Screening equipment provided with flatness detection mechanism and used for electronic product production

A technology for testing mechanisms and electronic products, applied in electrical/magnetic roughness/irregularity measurement, electromagnetic measurement devices, etc., can solve the problems of low accuracy, low detection efficiency, long detection process, etc., to improve detection accuracy , The effect of high degree of automation and improved detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

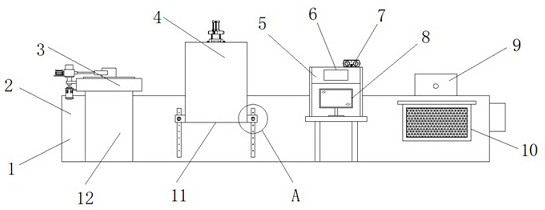

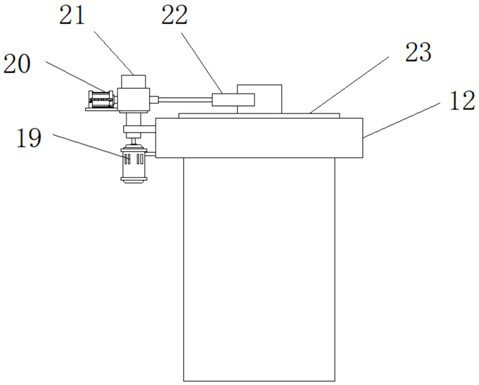

[0026] Example 1: See Figure 1-6 , a screening device for electronic product production with a flatness detection mechanism, comprising a transmission unit 1 and a detection unit 4, the detection unit 4 is provided in the middle section of the transmission unit 1, and a feeding unit 3 is provided at one end of the transmission unit 1 , the other side of the loading unit 3 is provided with a control unit 5, and the other side of the transmission unit 1 is provided with a blanking unit 9, the transmission unit 1 includes a detection platform 2, and the top of the detection platform 2 is provided with an electric slide rail 25, and the electric The end of the slide rail 25 is provided with a limit block 24, and the outside of the top of the electric slide rail 25 is provided with a moving seat 30, and one side of the top of the moving seat 30 is provided with a clamping cylinder 31;

[0027] The output end of the clamping cylinder 31 is fixedly connected with a splint 32 through...

Embodiment 2

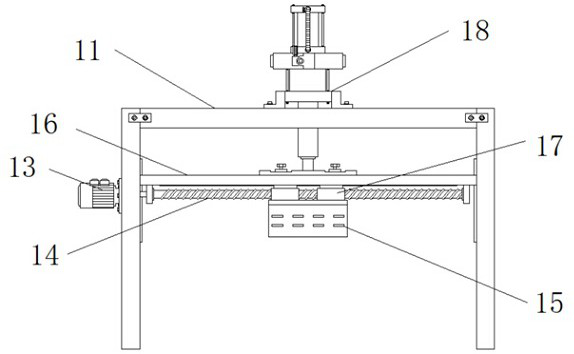

[0029] Embodiment 2: a hydraulic cylinder 18 is installed on the top of the installation frame 11, the output end of the hydraulic cylinder 18 is fixedly connected with a fixed plate 16 through a piston rod, the bottom end of the fixed plate 16 is movably connected with a threaded rod 14, and the other end of the installation frame 11 A detection motor 13 is fixedly connected, and the output end of the detection motor 13 is fixedly connected with the threaded rod 14 through a coupling. The external movable part of the threaded rod 14 is connected with a threaded block 17, and the top end of the threaded block 17 is embedded in the reserved part of the fixed plate 16. Sliding in the groove, the bottom end of the threaded block 17 is fixedly connected with the detection head 15;

[0030] Specifically, such as figure 1 , figure 2 , Figure 4 and Figure 6 As shown, the detection unit 4 uses the CDD visual inspection system to quickly scan and detect the flatness of the produc...

Embodiment 3

[0031]Embodiment 3: The detection unit 4 includes an adjustable fixing part 34, and the adjustable fixing part 34 is fixedly connected to both ends of the testing table 2, and the testing table 2 is equipped with a mounting frame 11 through the adjustable fixing part 34;

[0032] Specifically, such as figure 1 , figure 2 and Figure 6 As shown, the installation frame 11 is installed in the middle section of the detection table 2, and is fixedly connected by the adjustable fixing part 34, which can be quickly disassembled and adjusted through the installation hole of the adjustable fixing part 34 to adjust the overall erection height, so as to be suitable for products of different sizes. Detection, compared with one-piece installation, has stronger maintainability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com