Numerical design method of adiabatic mode coupler

A mode coupling and design method technology, applied in the direction of instruments, optical components, optics, etc., can solve the problems of complex structure and difficult processing, and achieve the effect of simple structure, speed up and saving computing memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

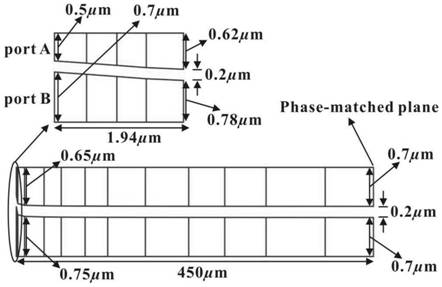

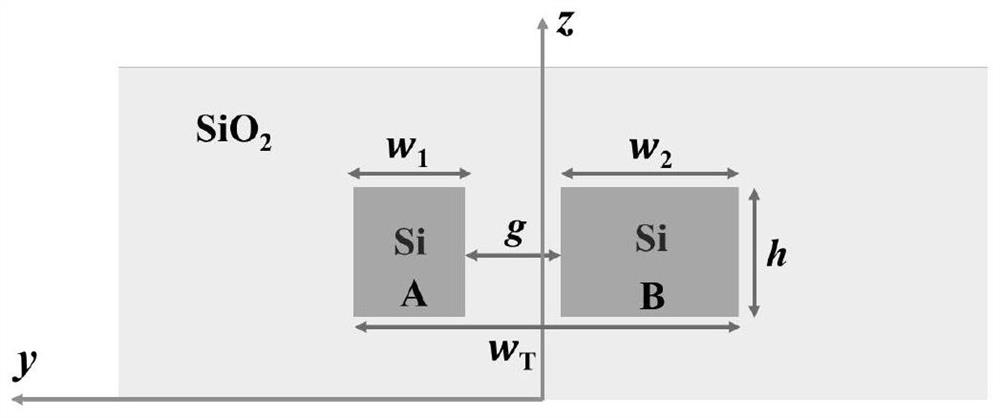

[0025] The present invention illustrates the design process by using an adiabatic mode coupler fabricated on a silicon waveguide plate on a silicon thin film substrate. A schematic diagram of an adiabatic mode coupler is shown in figure 1 and 2 As shown, it involves two waveguides, waveguide A and waveguide B placed next to each other. The cross-section of an adiabatic mode coupler as figure 1 Shown, where the height of the silicon waveguide h = 0.3μm. The widths of the two silicon waveguides are denoted as w 1 and w 2 , the gap width between the waveguides is marked g, and the optical wavelength is 1.55 μm.

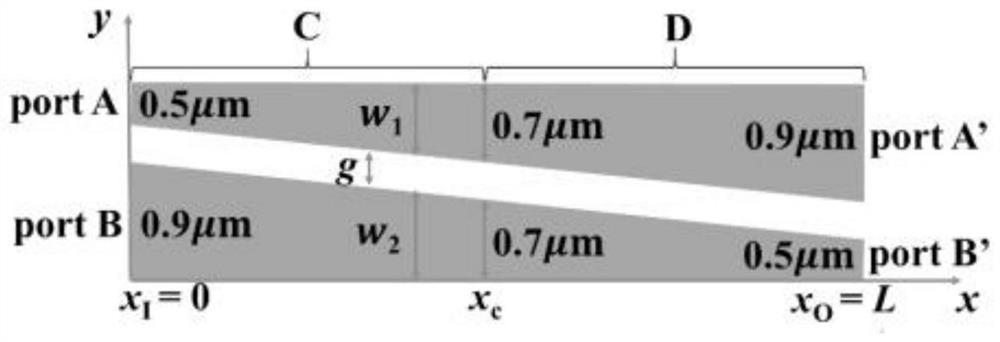

[0026] Such as figure 2 As shown, the width w of the two waveguides 1 and w 2 gradually changes along the propagation direction x, at one end of the coupler, that is, the input plane x = x I = 0, the waveguide of one silicon waveguide is narrower and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com