Machining equipment for punching arc workpiece and using method of machining equipment

A technology for processing equipment and workpieces, which is applied in the field of processing equipment for punching circular arc workpieces, can solve the problems of unsatisfactory punching methods, low punching efficiency, and difficulty in ensuring punching quality, and achieve large-scale punching production operations , realize the ideal and ingenious effect of automatic control and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

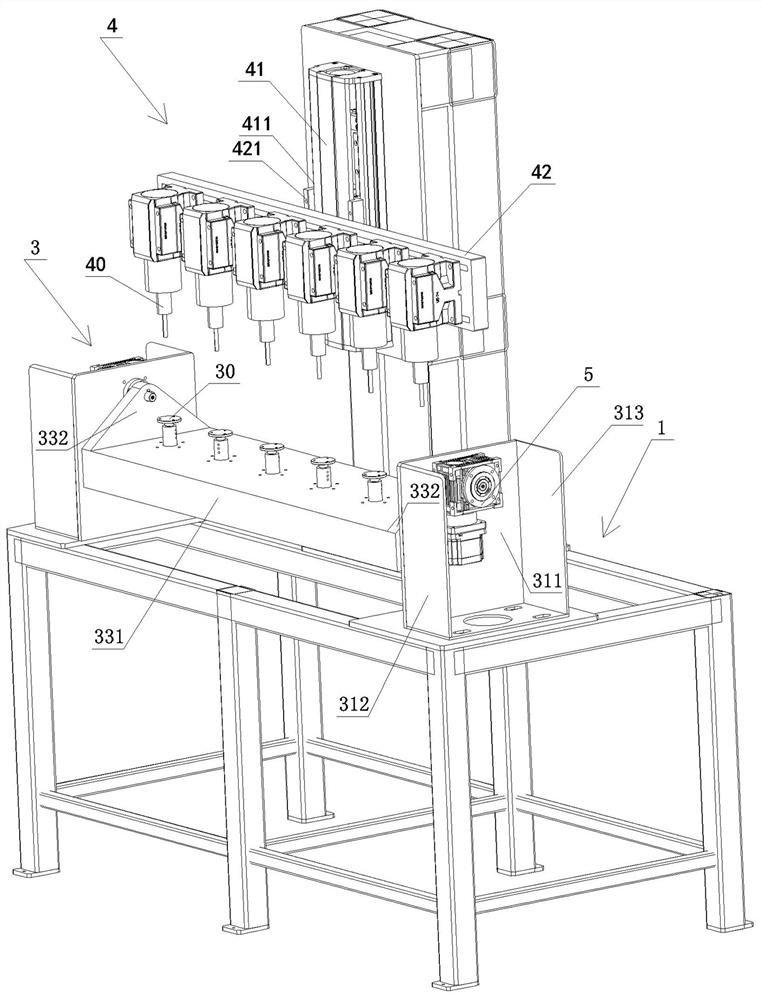

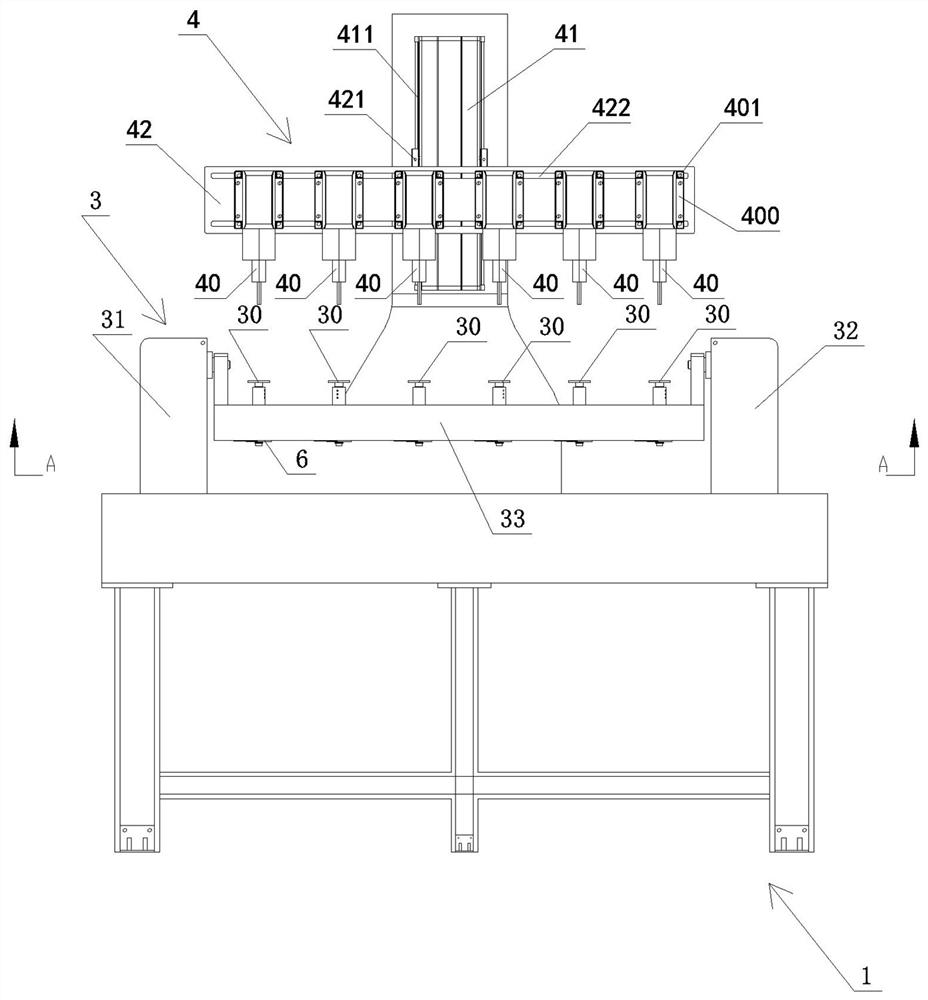

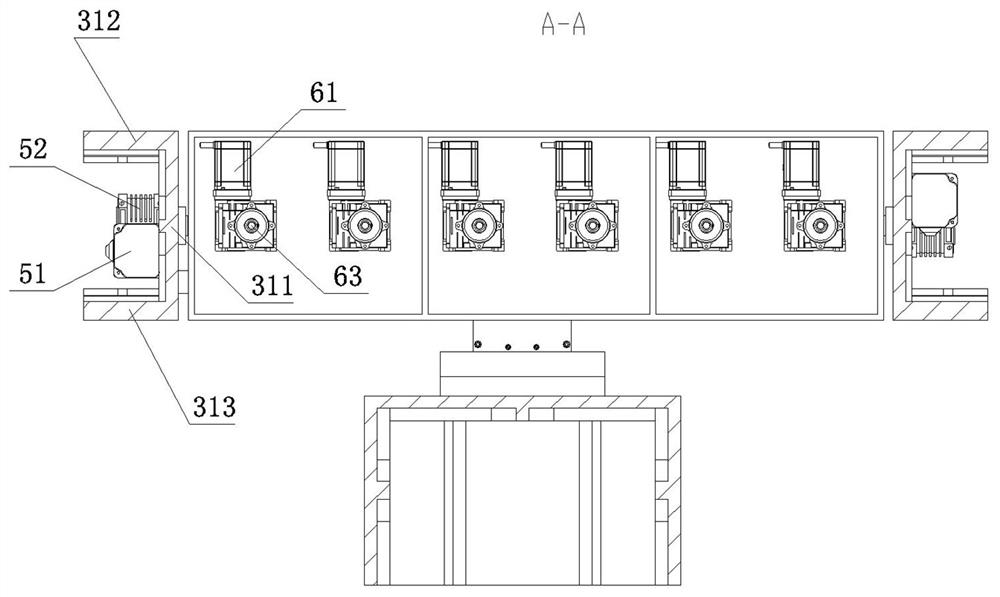

[0033] Reference attached figure 1 , figure 2 , Figure 4 and Figure 7 . A processing device for drilling arc workpieces, comprising a frame 1 and a drilling platform 3 installed on the frame 1 for placing arc workpieces 2, and drilling the arc workpieces 2 on the drilling platform 3 The drilling device 4 of the operation; the drilling platform 3 includes a mold station 30 for placing the arc workpiece 2, a first driving device 5 that drives the mold station 30 to swing, and a second drive that drives the mold station 30 to rotate device6. The design of the drilling platform 3 combined with the first and second driving devices 5 and 6 can realize the automatic drilling operation of arc workpieces with curved surface structures (such as the spout mesh parts of purple sand pots, etc.), which changes the traditional arc workpieces. The unique drilling mode (i.e. using manual or pistol drill to drill holes one by one on the arc workpiece) greatly improves the efficiency of ...

Embodiment 2

