Temperature control device for keeping temperature of industrial furnace

A technology for temperature control devices and industrial furnaces, which is applied to furnaces, furnace components, and electric charge control, etc. It can solve problems such as high furnace body, failure to reach ideal temperature, and inability to save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

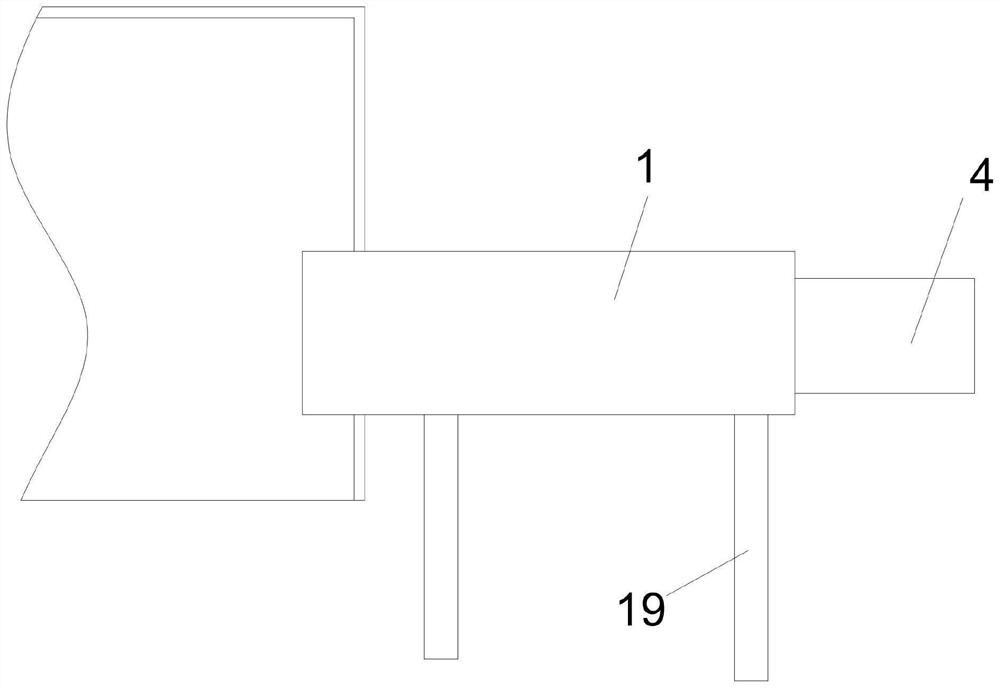

[0033] Please refer to Figure 1-Figure 3 as shown, figure 1 It is a combined structure schematic diagram of the present invention and industrial furnace;

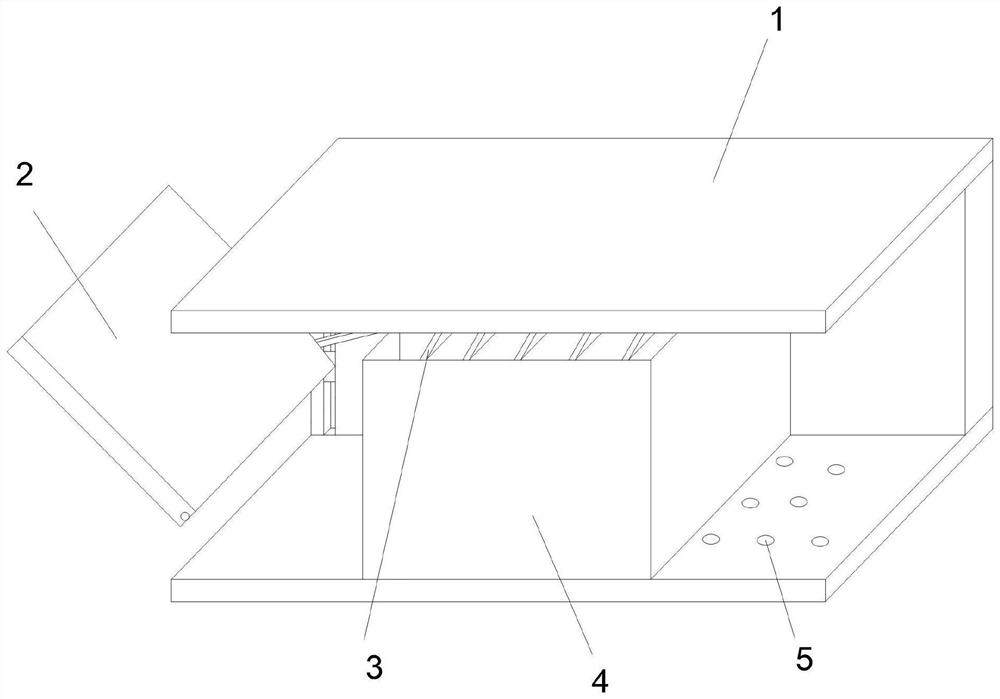

[0034] figure 2 It is a schematic diagram of a partially cut-away three-dimensional structure of the present invention;

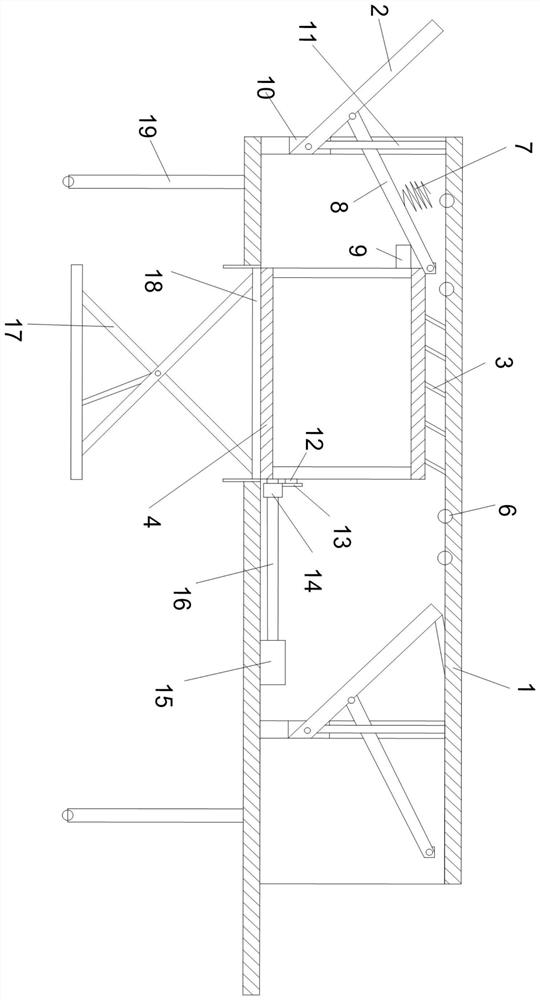

[0035] image 3 It is a cross-sectional combined schematic diagram of the present invention.

[0036]The embodiment of the present application provides a temperature control device for maintaining the temperature of an industrial furnace, including a box body 1 adapted to the furnace mouth of the industrial furnace, and a material box 4 is slid inside the box body 1, and both ends of the material box 4 can be disassembled A material door is provided, and both ends of the box body 1 are provided with a box door assembly for blocking the box body 1, and a drive assembly for driving the material box 4 to move is arranged inside the box body 1. The temperature control device for maintaining the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com