Perforating machine capable of improving production efficiency

A production efficiency and punching machine technology, applied in the field of punching machines, can solve the problems of time-consuming and laborious production efficiency, affecting product quality, etc., and achieve the effects of improving production efficiency, ingenious structural design, and ideal structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

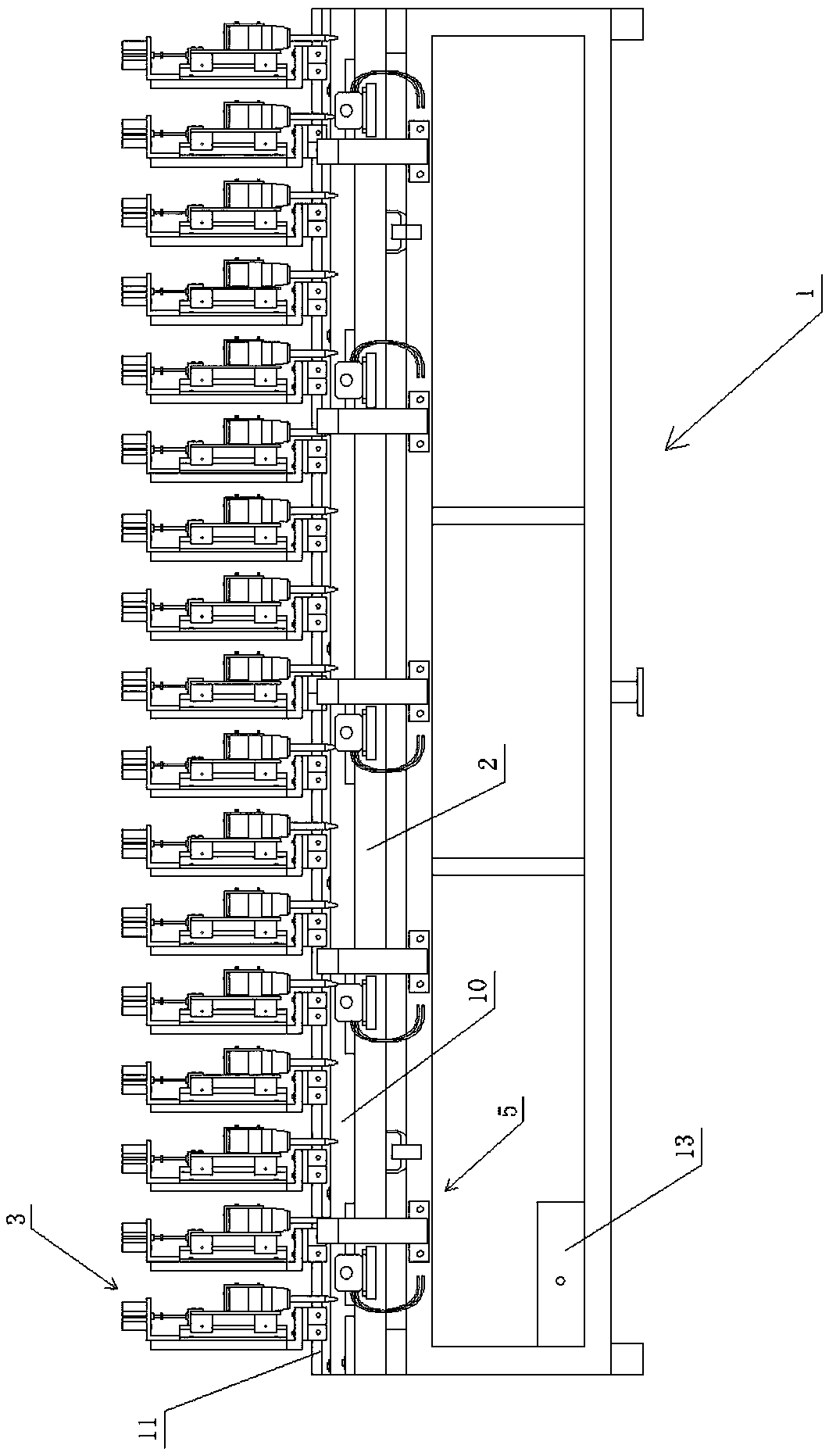

