Distributed biomass and waste incineration treatment system

A technology of waste incineration and treatment system, which is applied in the field of distributed biomass and waste incineration treatment system, can solve the problem that distributed biomass and domestic waste are not easy to be incinerated and dealt with together, and saves fans, saves energy, and has high resource utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

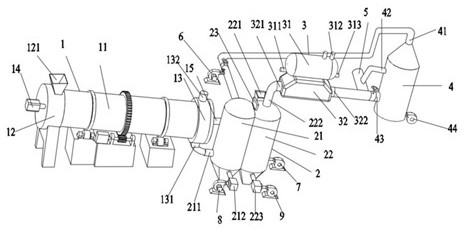

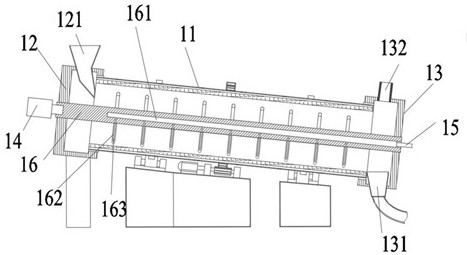

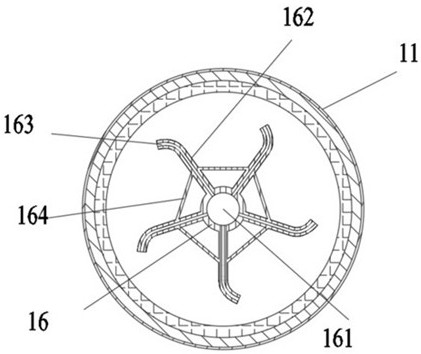

[0039] Embodiment one, a distributed biomass and waste incineration treatment system, such as figure 1 As shown, it includes a biomass drying cylinder 1, an incinerator 2, a waste heat boiler 3, and a heat exchanger 4 connected in sequence. The biomass drying cylinder 1 includes a cylinder body 11, which is inclined to make the biomass material flow toward the The outlet moves, the cylinder body 11 is provided with the first head 12 at one end, and the second head 13 at the other end. The feed port 121 is provided, and the feed port 121 extends into the cylinder 11 for inputting crushed biomass. The upper part of the second head 13 is provided with a waste gas port 132 for discharging the waste gas produced by drying, and the lower part is provided with a discharge port. The port 131 is used to discharge the dried biomass. The waste gas port 132 and the discharge port 131 are connected to the inside of the cylinder 11. The cylinder 11 is driven by the drive motor to rotate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com