Method for breaking composite material

A technology of composite materials and brittle materials, applied in the field of splitting composite materials, can solve problems such as difficulty and degradation of end face quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] In Example 1, first, a polyvinyl alcohol-based film was dyed with a dichroic substance such as iodine or a dichroic dye, and uniaxially stretched to obtain a polarizer. The thickness of the polarizer was 28 μm.

[0140] Next, an acrylic protective film (thickness: 40 μm) was bonded to one surface of the polarizer, and a cellulose triacetate protective film (thickness: 30 μm) was bonded to the other surface to obtain a polarizing film 21 . Then, a polyethylene terephthalate release film (thickness: 38 μm) as a release liner 23 was bonded to the polarizing film 21 via an acrylic adhesive (thickness: 30 μm) as an adhesive 22, The main body of the resin layer 2 was obtained.

[0141] On the other hand, as the brittle material layer 1 , a glass film (manufactured by NEC Glass Co., Ltd., trade name "OA-10G", thickness: 100 μm) was prepared.

[0142] In addition, as the adhesive 24, 70 parts by weight of CELLOXIDE 2021P (manufactured by Daicel Chemical Industry Co., Ltd.), 5...

Embodiment 2

[0148]

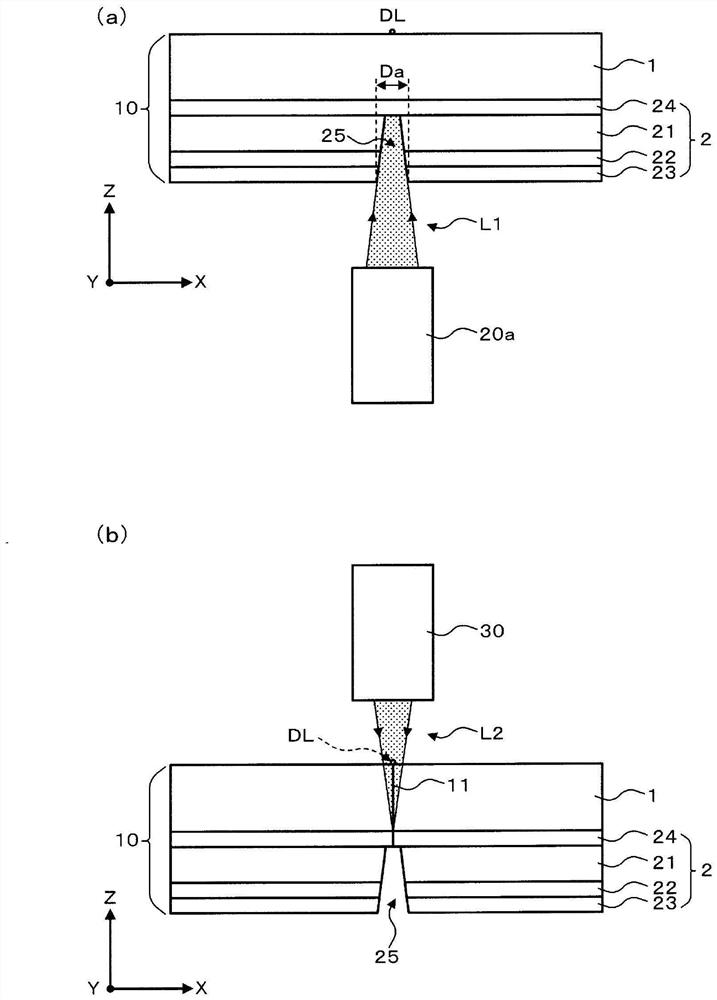

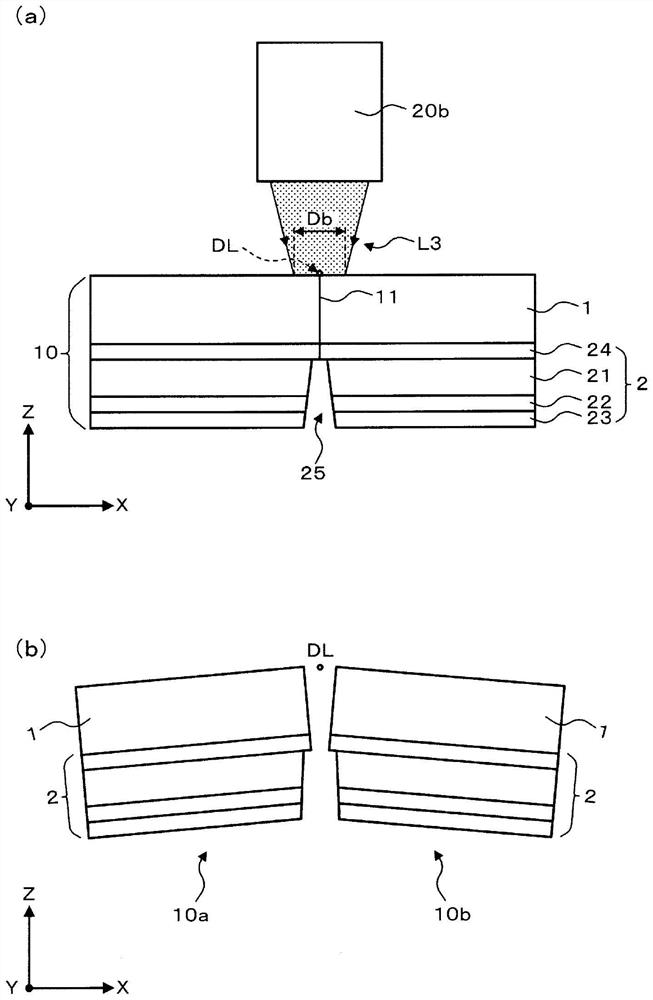

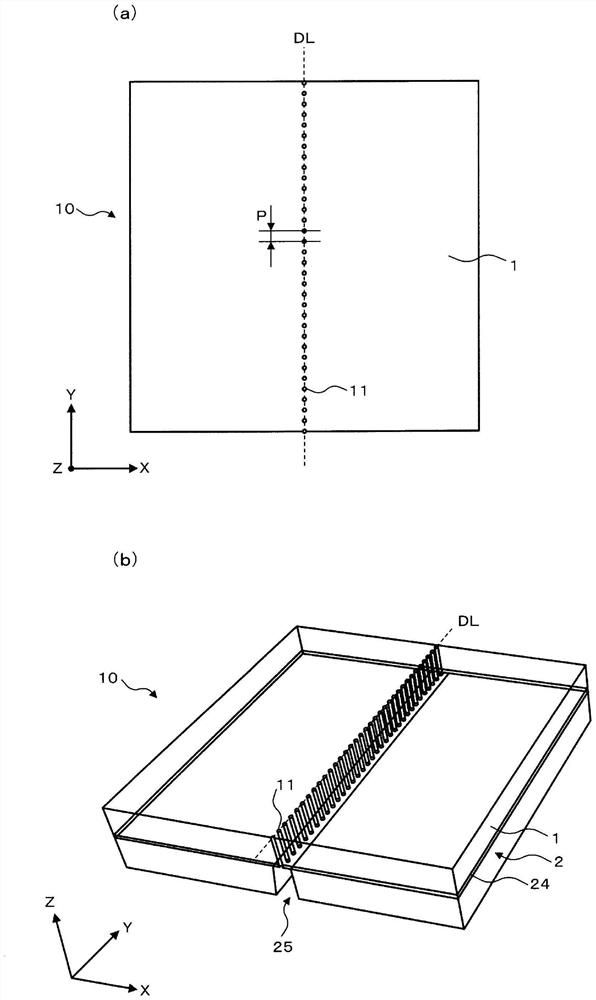

[0149] In Examples 2-11, such as Figure 4 As shown, at least one of the output of the second laser light source 20b, the spot diameter Db of the laser light L3, and the relative moving speed of the laser light L3 is set to be different from that of Embodiment 1, and under other conditions identical to that of Embodiment 1, the Composite 10 breaks.

[0150]

[0151] In the reference example, the brittle material layer 1 was irradiated with laser light L3 oscillated by the second laser light source 20 b from the resin layer 2 side, and the composite material 10 was divided under the same conditions as in Example 1.

[0152]

[0153] The presence or absence of cracks was evaluated by visually observing the end faces of the brittle material layer 1 of the composite material 10 (composite material sheet) split by the splitting method of Examples 1 to 11 and the reference example.

[0154] Figure 4 "A" and "B" described in the column of "fracture state of brittle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com