Y/SSZ-13/rare earth/ASA composite material, hydrocracking catalyst, catalyst carrier and preparation method of Y/SSZ-13/rare earth/ASA composite material

A technology of catalyst carrier and composite material, applied in catalyst activation/preparation, catalyst carrier, physical/chemical process catalyst, etc., can solve the problems of low yield of light oil and small catalyst pore volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

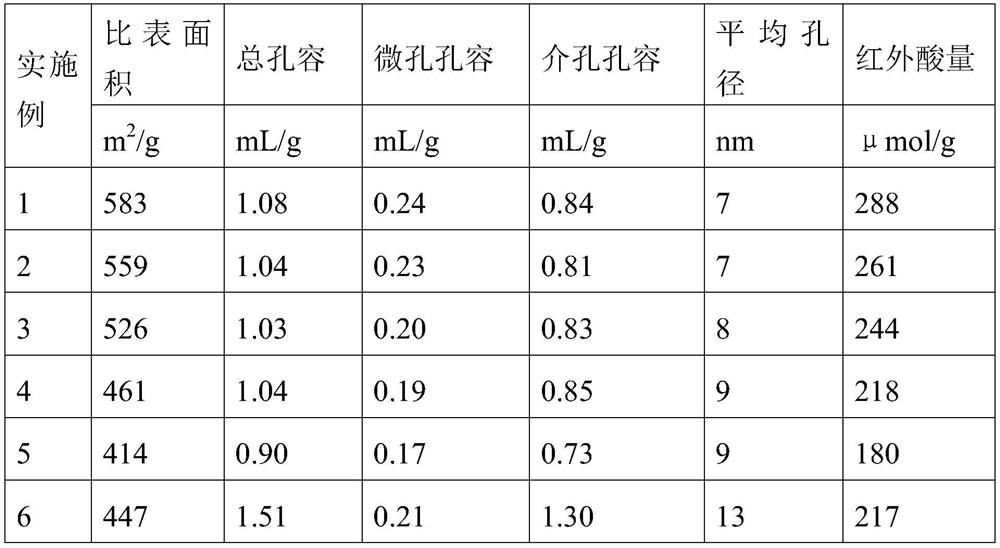

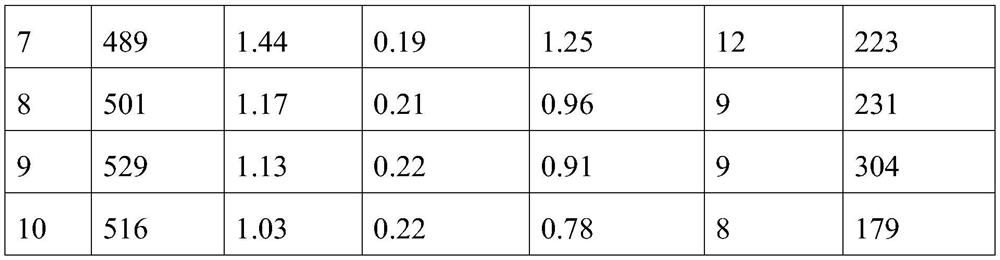

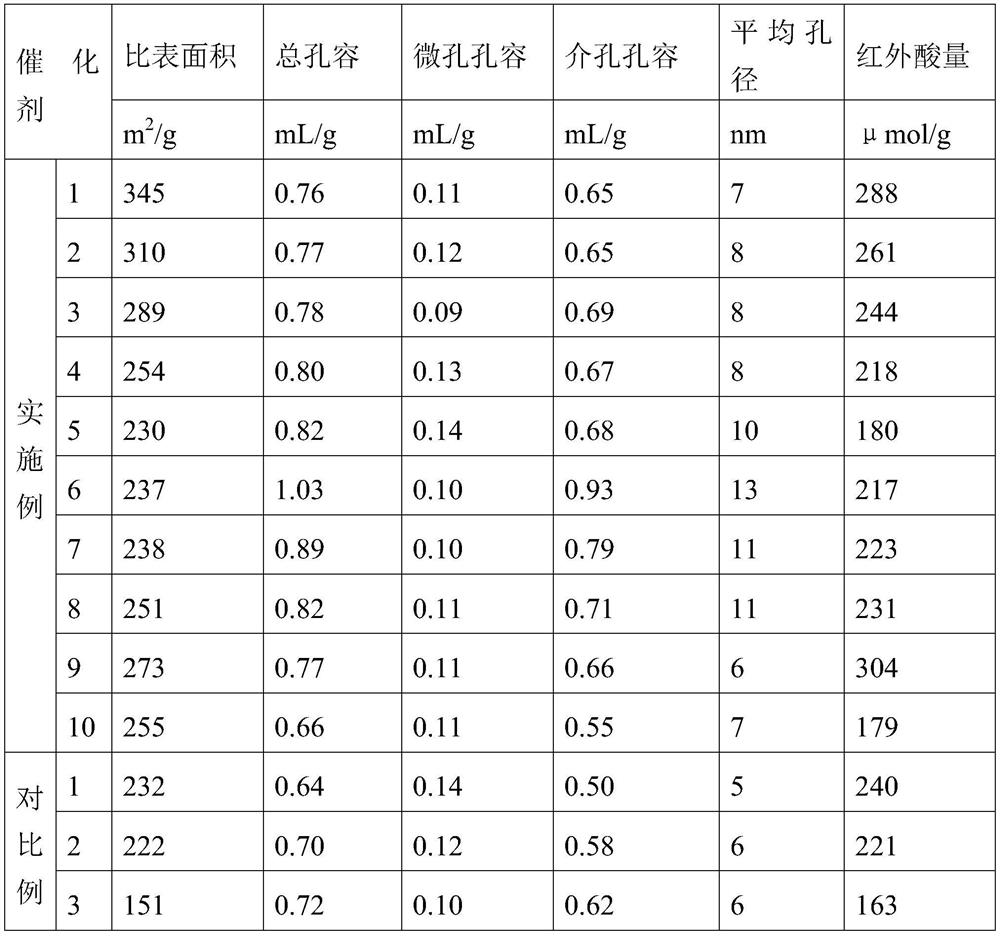

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of Y / SSZ-13 / rare earth / ASA composite material, comprises the steps:

[0034] Step 1, mixing Y molecular sieve, SSZ-13 molecular sieve, aluminum source, basic compound and water, heating and stirring;

[0035] Step 2, adding silicon source and rare earth precursor to the mixture in step 1, heating and stirring to obtain Y / SSZ-13 / rare earth / ASA composite material.

[0036] The invention adopts Y-type molecular sieve, SSZ-13 molecular sieve, rare earth and amorphous silicon-aluminum as the cracking center, and the composite material prepared by step-by-step precipitation method has micropore-mesoporous structure. Among them, although SSZ-13 molecular sieve is a small-pore molecular sieve, it has a significant isomerization function in the cracking reaction of heavy oil molecules, especially in the reaction of diesel hydrocracking to produce jet fuel. The combination of SSZ-13 molecular sieve and Y-type molecular sieve, r...

Embodiment 1

[0052] (1) According to the amount that the total weight of molecular sieve accounts for 50wt% of the weight of the composite material, weigh 19g of Y-type molecular sieve with a silicon-aluminum ratio of 7.5 and 1g of SSZ-13 with a silicon-aluminum ratio of 20 and add them to the reactor.

