Preparation method of hydrophobic composite nanofiber air filtering membrane

A composite nanofiber and air filtration technology, which is applied in the direction of separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of complex process, high cost, and restrictions on wide application, and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare solution one:

[0042] Add 10g of polyvinylidene fluoride PVDF with a molecular weight of 40W and 0.005g of lithium chloride LiCl to 40g of N,N-dimethylformamide DMF, stir at 70°C for 4h, and the speed is 200r / min, and the concentration is 20%. PVDF solution, the solution is light yellow and defoamed before spinning or standing for 12h.

[0043] Preparation solution two:

[0044]Add 5g of polyvinylidene fluoride PVDF with a molecular weight of 6.2W into 45g of N,N-dimethylformamide DMF, stir at 70°C for 4h at a speed of 200r / min, and prepare a PVDF solution with a concentration of 10%. The solution is Light yellow defoaming or standing for 12 hours before spinning.

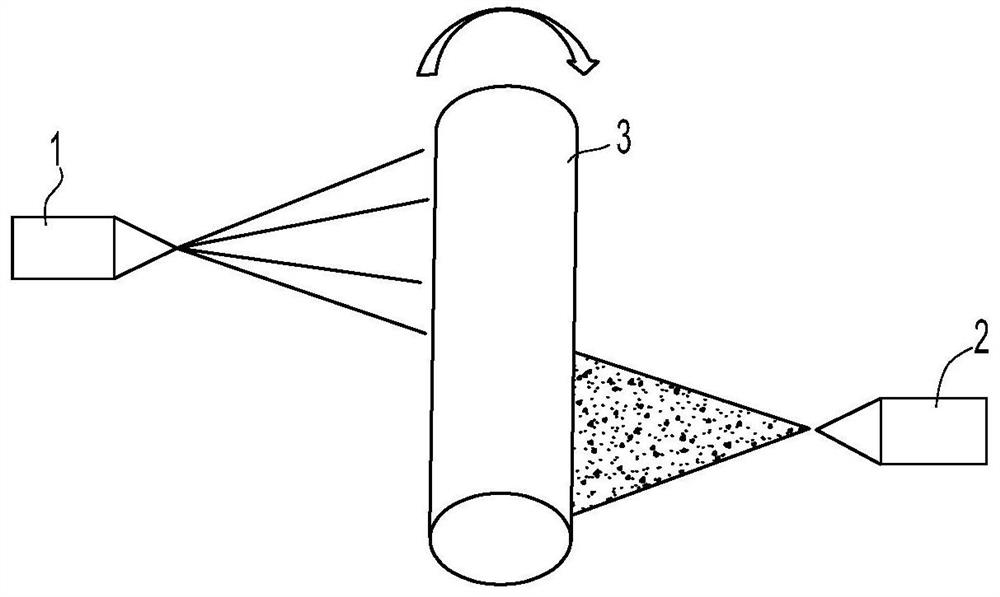

[0045] Fill the solution 1 and the solution 2 into the syringe respectively, adjust the spinning parameters, and simultaneously spray and blend them, and spin them for 1 hour to obtain the blended membrane. Counter-jet blend reference figure 1 As shown, the middle is the collector 3, and the two...

Embodiment 2

[0060] Preparation solution 1: Add 9g of polyvinylidene fluoride PVDF with a molecular weight of 40W and 0.01g of sodium dodecylbenzenesulfonate to 41g of N,N-dimethylformamide DMF, stir at 70°C for 4h, and rotate at 200r / min, to prepare a PVDF solution with a concentration of 18%, and then add 0.9g of SiO2 nanoparticles into the solution, ultrasonically vibrate for 30min, defoam or stand still for 12h before spinning.

[0061] Preparation Solution 2: Add 2.5g of polystyrene PS with a molecular weight of 3W to 47.5g of N,N-dimethylformamide DMF, stir at 60°C for 2 hours, and prepare a solution with a concentration of 5%. PS solution, defoaming or standing for 12 hours before spinning.

[0062] Fill solution 1 and solution 2 into syringes respectively, adjust spinning parameters, and spin for 1 hour to obtain a blended membrane.

[0063] Solution 1: Spinning parameters temperature 25°C, humidity 50%, distance from nozzle tip to receiving end 15cm, receiving end rotating speed...

Embodiment 3

[0067] Preparation solution 1: Add 7g of polyacrylonitrile PAN with a molecular weight of 15W and 0.1g of polyethyleneimine PEI with a molecular weight of 6000 to 43g of N,N-dimethylacetamide DMAC, stir at 60°C for 4h, and rotate at a speed of 200r / min , prepared into a PAN solution with a concentration of 14%, defoaming or standing for 12 hours before spinning.

[0068] Preparation solution 2: Add 3g of polyacrylonitrile PAN with a molecular weight of 9W to 47g of N,N-dimethylacetamide DMAC, stir at 60°C for 2h, and the rotation speed is 200r / min, and prepare a PAN solution with a concentration of 6%. , Defoaming or standing for 12h before spinning.

[0069] Fill solution 1 and solution 2 into syringes respectively, adjust spinning parameters, and spin for 1 hour to obtain PAN blended membrane.

[0070] Solution 1: Spinning parameters temperature 25°C, humidity 50%, distance from nozzle tip to receiving end 15cm, receiving end rotating speed 500rpm, injection speed 30ul / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com