Rock-entering grooving construction method by matching small-diameter down-the-hole hammer with slot milling machine

A technology of trough construction and down-the-hole hammer is applied in excavation, infrastructure engineering, earth mover/shovel and other directions, which can solve the problems of long maintenance time, high construction cost, and large loss of rotary drilling bits. The equipment occupies a small area, the equipment usage fee is low, and the effect of reducing construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

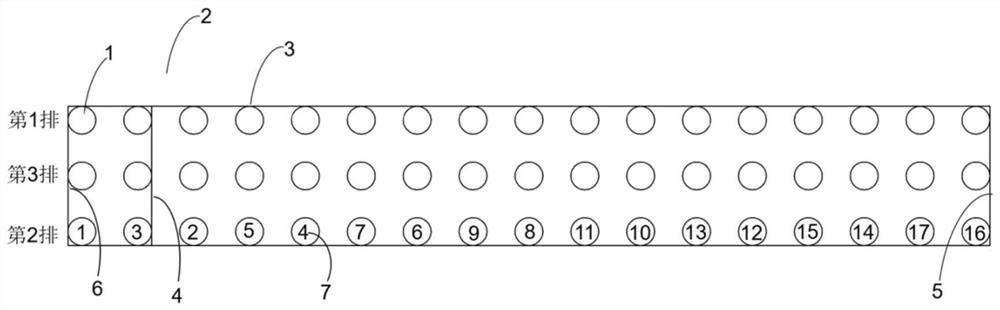

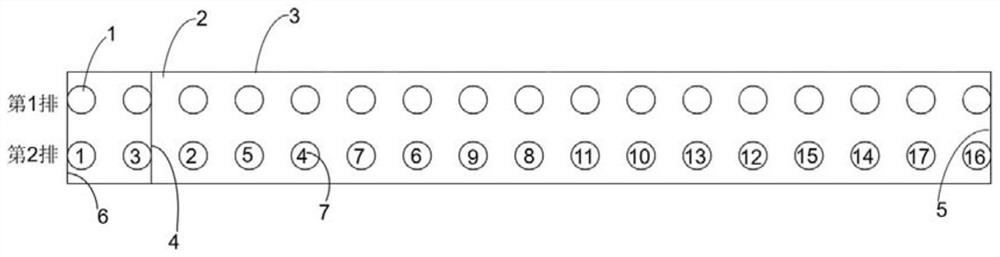

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

[0032] The small-diameter down-the-hole hammer cooperates with the milling machine to enter the rock to form the groove. The small-diameter down-the-hole hammer is used to guide the hole first. The small-diameter down-the-hole hammer uses a small-diameter hammer with a diameter of 200mm. Pneumatic impact tool, the part of the small-diameter down-the-hole hammer that enters the formation includes a drill pipe, casing, hammer body and hammer head. The air with a certain pressure provided by the air compressor drives the piston in the cylinder of the small-diameter down-the-hole hammer to move repeatedly in the axial direction, so that the hammer head at the end of the down-the-hole hammer rotates while producing impact performance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com