A kind of drill device with arc joint

A drill bit and arc-shaped technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of difficulty, deflection of joint pipes, casting in concrete joint holes, etc., to achieve quick installation and use, reduce friction, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

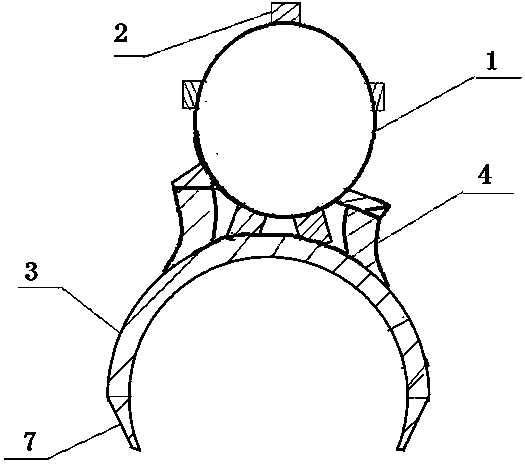

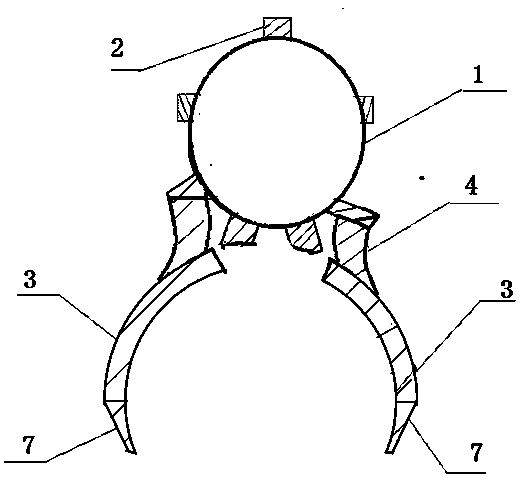

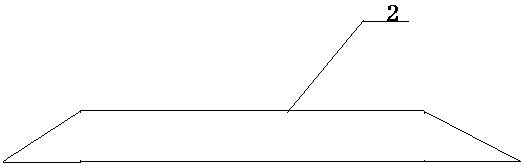

[0020] Such as figure 1 Among them, a drill bit device with an arc-shaped joint includes a plurality of steel bars 2 arranged on the surface of the drill bit 1 (preferably, the distance between adjacent steel bars 2 is 50mm, and the adjacent steel bars 2 are staggered from each other), preferably ,Such as Figure 5 Among them, both ends of the steel bar 2 are slope-shaped, and the arc-shaped plate 3 (for a semi-circular arc steel pipe, its arc is 180 degrees, and the arc-shaped plate can also be any arc that the arc is less than 360 degrees, and the arc can be 15 degrees, 60 degrees degrees, 70 degrees, etc.) the head is connected to the steel bar 2 through the connecting steel plate 4, and connected to the drill bit 1 through the steel bar 2, such as figure 2 Among them, the semicircular arc steel pipe 3 side is provided with side knife edge 7.

[0021] preferred, such as Figure 6 Among them, the bottom of the arc-shaped plate 3 is provided with a connecting part (the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com