Loudspeaker module

A speaker mold and module technology, applied in the electronic field, can solve problems such as product quality impact, glue overflow, air leakage, etc., and achieve the effects of improving product yield and processing efficiency, reducing production costs, and simplifying cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

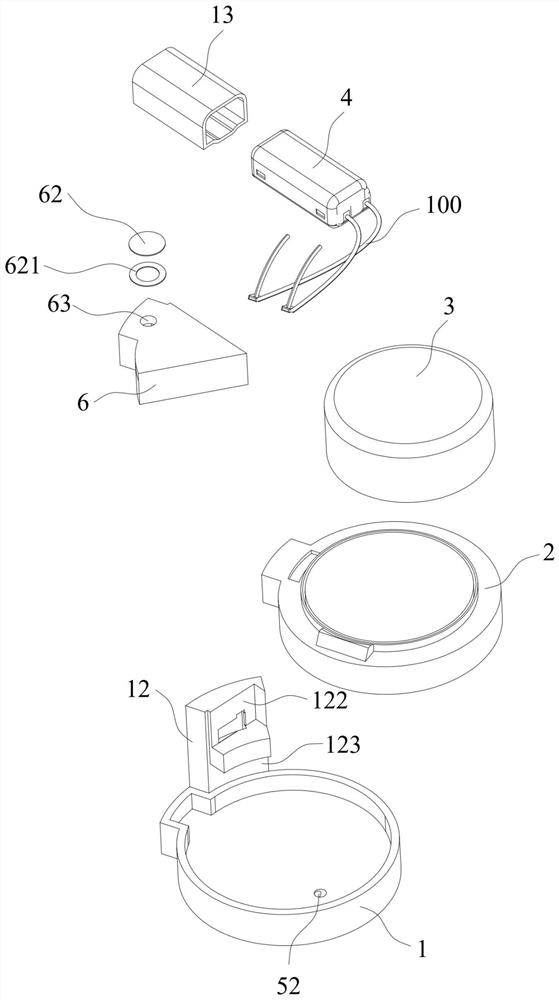

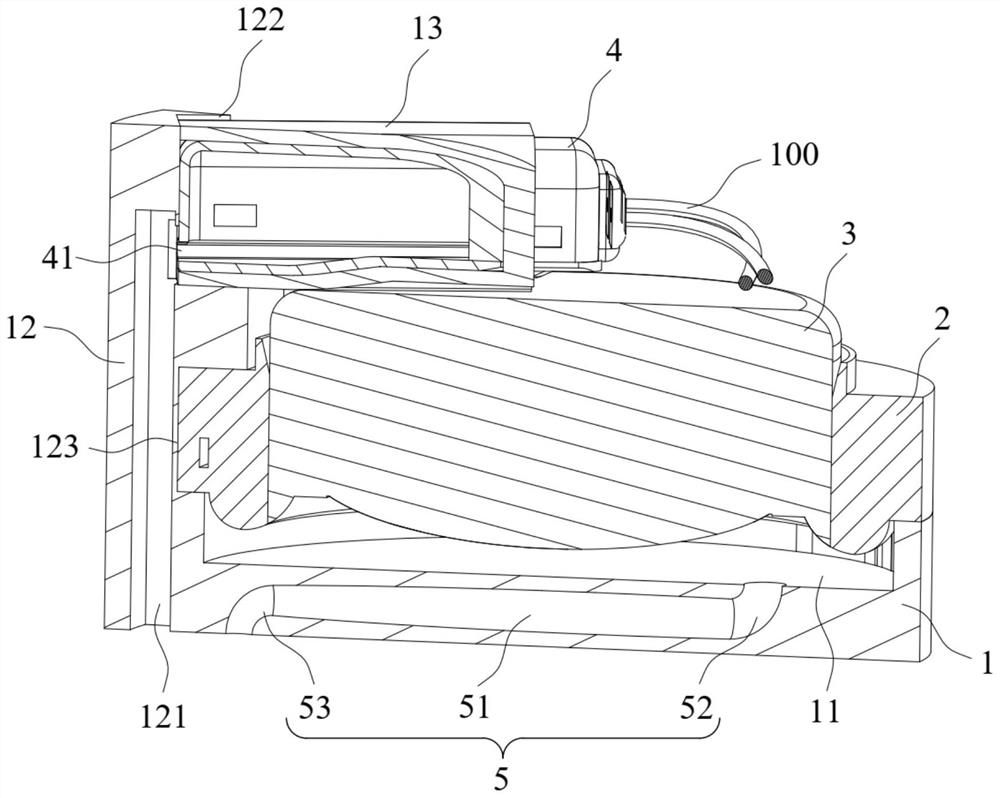

[0045] see Figure 1 to Figure 3 , this embodiment provides a speaker module, including a module case 1, a first shock absorber 2, a first speaker 3 and a first sound outlet pipe 5, and a front cavity 11 is opened on the surface of the module case 1; The first shock absorber 2 is arranged on the end face of the module housing 1 facing the front cavity 11; the first horn 3 is arranged on the first shock absorber 2, and the first horn 3 corresponds to the front cavity 11; the second The horn 4 is arranged on the module housing 1, and the sound outlet 41 of the second horn 4 is connected to the outer surface of the module housing 1 and communicates with the second sound outlet duct 121 of the module housing 1; the first sound outlet duct 5 Set in the module housing 1, one end communicates with the front cavity 11, and the other end communicates with the surface of the module housing 1 away from the front cavity 11, such as the side of the module housing 1 or the side facing away ...

Embodiment 2

[0064] This embodiment provides a speaker module, which includes a module housing 1 , a first shock absorber 2 , a first speaker 3 , a second speaker 4 , a first sound outlet pipe 5 and a rear cover 6 . The difference between this embodiment and the first embodiment is: see Figure 6 and Figure 7 , the first horn 3, the first shock absorber 2 and the rear cover 6 in this embodiment jointly define the rear cavity 61, and the first horn 3, the first shock absorber 2 and the module housing 1 jointly define the front cavity 11. The first shock absorber 2 is provided with a through hole 21, and the through hole 21 communicates with the rear cavity 61 and the front cavity 11 respectively. At this time, the rear cavity 61 can communicate with the front cavity 11, which can reduce the risk of getting close to the through hole. The binding force received by the first shock absorber 2 in part 21 improves the shock absorption effect.

[0065] see Figure 6 and Figure 7 , the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com