Anti-collision roller way of industrial heating furnace

A heating furnace and anti-collision technology, applied in the field of heating furnace roller table, can solve problems such as rebound, and achieve the effect of ensuring effective operation, large cross-sectional area of oil circuit, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

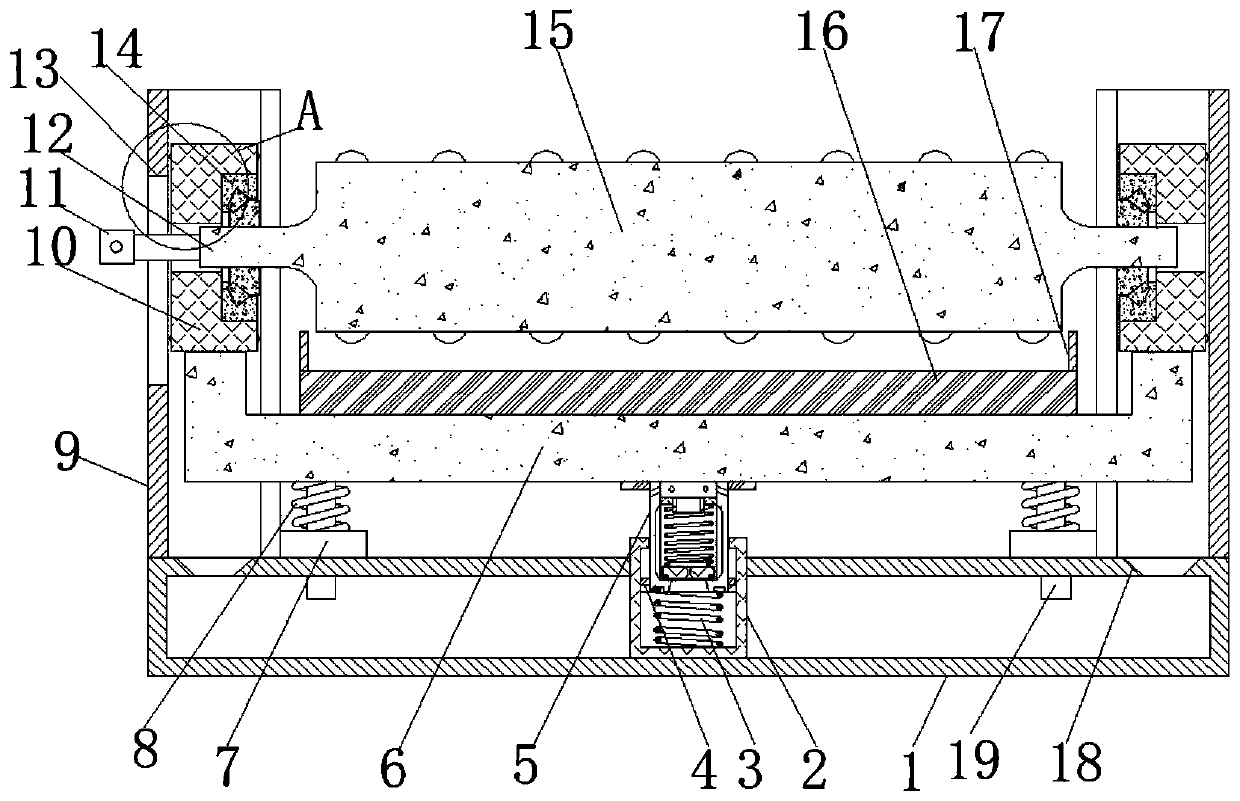

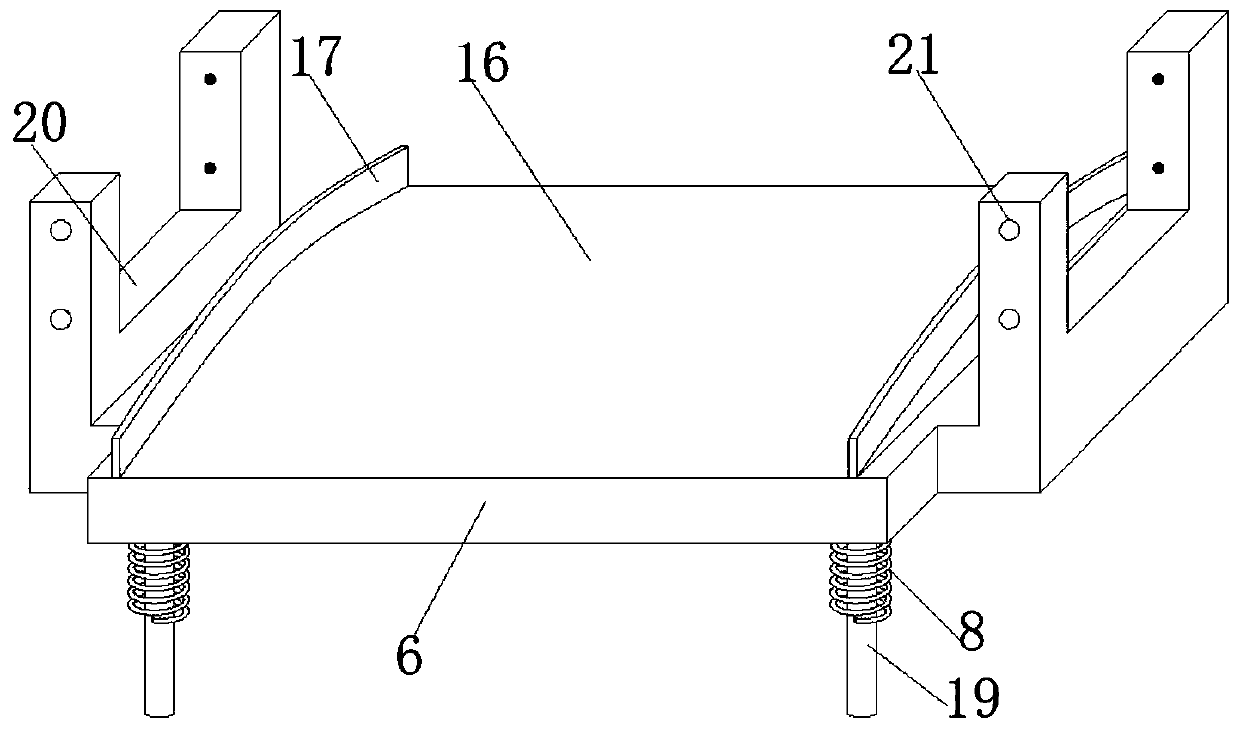

[0029] refer to Figure 1-5 , an anti-collision roller table for an industrial heating furnace, including a support seat 1 with a cavity inside and a cuboid structure, the upper surface of the support seat 1 is respectively fixed with C-shaped steel columns 9 with openings opposite to each other, and two C-shaped steel columns The chute of 9 is slidably connected with a bearing seat 10, and the same transport roller 15 is rotatably connected between the two bearing seats 10, and the same U-shaped bracket with an upward opening is fixed between the lower surfaces of the two bearing seats 10. Plate 6, the lower surface of U-shaped supporting plate 6 is all fixed with guide rod 19 near the four corners, and the side of C-shaped steel column 9 is welded with guide ring 7 matching with guide rod 19 near the bottom end, and guide The upper surface of the ring 7 is fixed with a buffer spring 8, the density of the buffer spring 8 near the bottom is greater than the density at the top,...

