Special fixture for slag stopping cone for manipulator

A special fixture and manipulator technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as high labor intensity, labor occupation, and potential safety hazards, and achieve the effects of improving production efficiency, accurate palletizing positions, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

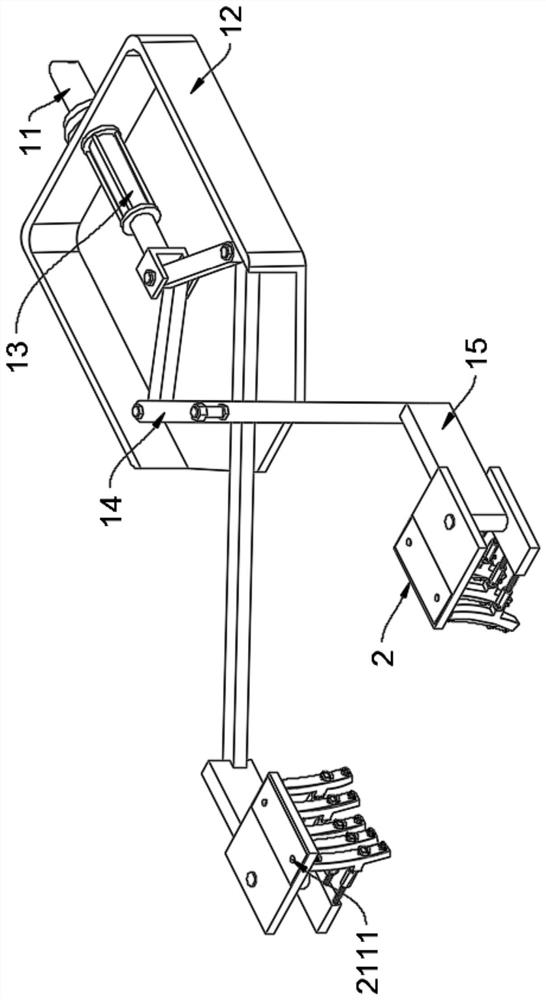

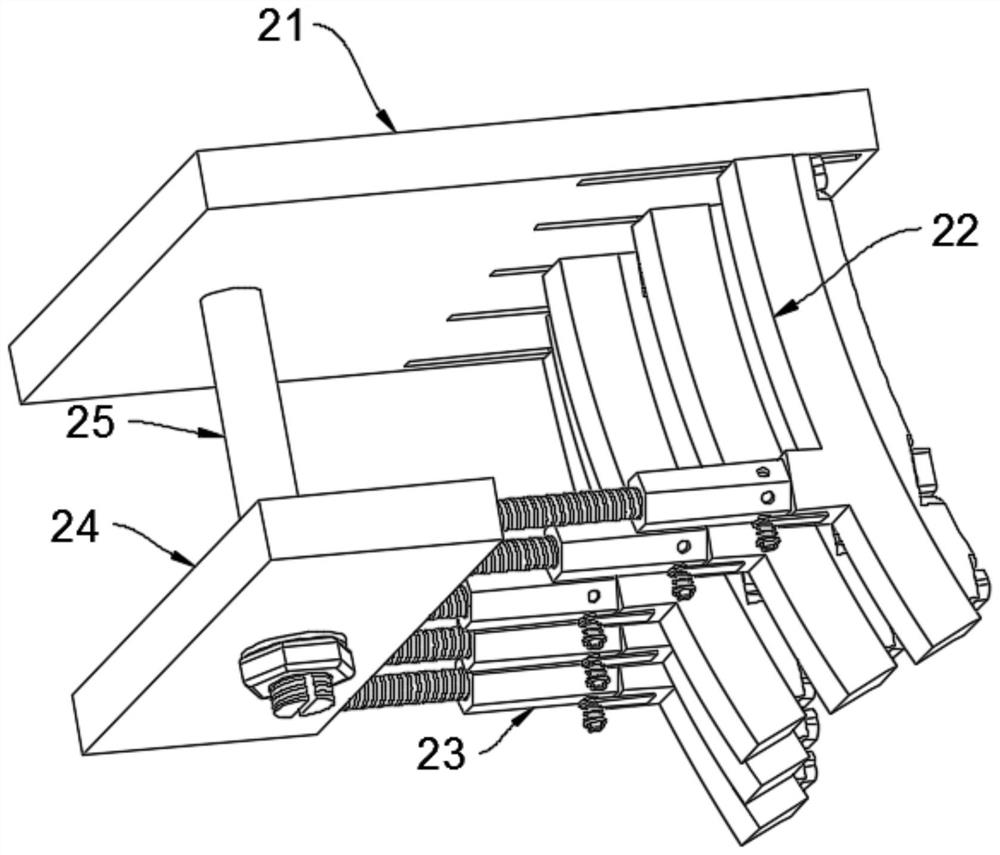

[0028] see Figure 1-9 As shown, a special clamp for slag-stopping cones for a manipulator includes a manipulator 1, and one end of the manipulator 1 is sleeved with a clamp assembly 2, and the clamp assembly 2 consists of a top plate assembly 21, a clip bar assembly 22, a connecting assembly 23, a bottom plate assembly 24 and The pin shaft assembly 25 is composed, and the clip bar assembly 22 is evenly slid and clamped on the lower surface side of the top plate assembly 21. The clip bar assemblies 22 form an arc structure, and the clip bar assembly 22 and the bottom plate assembly 24 pass through the connecting assembly 23 are fixedly connected, and the pin assembly 25 is inserted between the top plate assembly 21 and the bottom plate assembly 24, and the output end of the manipulator 1 is sleeved on the pin assembly 25, the clamp assembly 2 is two groups, and the clamp assembly 2 In a relative structure, the manipulator 1 includes a rotating shaft 11, and the rotating shaft ...

Embodiment 2

[0031] see Figure 1-9 As shown, a special clamp for slag-stopping cones for a manipulator includes a manipulator 1, and one end of the manipulator 1 is sleeved with a clamp assembly 2, and the clamp assembly 2 consists of a top plate assembly 21, a clip bar assembly 22, a connecting