[0050] Reference attached Figure 10 . The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that the shape of the mold 7 is different. The matching accommodation cavity 70 , the inner side wall of the accommodation cavity 70 is an inclined side wall with threads, and the arc workpiece 2 (such as a semicircle) to be processed is placed in the accommodation cavity 70 . The accommodating cavity 70 adopts the design of the inclined inner wall with threads, so that the arc-shaped workpiece 2 is placed in the accommodating cavity 70, and its bottom edge is subjected to the friction force of the thread, so it is not easy to loosen or shift. It is also convenient to take out the arc workpiece 2 after the punching operation is completed.

[0051] In addition, the mold 7 can also be a cylindrical mold, and the interior of the cylindrical mold is provided with an accommodation cavity 70' that matches the lower part of another arc workpi...

Embodiment 3

[0053] Reference attached Figure 12 . The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that: a processing equipment for punching circular arc workpieces, which also includes a feeding table 81 for placing the circular arc workpieces 2 to be processed and a processed The discharge table 82 on which the arc workpiece 2 is placed, the feed table 81 and the discharge table 82 are respectively located on the left and right sides of the frame 1 . The frame 1 is provided with a waste collection tray 91 for accepting the waste generated during the drilling operation of the arc workpiece 2 , and the waste collection tray 91 is located directly below the drilling platform 3 . The bottom of the waste collection tray 91 communicates with a waste discharge pipe 92 for discharging the waste therein.

[0054] In addition, the number of the processing equipment can be multiple (such as two, four, or six, etc.) arranged in sequence, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com