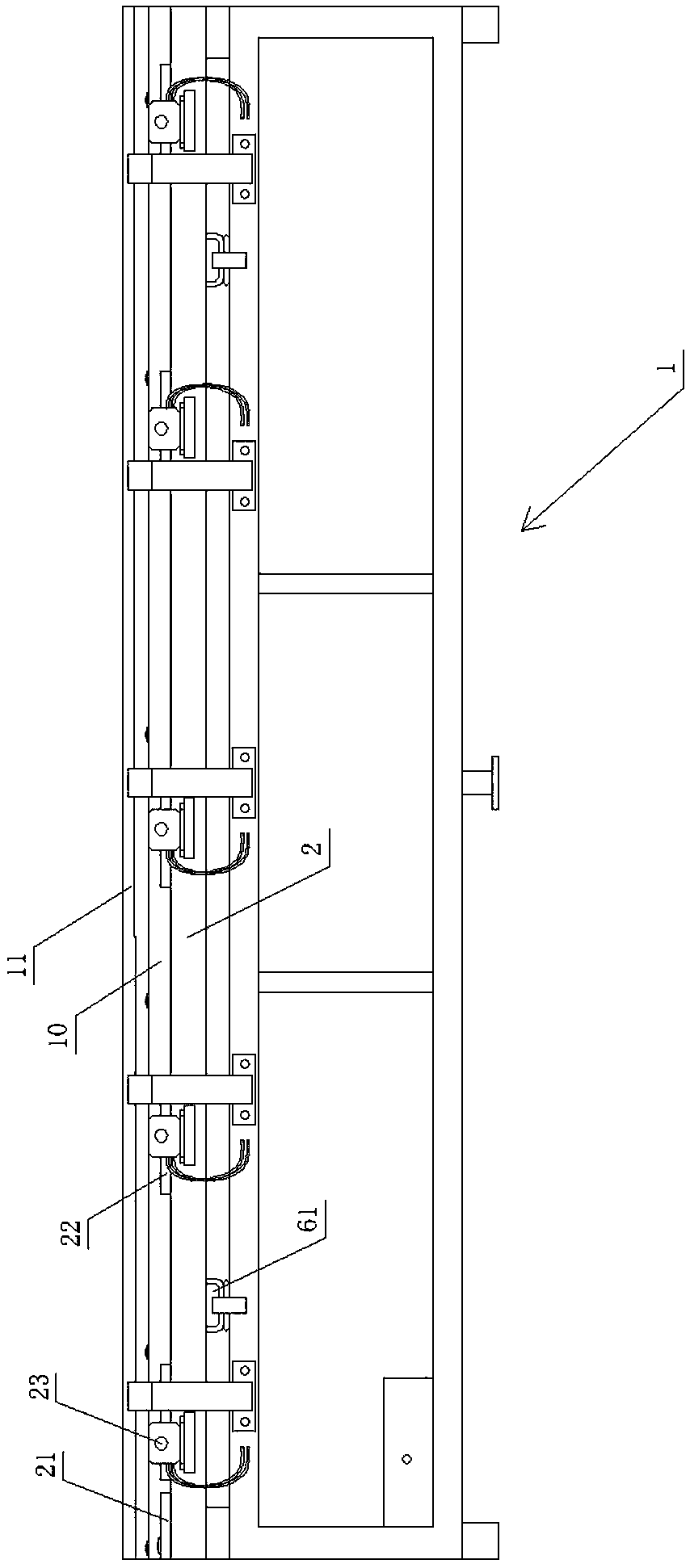

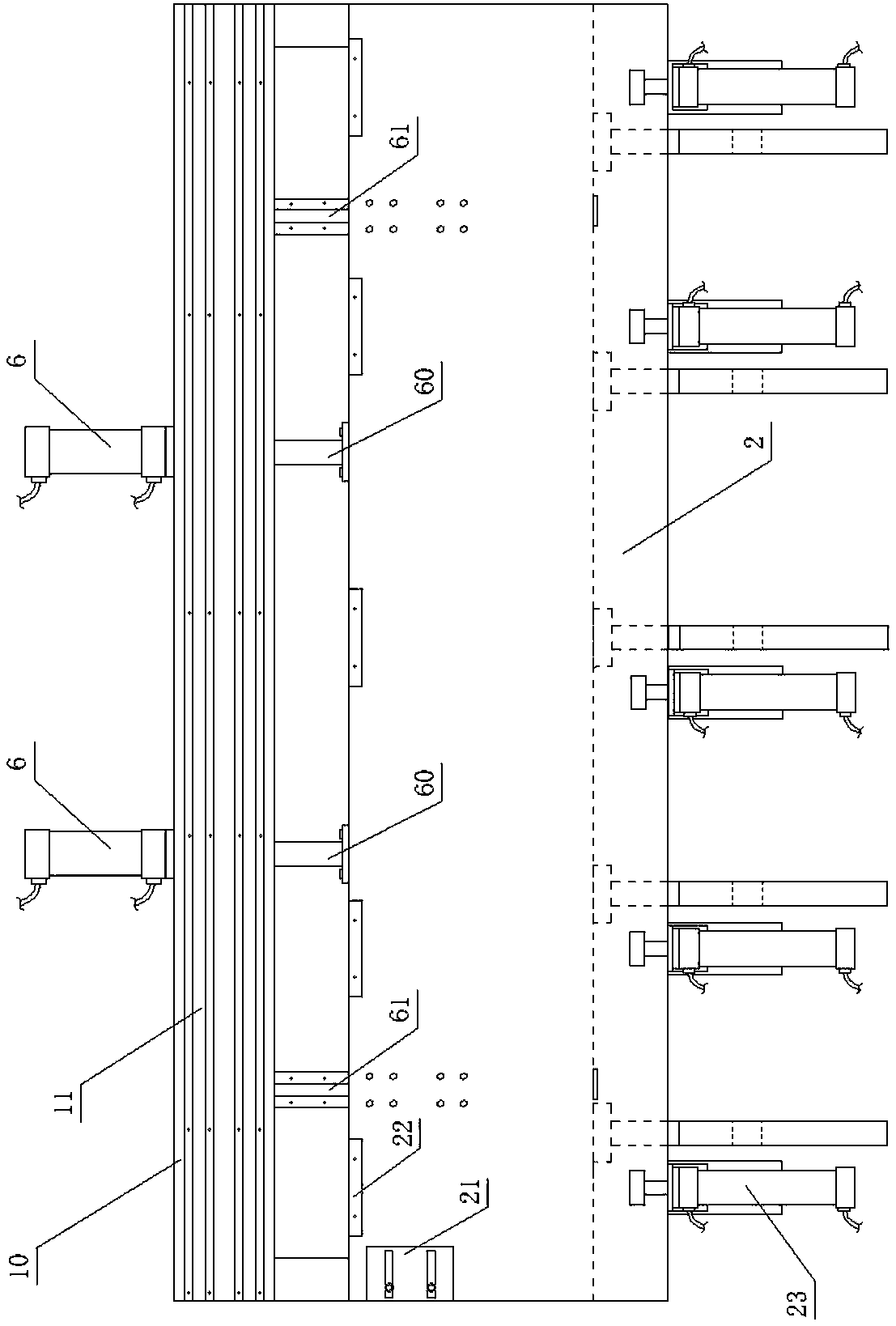

[0028] Refer to attached figure 1 , image 3 and Figure 4 . A punching machine for improving production efficiency, comprising a frame 1, an operation platform 2 for placing wooden slats and horizontally moving back and forth on the frame 1, and for drilling holes on the wooden slats on the operation platform 2 A plurality of punching heads 3 and a limiting component for limiting the slats on the operating platform 2, the plurality of punching heads 3 are arranged at intervals in sequence along the length direction of the frame 1. The front end of the frame 1 is also provided with a plurality of placement brackets 5 for temporarily placing wooden slats, and the plurality of placement brackets 5 are arranged at intervals in sequence along the length direction of the operating platform 2 . Each putting support 5 comprises the first horizontal rod 51 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com