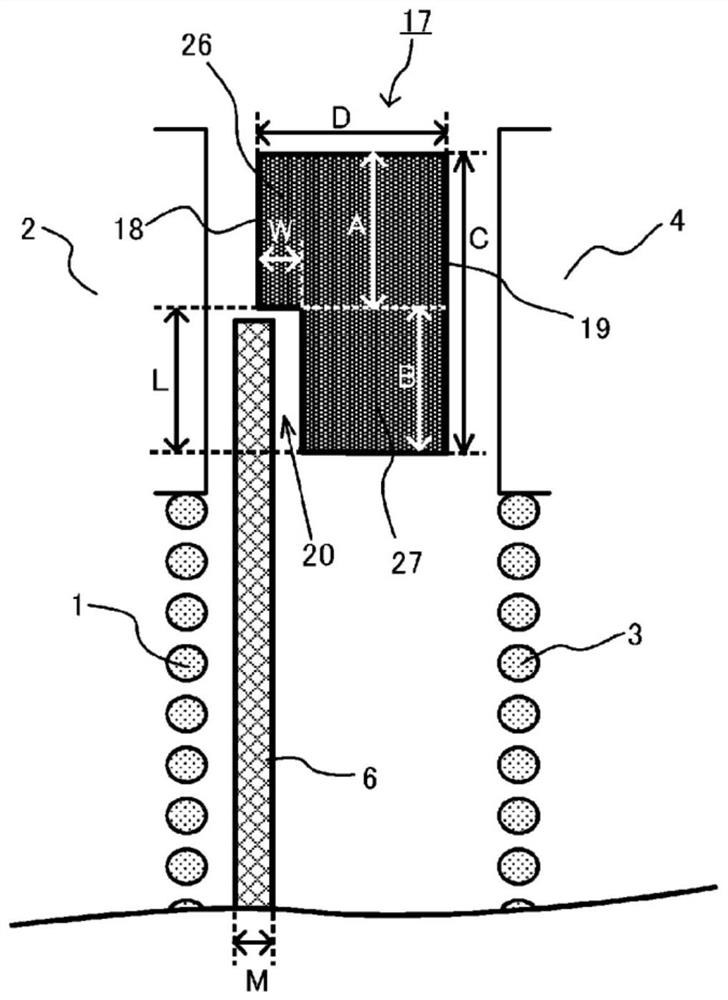

[0072] figure 2 It is a schematic sectional view for demonstrating the 1st Embodiment of the gasket for electrolysis of this invention used for the alkaline water electrolytic cell 24 which is an electrolytic cell. In the alkaline water electrolysis performed using the alkaline water electrolytic tank 24, 25% by mass to 35% by mass of KOH aqueous solution or NaOH aqueous solution is used as an electrolytic solution. When the electrolytic solution is supplied to the anode chamber 15 and the cathode chamber 16 for electrolysis, the electrolytic solution and oxygen gas are discharged from the anode chamber 15 to the outside of the system, and the electrolytic solution and hydrogen gas are discharged from the cathode chamber 16 to the outside of the system. The discharged electrolytic solution is mixed outside the system and circulated to the anode chamber 15 and the cathode chamber 16 to perform continuous electrolysis.

[0073] Such as figure 2 As illustrated, the alkaline w...

no. 2 Embodiment approach 〕

[0092] In the first embodiment, an example in which the notch portion 20 is provided in the notch forming portion 27 of the first surface 18 of the gasket 17 in contact with the anode-side metal frame 2 has been described. In the second embodiment, a notch forming part 27 is provided on the second surface 19 of the gasket 17 opposite to the above, which is in contact with the cathode side metal frame 4, and a notch part 20 (not shown) is formed. Show). In this example, the filled portion 26 of the gasket 17 above the center of the second surface 19 is brought into surface contact with the cathode-side metal frame 4, while the entire first surface 18 of the gasket 17 is brought into contact with the cathode side metal frame 4. The two surfaces of the metal frame on the anode side are in contact. In this case, the cathode-side metal frame 4 and the cathode 3 are arranged in the same plane. Therefore, the diaphragm 6 whose edge is accommodated and held in the notch 20 provided ...

no. 3 Embodiment approach 〕

[0095] In the third embodiment, in addition to the structure of the first embodiment or the second embodiment, a member in which the surface of the anode 1 on the side of the separator 6 is coated with an anode activation catalyst is used, and the cathode 3 is used on the side of the separator 6 A component made of a cathode-activated catalyst coated on its surface. With such a configuration, it is possible to achieve high performance of the electrolytic cell. In addition, in order to increase the performance of the electrolytic cell of the present invention, it is preferable to install the anode-side fine mesh 28 coated with an anode catalyst active coating on the surface of the anode 1 on the side of the diaphragm 6 and / or to mount and implement the anode-side fine mesh 28 on the surface of the cathode 3 on the side of the diaphragm 6. The cathode catalyst active coated cathode side fine mesh 29 is provided.

[0096] In order to further improve the performance of the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com