Inclination detection method, device and equipment for C-shaped hook and readable storage medium

A technology of tilt detection and tilt angle, which is applied in image data processing, instruments, calculations, etc., can solve the problems of high installation cost, difficult maintenance, high labor cost, etc., and achieve the effect of preventing tipping accidents and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

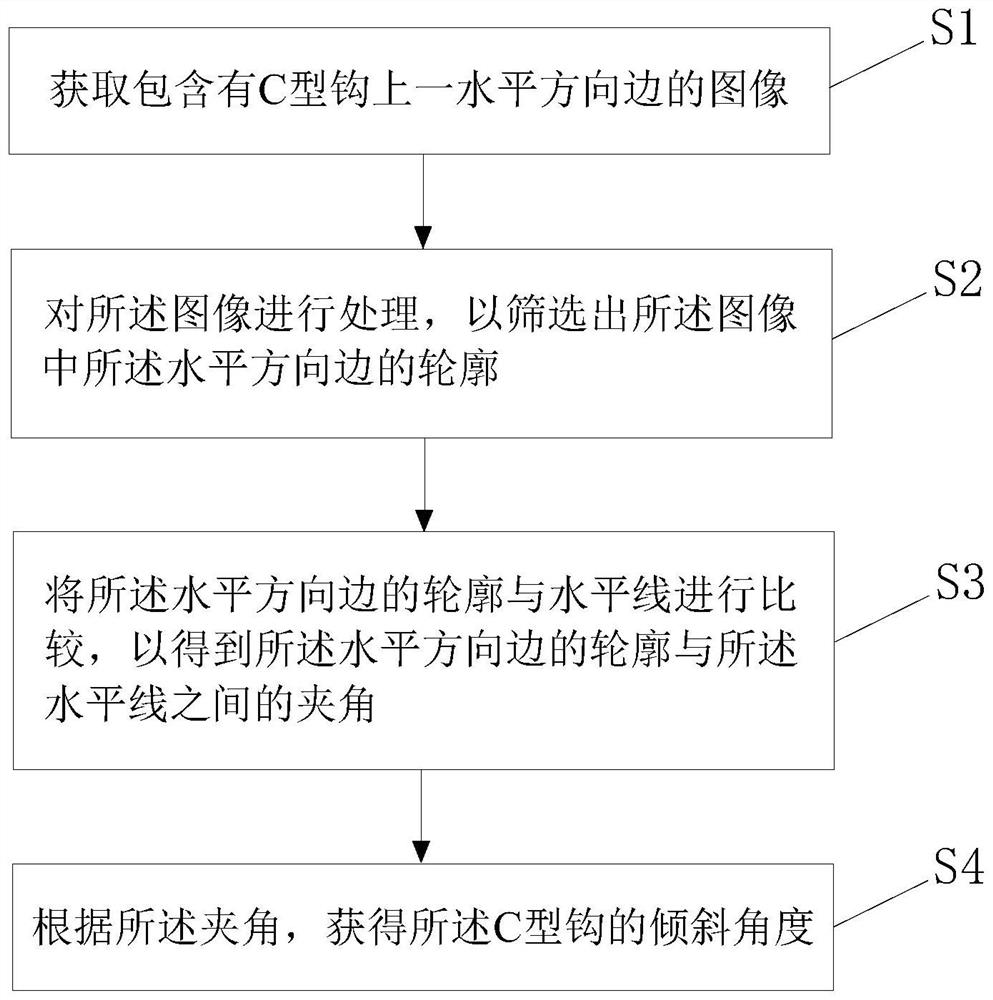

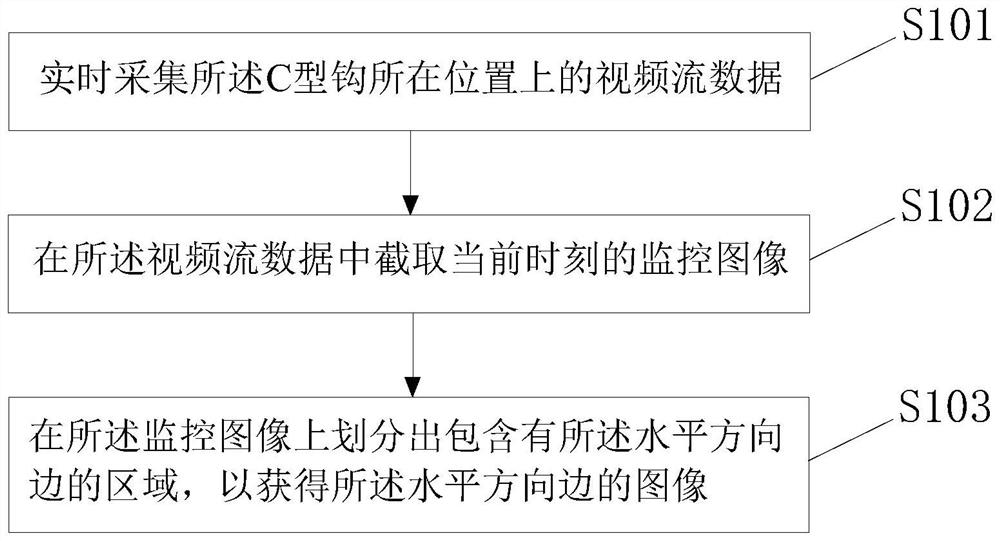

[0100] Such as figure 2 , Figure 6 As shown, the present invention provides a method for detecting the inclination of a C-type hook, which includes the following steps:

[0101] Step S1: Obtain an image containing a horizontal edge on the C-shaped hook;

[0102] Step S2: processing the image to filter out the outline of the horizontal edge on the C-shaped hook in the image;

[0103] Step S3: Comparing the outline of the horizontal edge with the horizontal line to obtain the angle between the outline of the horizontal edge and the horizontal line;

[0104] Step S4: Obtain the inclination angle of the C-shaped hook according to the angle between the contour of the horizontal edge and the horizontal line.

[0105] Step S5: preset the threshold value of the inclination angle of the C-shaped hook;

[0106] Step S6: If it is detected that the inclination angle of the C-hook is greater than the threshold, an external warning is issued.

[0107] In an alternative embodiment of ...

Embodiment approach 2

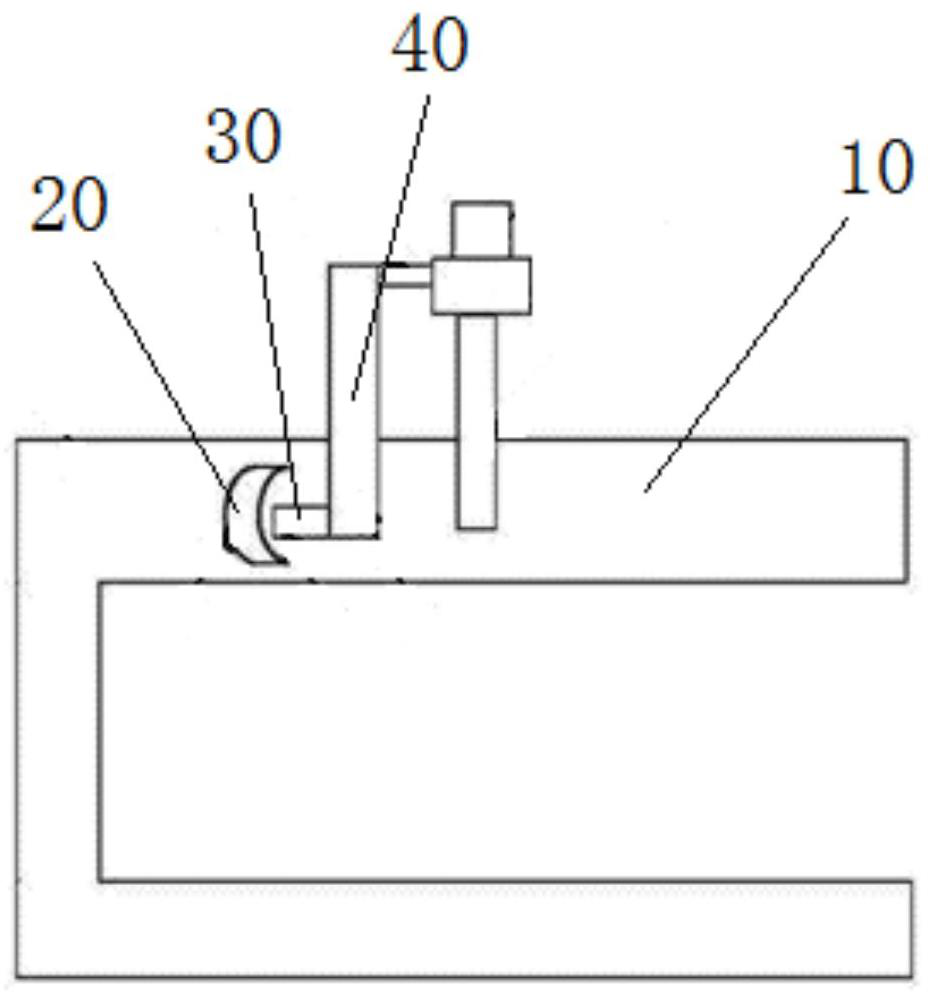

[0143] Such as Figure 7 As shown, the present invention provides a C-type hook inclination detection device, which includes an image acquisition unit 10, a contour screening unit 20, a comparison unit 30 and an inclination angle acquisition unit 40, and the image acquisition unit 10 is used to acquire Contain the image of a horizontal edge on the C-shaped hook; the outline screening unit 20 is used to process the image to filter out the outline of the horizontal edge in the image; the comparison unit 30 is used to compare the outline of the horizontal edge with the horizontal line , to obtain the included angle between the outline of the horizontal edge and the horizontal line; the inclination angle acquisition unit 40 is used to obtain the inclination angle of the C-shaped hook according to the included angle.

[0144] In an alternative embodiment of the present invention, as Figure 8 As shown, the contour screening unit 20 includes an image enhancement module 2001 , an av...

Embodiment approach 3

[0156] The present invention provides a computer device, which includes a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the computer program, the above-mentioned C-hook tilt detection method is realized.

[0157] Specifically, the computer device may be a computer terminal, a server or a similar computing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com