assembly 23, a bottom plate assembly 24 and The pin shaft assembly 25 is composed, and the clip bar assembly 22 is evenly slid and clamped on the lower surface side of the top plate assembly 21. The clip bar assemblies 22 form an arc structure, and the clip bar assembly 22 and the bottom plate assembly 24 pass through the connecting assembly 23 are fixedly connected, and the pin assembly 25 is inserted between the top plate assembly 21 and the bottom plate assembly 24, and the output end of the manipulator 1 is sleeved on the pin assembly 25, the clamp assembly 2 is two groups, and the clamp assembly 2 In a relative structure, the manipulator 1 includes a rotating shaft 11, and the rotating shaft ...

Embodiment 3

[0034] see Figure 1-9 As shown, a special clamp for slag-stopping cones for a manipulator includes a manipulator 1, and one end of the manipulator 1 is sleeved with a clamp assembly 2, and the clamp assembly 2 consists of a top plate assembly 21, a clip bar assembly 22, a connecting assembly 23, a bottom plate assembly 24 and The pin shaft assembly 25 is composed, and the clip bar assembly 22 is evenly slid and clamped on the lower surface side of the top plate assembly 21. The clip bar assemblies 22 form an arc structure, and the clip bar assembly 22 and the bottom plate assembly 24 pass through the connecting assembly 23 are fixedly connected, and the pin assembly 25 is inserted between the top plate assembly 21 and the bottom plate assembly 24, and the output end of the manipulator 1 is sleeved on the pin assembly 25, the clamp assembly 2 is two groups, and the clamp assembly 2 In a relative structure, the manipulator 1 includes a rotating shaft 11, and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com