Harmonic reducer and robot

A technology of harmonic reducer and input shaft, which is applied in the direction of manipulators, mechanical equipment, program control manipulators, etc. It can solve the problem that the small diameter of the hollow hole cannot meet the needs of a large number of cables, and achieve the effect of compact bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

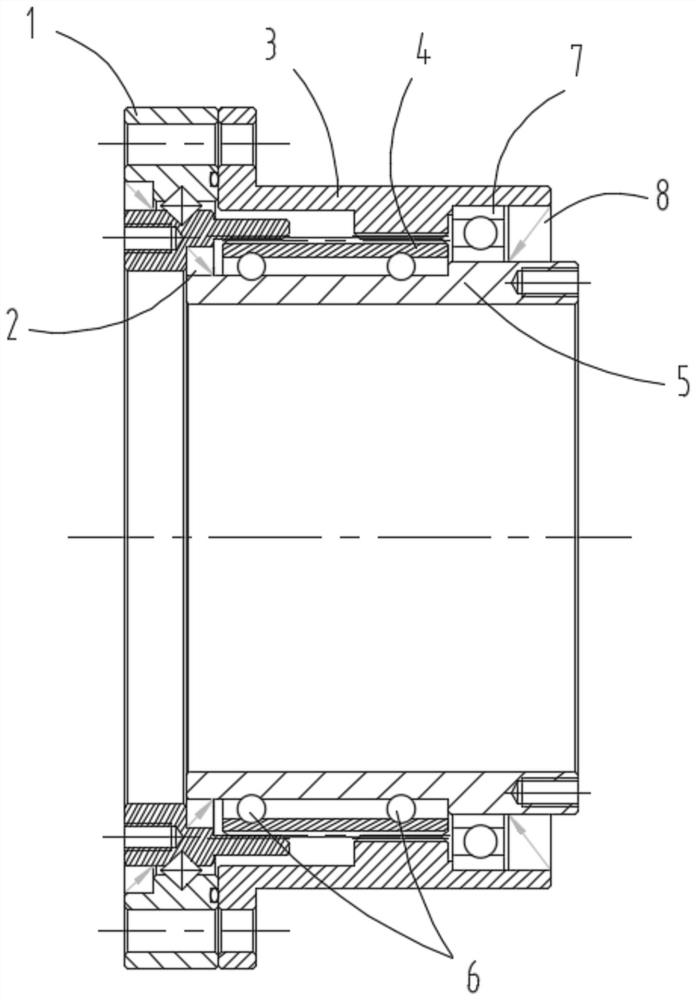

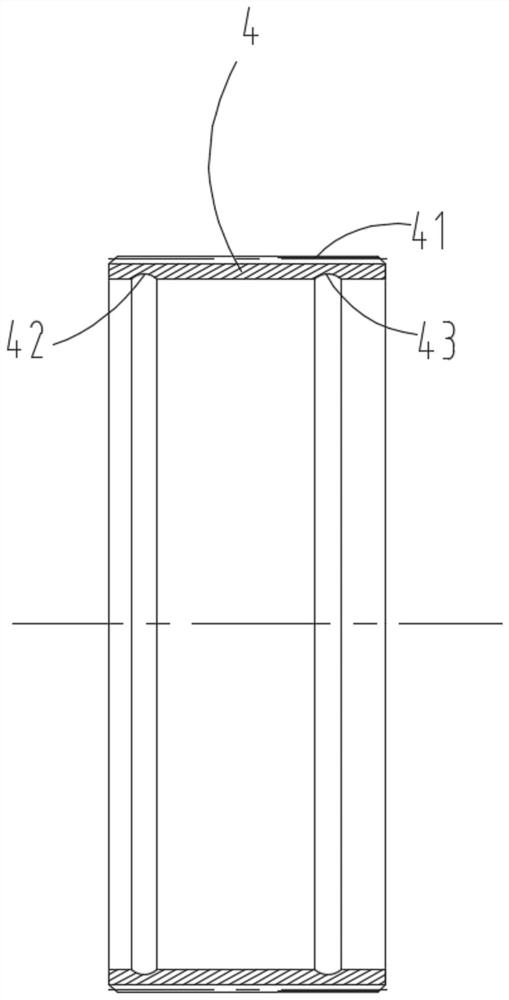

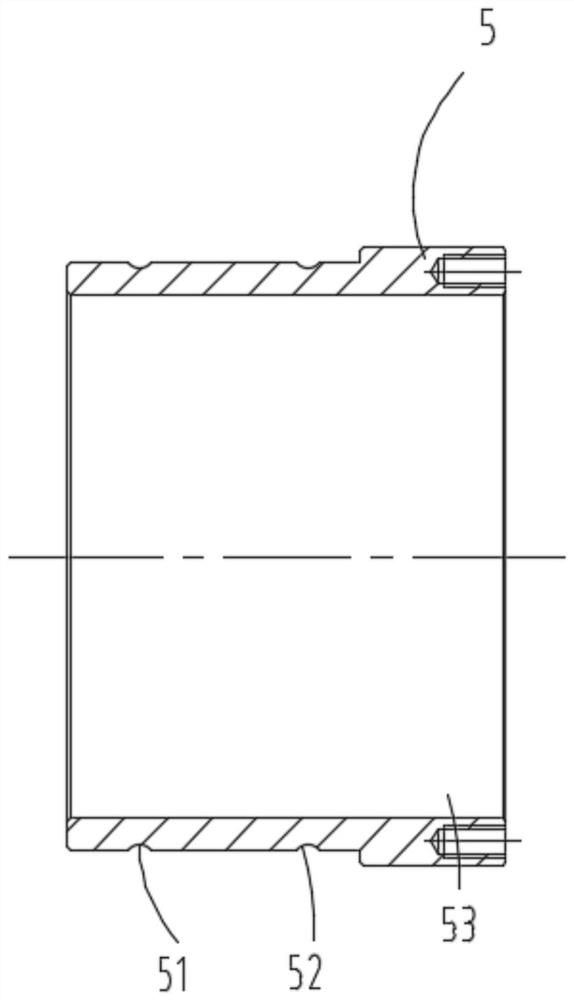

[0021] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, a harmonic reducer is provided, including an input shaft 5 and a flex spline 4, the input shaft 5 has a hollow hole 53 passing through both axial ends thereof, the input shaft 5 and the The flexible spline 4 is set and a gap is formed between the two. A first raceway 52 is provided on the outside of the shaft wall of the input shaft 5, and a second roller is provided on the side of the flexspline 4 facing the input shaft 5. The track 43, the ball 6 is arranged between the first track 52 and the second track 43. In this technical solution, the outer ring and the inner ring of the bearing between the input shaft and the flexspline in the traditional harmonic reducer are respectively integrated with the flexspline 4 and the input shaft 5 to replace it, so that the bearing structure is compact, Furthermore, the diameter of the hollow hole 53 of the input shaft 5 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com