LED display module and manufacturing method

A technology for display modules and manufacturing methods, applied to identification devices, instruments, semiconductor devices, etc., can solve the problems of high design difficulty, large product size, and low product yield, so as to reduce design difficulty, reduce finished product size, The effect of reducing the number of pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

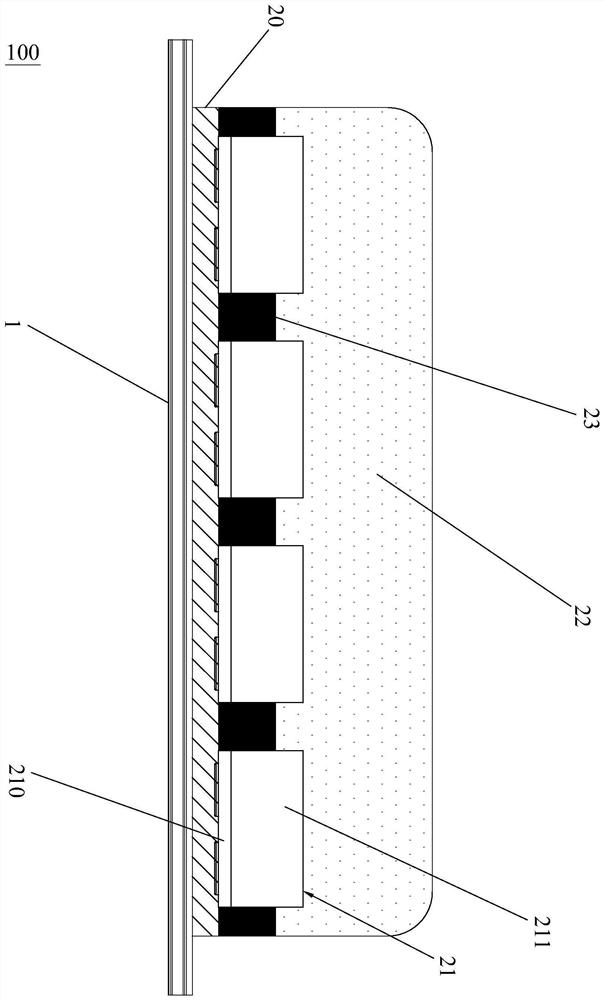

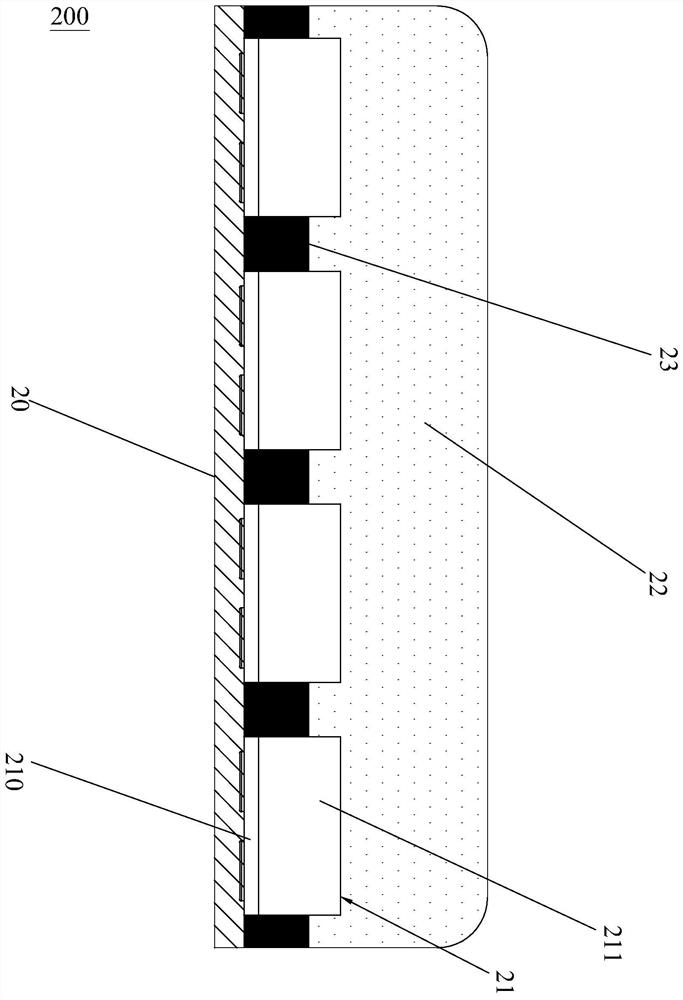

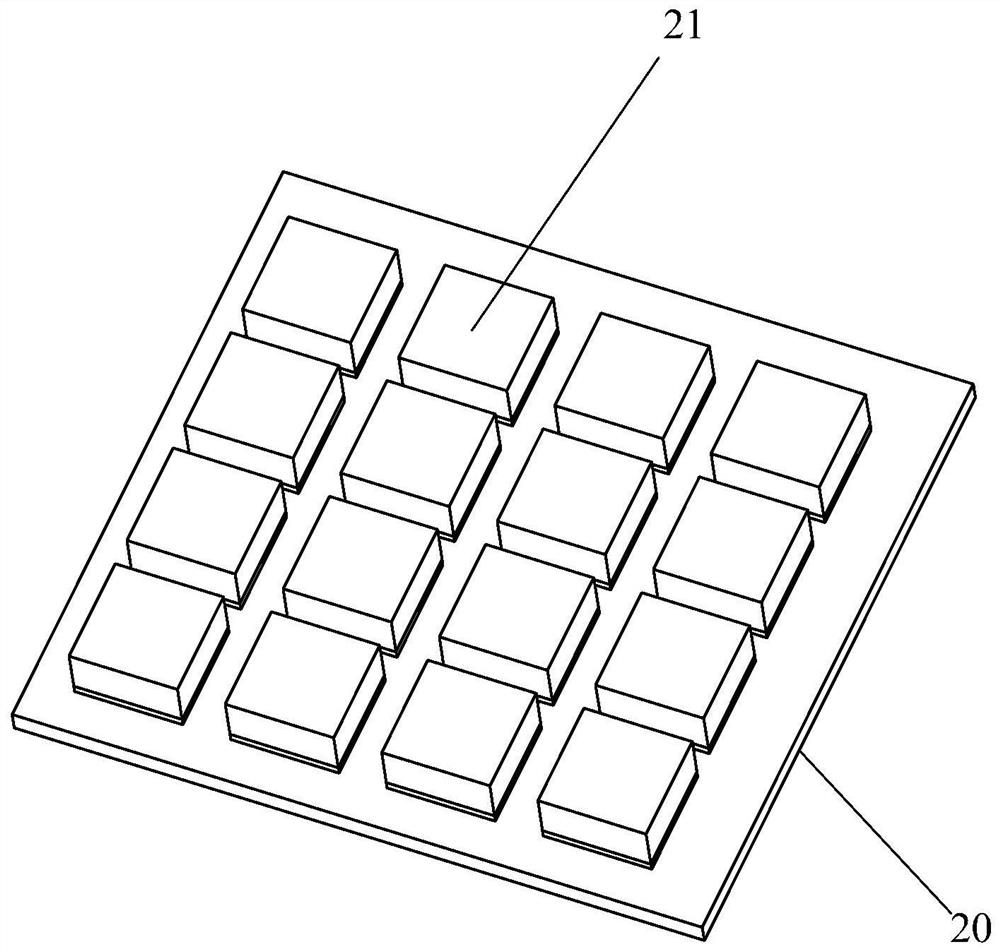

[0043] like figure 1 and figure 2 , this embodiment discloses an LED display module 100 based on an LED light source, which includes a display substrate 1 and an encapsulation module 200 disposed on the display substrate 1, the encapsulation module 200 includes a module substrate 20, several single-pixel packages body 21 and an outer encapsulation layer 22 , the outer encapsulation layer 22 is used to encapsulate several single-pixel encapsulation bodies 21 on the module substrate 20 .

[0044] Please refer to figure 1 , figure 2 , Figure 4 and Figure 5 The single-pixel package 21 includes a unit substrate 210, a plurality of light-emitting chips, and an inner packaging layer 211. The inner packaging layer 211 is used to package a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com