Wire coil for netting machine and netting machine applying wire coil

A net weaving machine and wire reel technology, which is applied in the field of net weaving machines, can solve problems such as high running speed, heavy overall weight, and failure of the net weaving machine to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

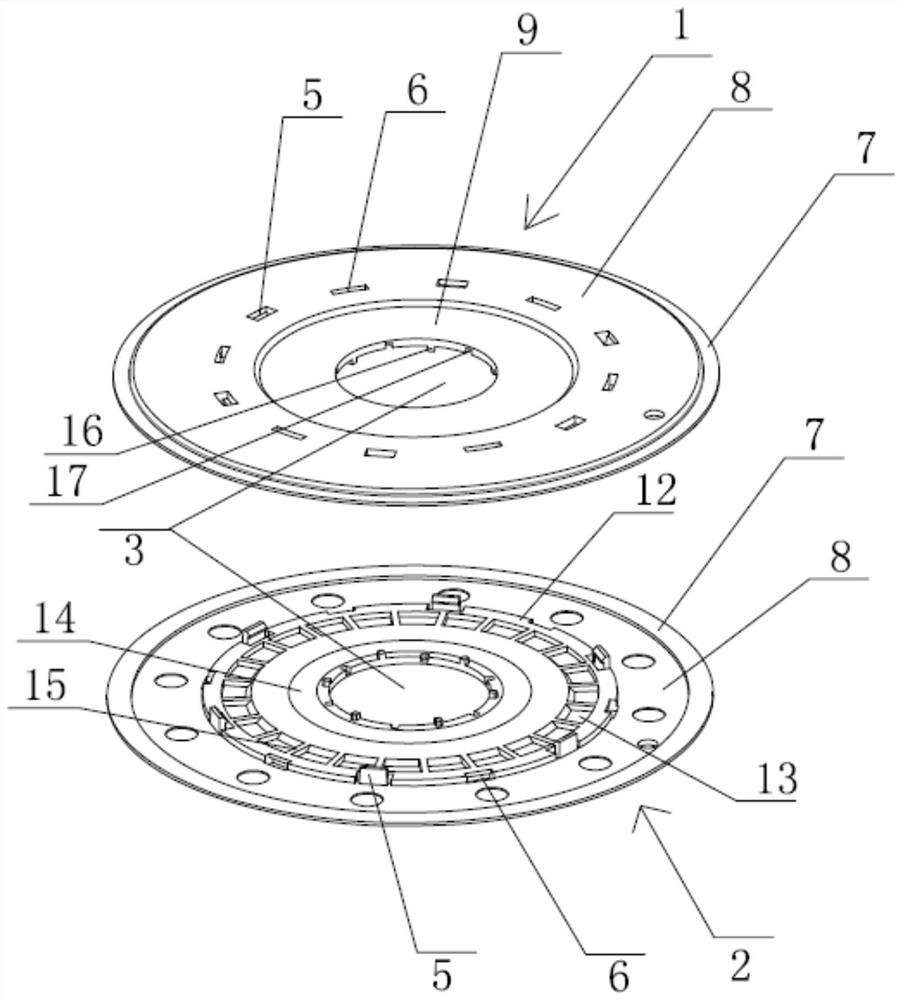

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

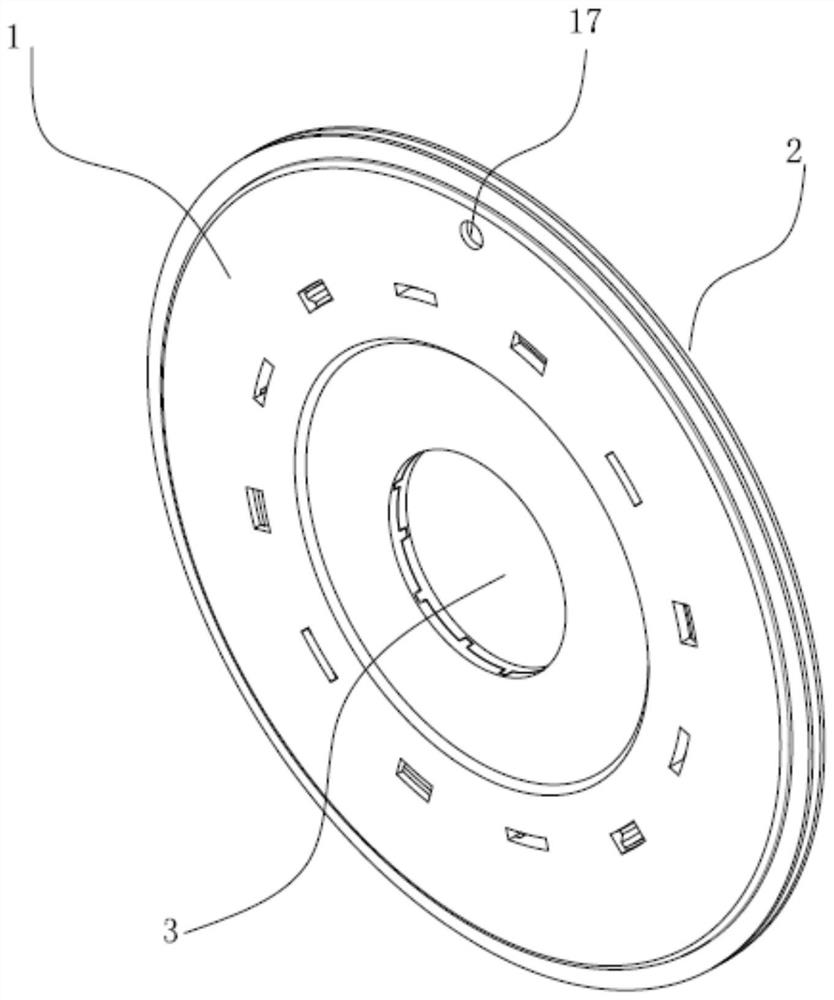

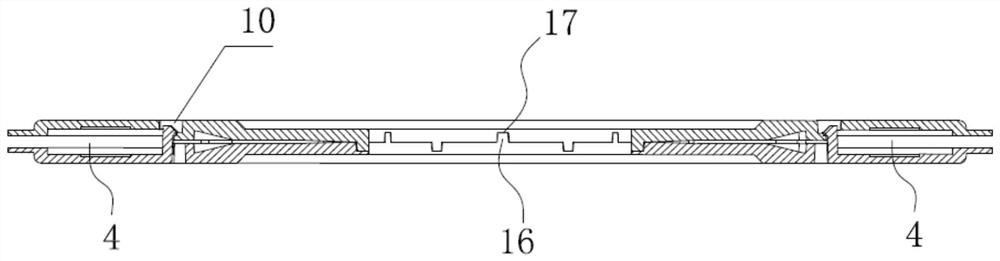

[0021] refer to Figure 1 to Figure 5 , the present invention provides a wire reel for a netting machine, which includes a first sheet 1 and a second sheet 2 oppositely arranged, holes 3 are provided on the first sheet 1 and the second sheet 2, the first Sheet 1 and second sheet 2 are relatively combined to form a wire reel, the first sheet 1 and the second sheet 2 are made of plastic, and the first sheet 1 and the second sheet 2 are combined to form an accommodating space 4. The accommodating space 4 can be used for accommodating the network cables of the weaving net.

[0022] The wire reel made of plastic material will greatly reduce the overall weight, so that more shuttles and wire reels can be set on the net weaving machine to achieve higher weaving efficiency and weave larger nets.

[0023] The first sheet 1 is provided with a plurality of claws 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com