Method for measuring and adjusting axial clearance of thrust bearing of shaft seal type nuclear main pump

A thrust bearing and axial clearance technology, applied in mechanical clearance measurement, measuring device, mechanical measuring device, etc., can solve the problems of inability to check the contact situation, large size of parts, complicated installation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as figure 1 As shown, a method for measuring and adjusting the axial clearance of the thrust bearing of the shaft-sealed nuclear main pump adopts the pressure plate clamping the thrust plate and the dial indicator to measure and accurately measure and adjust the axial clearance of the thrust bearing. The method includes the following steps:

[0032] 1) Complete the pressure plate assembly: place the upper pressure plate 6 on the thrust plate 13, place the mandrel 3 on the upper pressure plate 6, install the lower pressure plate 11 on the thrust plate 13, and use the second hex head bolt 7. Screw through the lower pressure plate 11 and the mandrel 3, place the measuring disc 2 on the mandrel 3, install and tighten the first hex head bolt 1;

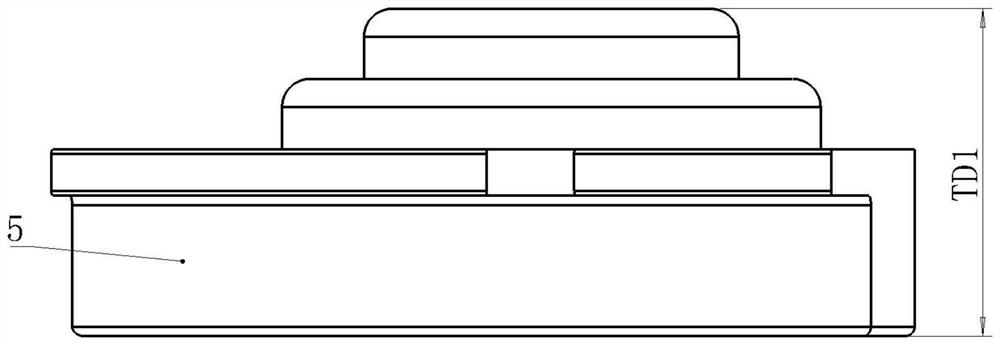

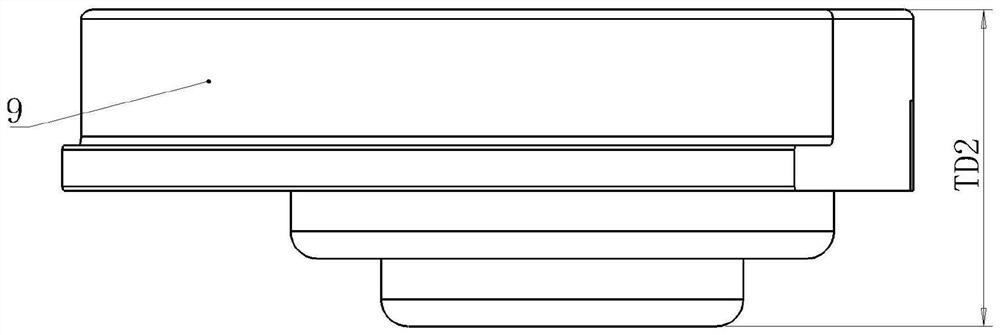

[0033] 2) if figure 2 As shown, measure whether the height TD1 of all main thrust tile assemblies 5 satisfies 69.99mm≤TD1≤70mm, if the height TD1 does not meet the requirements, the existing main thrust tile assemblies 5 shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com