Working method of overlapped elephant trunk device

A working method and technology of sliding pipes, which can be used in infrastructure engineering, construction, etc., can solve the problems of affecting the flatness of the crushed stone cushion, difficult for crushed stones to pass through the riprap pipe, and large bending range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

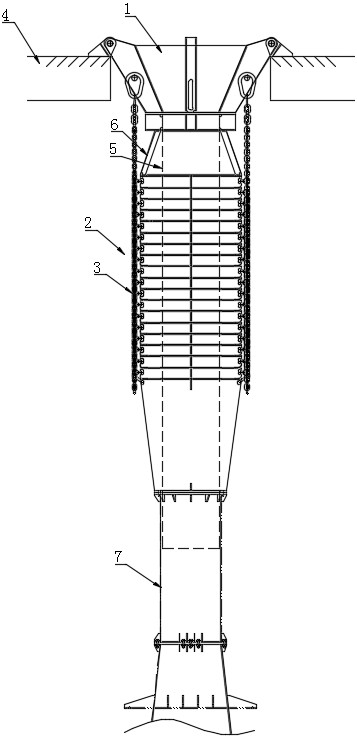

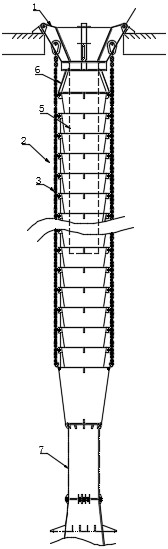

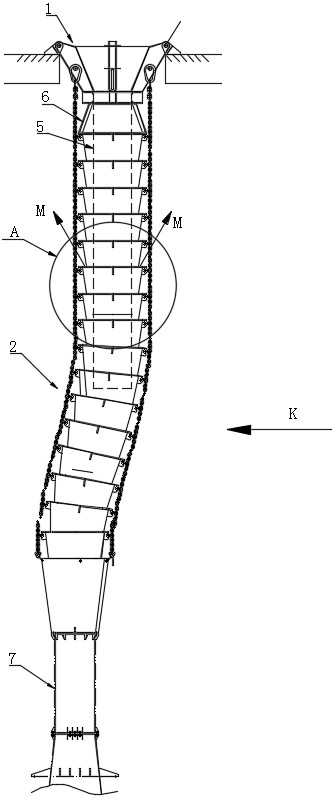

[0031] like Figure 1-Figure 5 As shown, a stacked pipe slide device is used for leveling the ship for gravel riprap operations. The pipe slide device is arranged on the hull 4 and hoisted by a crane. The pipe slide device includes a lower hopper 1 , the cone barrel body 2 and more than two chains 3 for hoisting the cone barrel body 2; the lower hopper 1 is installed on one side of the hull 4, one end of the chain 3 is connected with the lower hopper 1, and the other end of the chain 3 One end is movably connected with the end of the cone body 2 away from the lower hopper 1 .

[0032] The upper and lower sides of the lower hopper 1 are respectively provided with a feed port and a discharge port, and the discharge port of the lower hopper 1 is connected with a rigid guide pipe 5 and a guide device 6, and the diameter of the guide devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com