Dipolythiohexafluoroacetone production device and production process

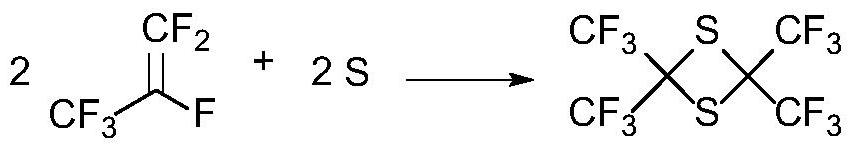

A technology for dimerization of thiohexafluoroacetone and a production device, which is particularly applied in the field of corrosion resistance, can solve the problems of low conversion rate of hexafluoropropylene, difficult waste liquid treatment, low product purity and the like, and achieves durability. and safety guarantee, short reaction time and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

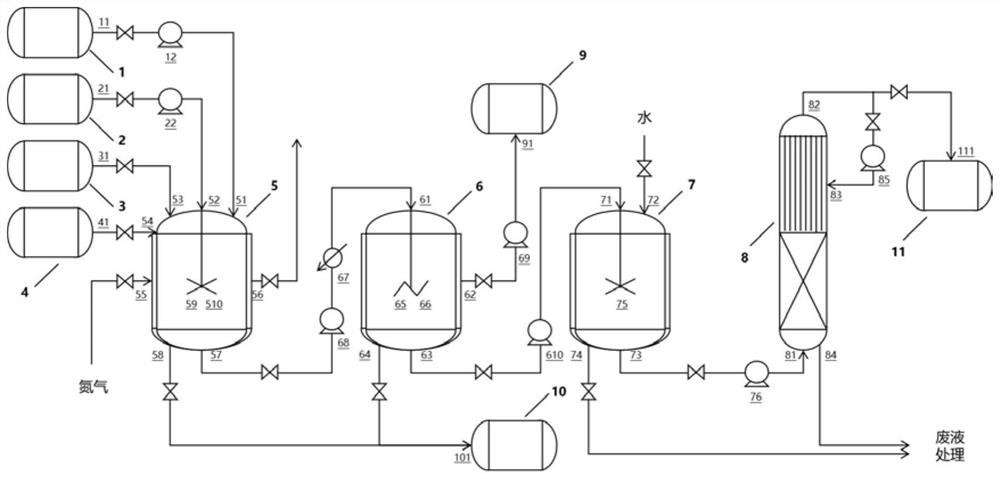

[0034] 1. Dimerized thiohexafluoroacetone production device

[0035] Refer to attached figure 1 , Dimerized thiohexafluoroacetone production device consists of solvent storage tank 1, hexafluoropropylene storage tank 2, catalyst storage tank 3, sulfur raw material storage tank 4, reaction kettle 5, cooling crystallization kettle 6, water washing kettle 7, rectification tower 8. Solvent recovery tank 9, solid recovery tank 10, product storage tank 11;

[0036] The outer wall of the reaction kettle 5 is provided with a heating jacket around the outer wall, a solvent inlet 51, a hexafluoropropylene inlet 52, a catalyst inlet 53, and a sulfur raw material inlet 54 are arranged on the top, an air inlet 55 and an exhaust outlet 56 are arranged on the side, and a A liquid outlet 57 and a solid outlet 58 are provided with a stirring device 59 and a temperature monitoring device 510 inside; the outer wall of the cooling crystallization kettle 6 is provided with a cooling and heating l...

Embodiment 2~5

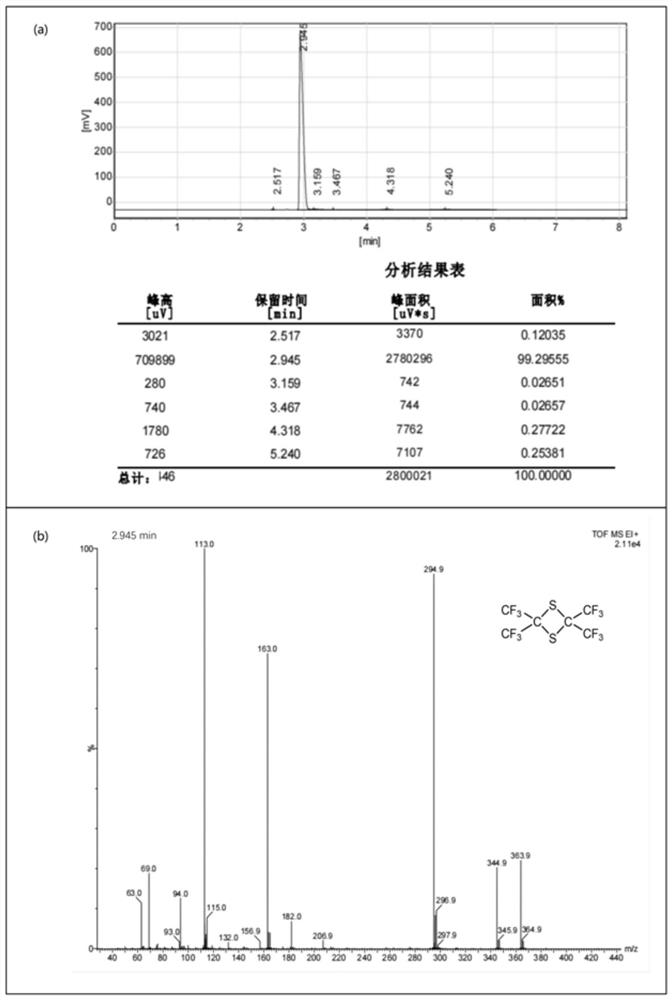

[0051] In Example 1, step 2) material ratio, preheating temperature in the reactor, hexafluoropropylene ventilation rate, reaction temperature, reaction pressure, reaction time; step 3) crystallization temperature, crystallization time, and washing times are respectively changed into As shown in Table 1, other operations are the same as in Example 1, and the purity and yield of the obtained dimeric thiohexafluoroacetone are shown in Table 1.

[0052] Process synthesis under different equipment and reaction conditions in table 1

[0053]

Embodiment 6

[0055]18L of the cooling residual liquid collected in step 3) of the solvent recovery tank 9 of Example 1 is directly used as a solvent, and 2 L of dimethylformamide is added to make up 20 L as a solvent. Meanwhile, the sulfur solid in the solid recovery tank 10 is heated at 80° C. After drying under vacuum for 4 hours, the obtained 2.0 kg of recovered sulfur was used as part of the sulfur raw material, and 13.30 kg of sublimed sulfur was supplemented as the sulfur raw material. Other operations were the same as in Example 1. The purity of dimeric thiohexafluoroacetone was 99.3%, and the yield was 95.5%. Table 2 shows the impact of recycling times on the yield.

[0056] Table 2 Solvent and the impact of the recycling number of sulfur solids on the product yield

[0057]

[0058] As can be drawn from Table 2, the mechanical application times of solvent and sulfur solid have little effect on the reaction yield, and the solvent and raw materials recovered and reused can be rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com