A construction method of a large-diameter rock-socketed anti-floating bolt and a drilling tool used in the method

A technology of anti-floating anchor rods and construction methods, which is applied in the direction of earthwork drilling, drilling equipment and methods, and drill pipes, can solve problems such as high cost, high difficulty, and unstable hole walls, and achieve high construction efficiency and high construction efficiency. Simple, Managerial Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

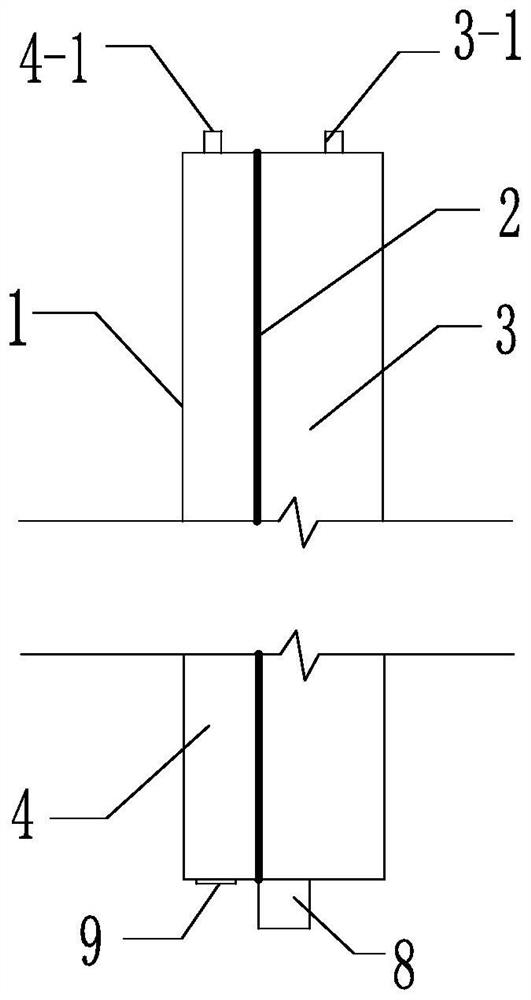

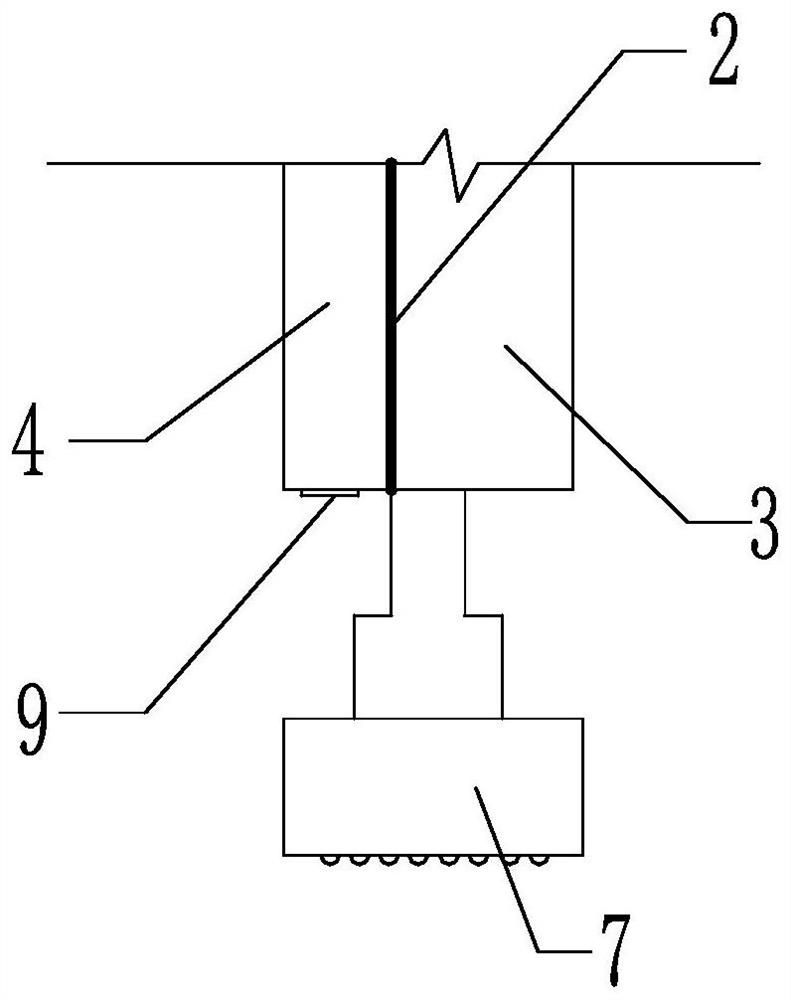

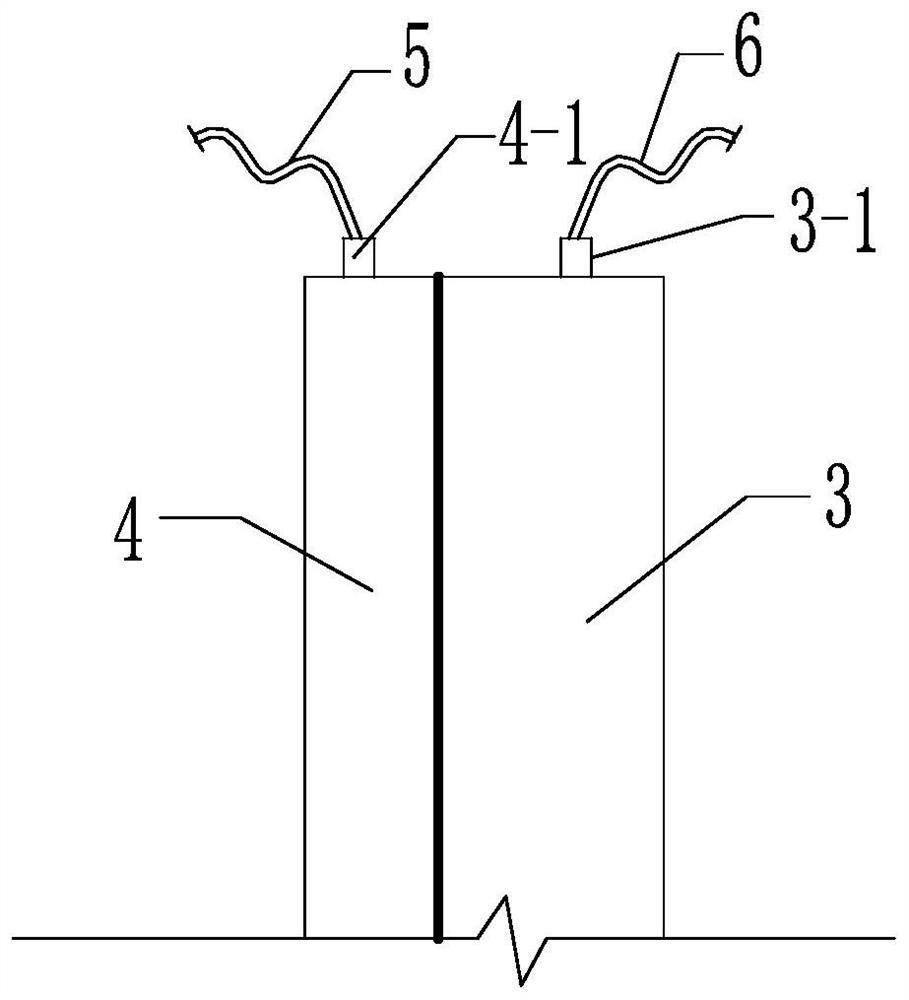

[0028] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1 to Figure 3 As shown, the drilling tool used in the construction method of large-diameter rock-socketed anti-floating bolts in the present invention specifically includes a drill rod 1 and an air down-the-hole hammer 7, and the drill rod 1 is a square drill rod, and the square drill rod The side length of the square is 145-155mm, and the length of the diagonal side is 210-215mm; the bottom of the drill pipe 1 is provided with an air down-the-hole hammer connection port 8, and the air down-the-hole hammer 7 is connected to the drill pipe through the air down-the-hole hammer connection port 8. 1 connection; the inner cavity of the drill pipe 1 is separated along the axial direction of the drill pipe by a steel plate 2 to form an air delivery channel 3 and a grouting channel 4, and the air down-the-hole hammer connection port 8 is placed below the air delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com