Semiautomatic propelling construction mechanism for bridge parapet

A construction device and semi-automatic technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficulty in finding, breaking the ring, and taking too much time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

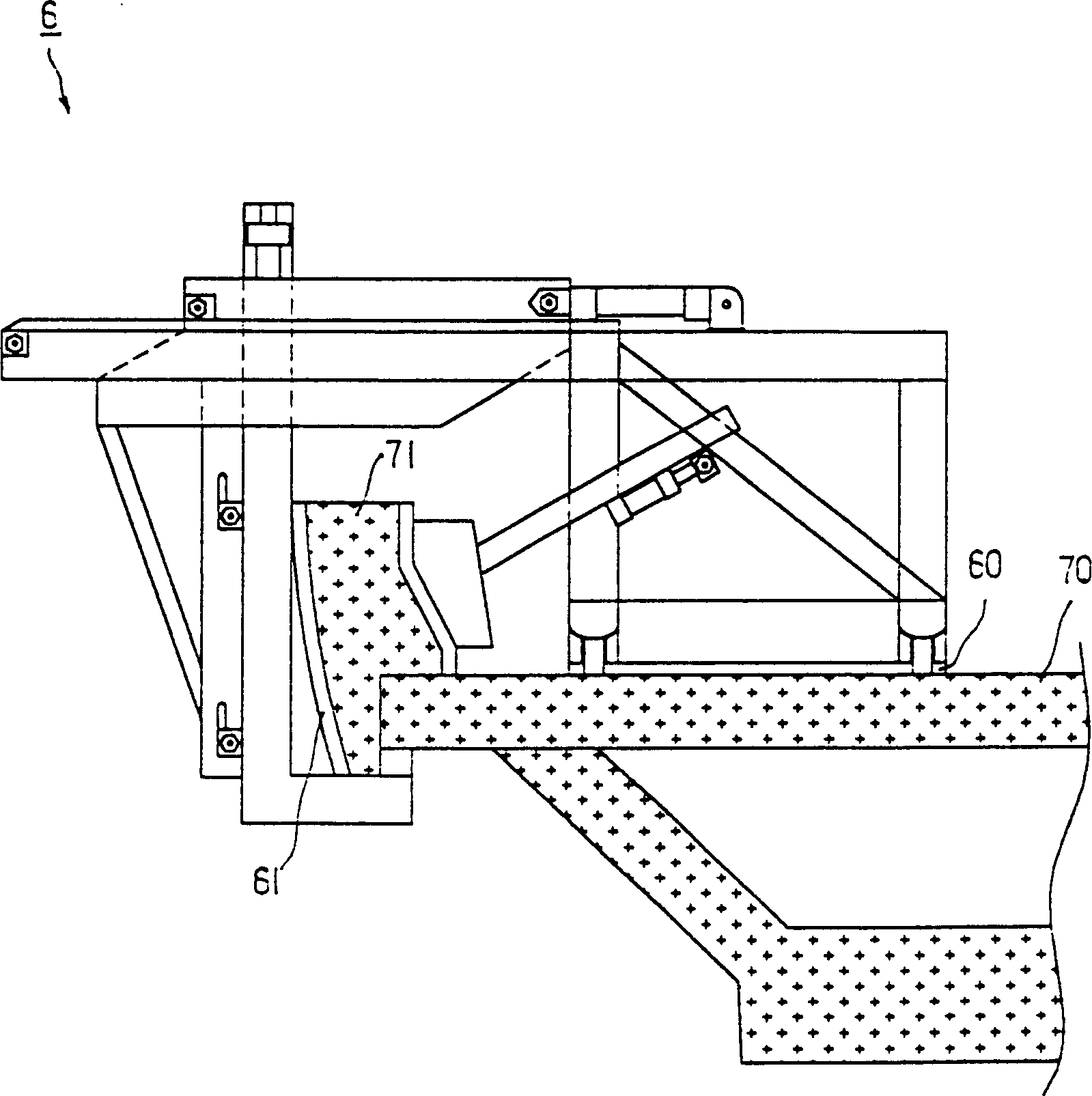

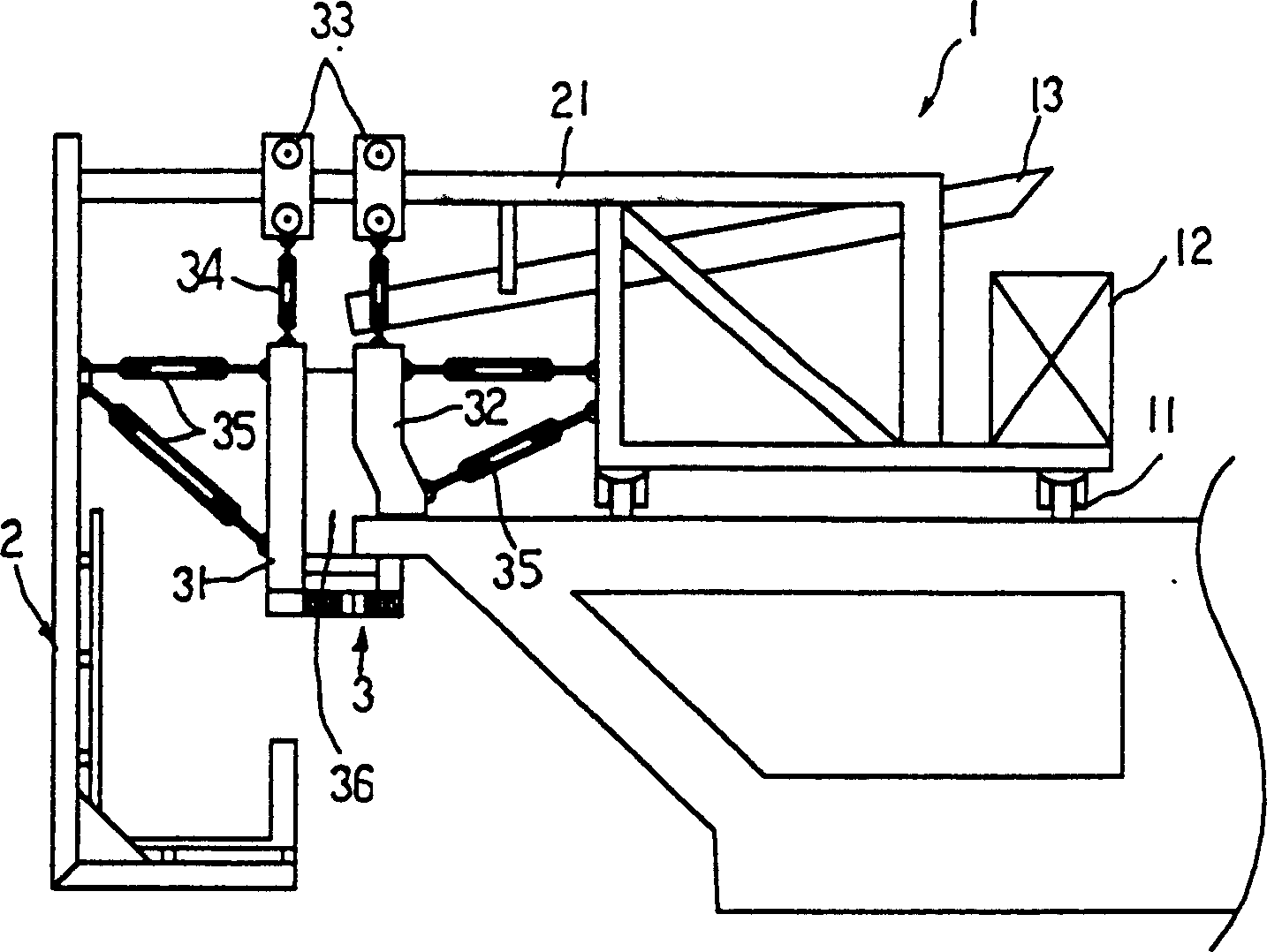

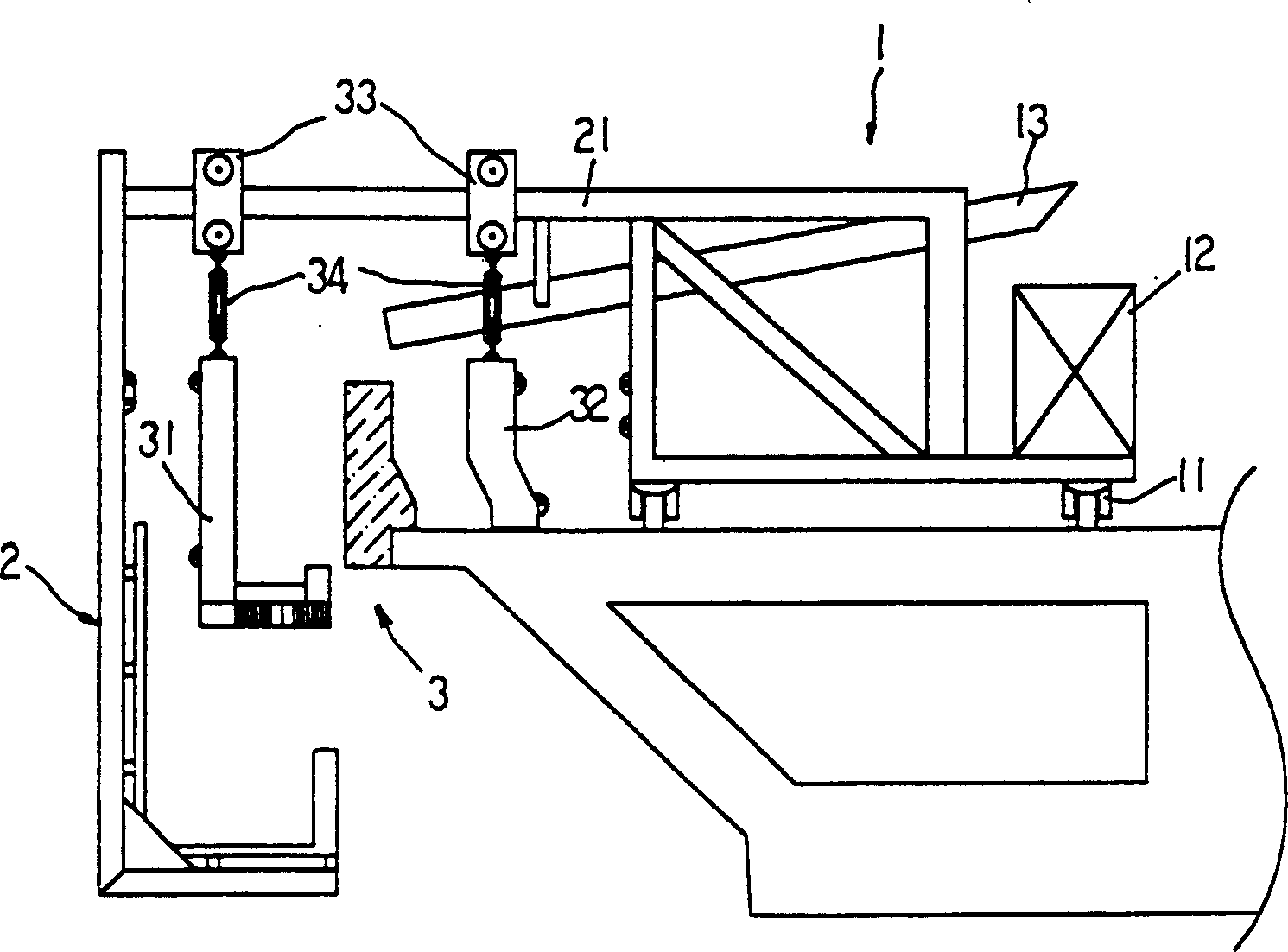

[0014] refer to figure 1 , 2 , bridge parapet semi-automatic propulsion construction device, mainly includes:

[0015] The workbench 1 is a work platform, and a wheel body 11 is arranged at the bottom of the workbench 1, and the wheel body 11 can drive the workbench 1 to move; a counterweight device 12 can be arranged on one side of the workbench 1, thereby avoiding work The platform 1 is overturned during the construction of the parapet of the bridge, which increases the safety of the construction; a beam 21 is extended on the other side of the working platform 1 .

[0016] The construction frame 2 is set on the beam 21 extending from the workbench 1, and can be attached to other components. Its main function is to allow the construction personnel to further inspect the construction situation on the outside or bottom of the bridge parapet, and to grasp the other side of the bridge parapet at any time. The construction situation and quality of the workbench 1 are combined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com