Embodiment 2

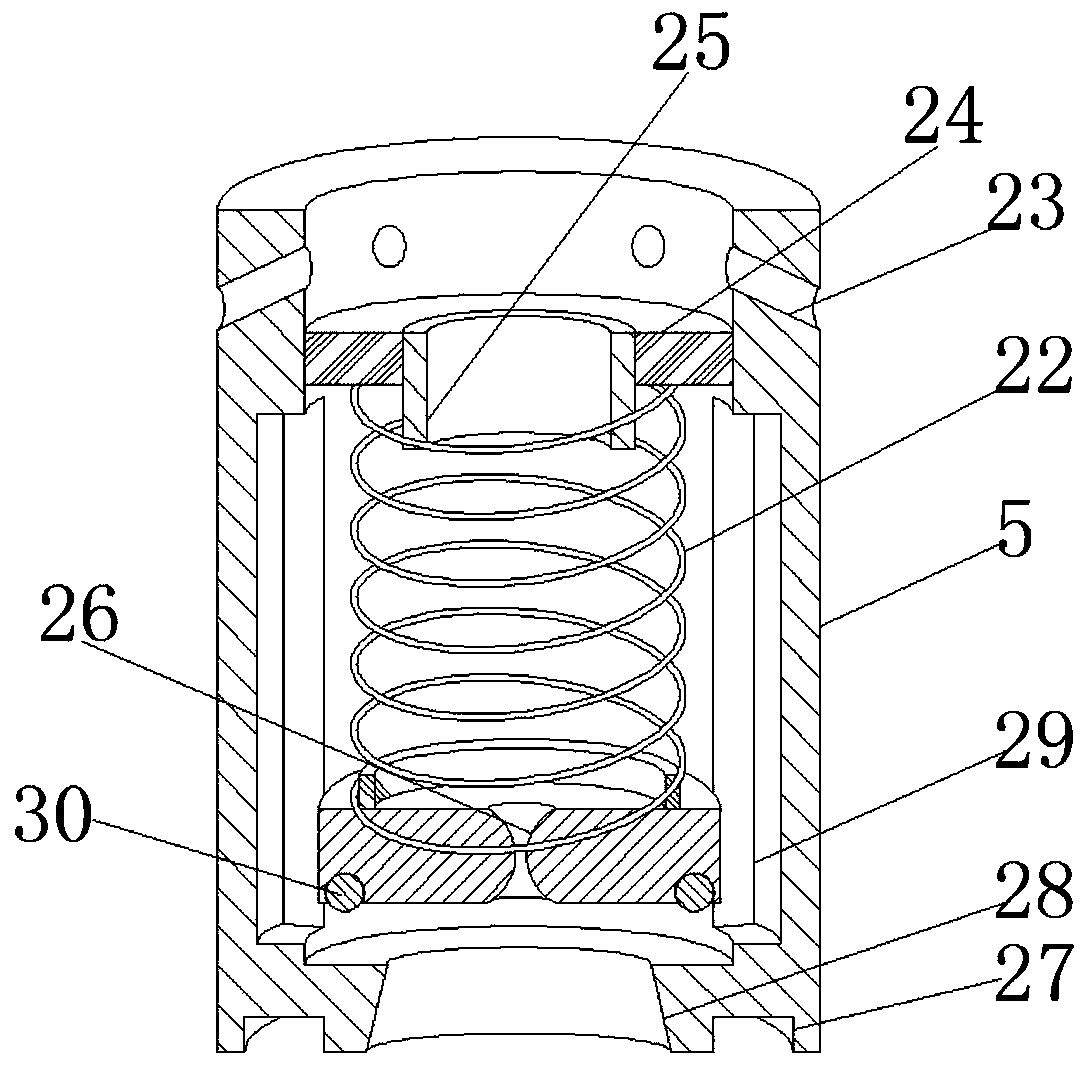

[0039] refer to figure 1 with image 3 , an anti-collision roller table for an industrial heating furnace. Compared with Embodiment 1, this embodiment also includes two mutually symmetrical rectangular grooves 29 on the inner wall of the inner barrel 5 .

[0040] Working principle: The transmission effect of the hydraulic oil is improved, the cross-sectional area of the oil circuit becomes larger, the up and down operation of the hydraulic oil is smoother, and the high-quality operation of the device is ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com