Irrigation area channel flow measurement method based on gradient effect of semi-cylindrical rectangular grooves on two sides

A rectangular trough and semi-cylindrical technology, applied in the field of canal flow measurement in irrigation areas, can solve the problems of long time-consuming, poor prediction flow accuracy, and inability to predict the flow rate of the central cylindrical rectangular trough, so as to improve utilization efficiency and avoid backwater Waste, the effect of improving numerical calculation accuracy and calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

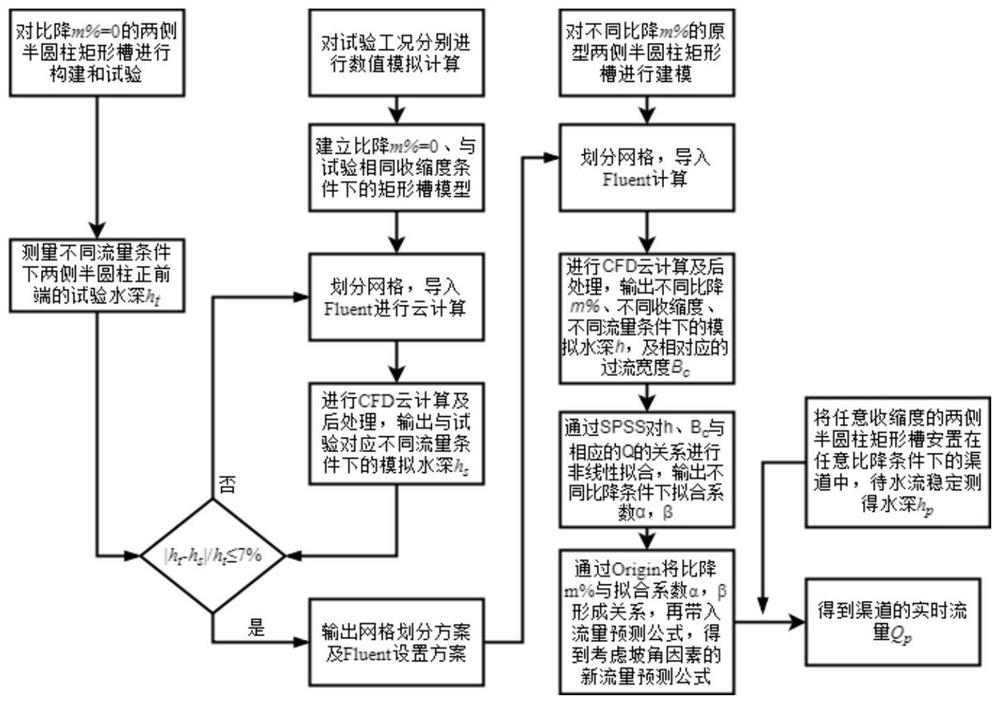

[0047] The flow chart of the method for predicting the channel flow of the irrigation area through a semi-cylindrical rectangular groove on both sides of this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0048] Step 1: Establish a physical test model of a semi-cylindrical rectangular groove on both sides and conduct a physical model test. When the water flow is stable, collect the height of the submerged water depth at the front end of the semi-cylindrical;

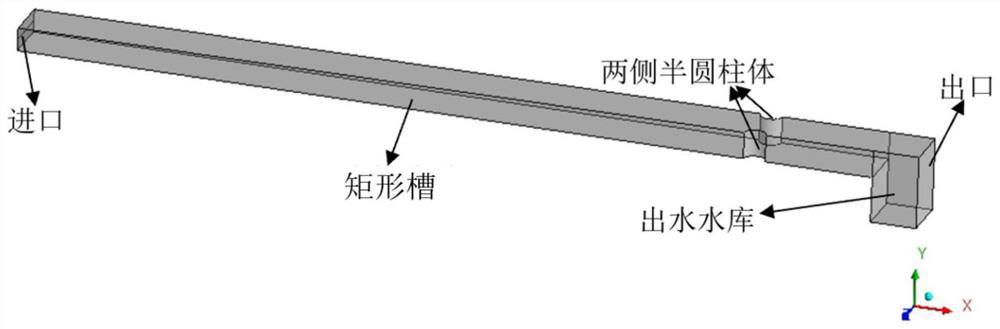

[0049] In the physical model, the material of the semi-cylindrical rectangular trough model on both sides is made of transparent plexiglass, the bottom of the rectangular trough is placed horizontally, the rectangular trough is provided with an inlet and an outlet, and there are half cylinders on both sides of the rectangular trough near the rectangular trough exit. A liftable device is installed under the entrance, and the exit is hinged on the bracket. The cross-section of the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com