[0053] (2) The solid aluminum sulfate is prepared into 500mL concentration of 20g Al 2 o 3The aluminum sulfate solution (A) of / L is added the dilute ammonia solution (B) of 10wt% by adding an amount of deionized water to the strong ammonia water, gets the concentrated water glass solution and adds an amount of deionized water and is diluted into the water glass solution of 72mL 14wt% ( C). Take 2g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), join in 10mL water, obtain CeO 2 Solution (D) with a content of 6.61%.

[0054] (3) Add 100mL deionized water to the reaction kettle and heat it to 75°C, add (A) and (B) to make the mixed slurry gel for 60min under the condition of pH 8.0, after the fe...

Embodiment 2

[0062] (1) According to the addition of 50 wt% of the total weight of the molecular sieve to the weight of the composite material, 14g of Y-type molecular sieve with a silicon-aluminum ratio of 10 and 6g of SSZ-13 molecular sieve with a silicon-aluminum ratio of 50 were weighed and added to the reactor.

[0063] (2) The solid aluminum sulfate is prepared into 500mL concentration of 20g Al 2 o 3 The aluminum sulfate solution (A) of / L is added the dilute ammonia solution (B) of 10wt% by adding an amount of deionized water to the strong ammonia water, gets the concentrated water glass solution and adds an amount of deionized water and is diluted into the water glass solution of 72mL 14wt% ( C). Take 2g of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), was added to 10mL water to obtain La 2 o 3 Solution (D) with a content of 3.76%.

[0064] (3) Add 100mL deionized water to the reaction kettle and heat it to 75°C, add (A) and (B) to make the mixed slurry pH 8.5 and carry out gela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com