A kind of method for replenishing lithium of lithium ion battery

A technology for lithium-ion batteries and lithium supplementation, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., and can solve the problem of lithium-complementing material negative electrode decomposing lithium, too little lithium-complementing material, and the expected effect cannot be achieved and other problems, to achieve the effect of increasing the amount of addition, overcoming lithium precipitation at the negative electrode, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

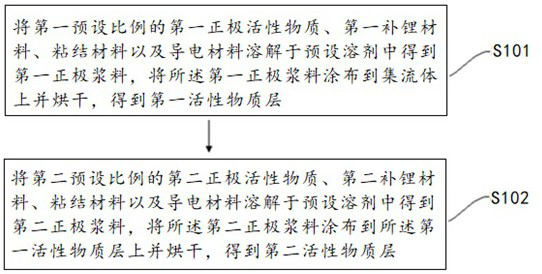

[0085] figure 2 It is a flow chart of the preparation method of the positive electrode of the lithium ion battery provided by the embodiment of the present application, referring to figure 2 As shown, the embodiment of the present application also provides a method for preparing the positive electrode of the above-mentioned lithium ion battery, the preparation method comprising:

[0086] S101: Dissolving the first positive electrode active material, the first lithium-supplementing material, the binding material, and the conductive material in the first predetermined proportion in a predetermined solvent to obtain a first positive electrode slurry, and coating the first positive electrode slurry onto the current collector and dried to obtain the first active material layer;

[0087] S102: Dissolving the second positive electrode active material, the second lithium-supplementing material, the binding material, and the conductive material in a preset solvent in a second predet...

Embodiment 1

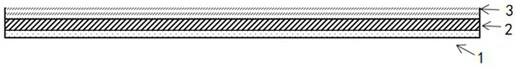

[0114] An embodiment of the present application provides a lithium-ion battery, which includes a negative electrode, a diaphragm stack, and a positive electrode of a lithium-ion battery, wherein the positive electrode of a lithium-ion battery includes a current collector and an active material layer disposed on the surface of the current collector, and the active material layer includes at least The first active material layer in contact with the surface of the current collector and the second active material layer arranged on the surface of the first active material layer, the first active material layer contains a first lithium supplementary material, and the second active material layer contains a second supplementary lithium material. For the lithium material, the decomposition voltage of the first lithium supplementary material in the first active material layer is lower than the decomposition voltage of the second lithium supplementary material in the second active materia...

Embodiment 2

[0127] The difference from Example 1 is that the preparation process of the lithium-ion battery is as follows:

[0128] The NCM811, , PVDF and SUPER-P are proportioned according to the mass ratio of 92:3:2:3, dissolved in NMP to obtain the first positive electrode slurry, and the first positive electrode slurry is coated on the aluminum foil and dried to obtain a first active material layer;

[0129] Will , , PVDF and SUPER-P are proportioned according to the mass ratio of 89:7:2:2, dissolved in NMP to obtain the second positive electrode slurry, and the second positive electrode slurry is coated on the first active material layer, Drying to obtain the positive electrode sheet of the lithium-ion battery;

[0130] Dissolving graphite, (CMC+SBR) and super-P in NMP at a ratio of 95:2:3 to obtain negative electrode slurry, coating the negative electrode slurry on copper foil, and drying to obtain negative electrode sheet;

[0131] The positive electrode sheet, the negative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com