Modification formula for enhancing toughness and prolonging service lifetime of polytetrafluoroethylene

A technology of polytetrafluoroethylene toughness and polytetrafluoroethylene, which is applied in the field of enhanced polytetrafluoroethylene toughness and service life modification formula, can solve the problem of poor sealing performance and service life of single lip structure, and it is difficult to pass a million times Life testing, not being able to fit the sealing surface well, etc., to achieve the effect of reducing the burden on the environment, low production costs, and low machine requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

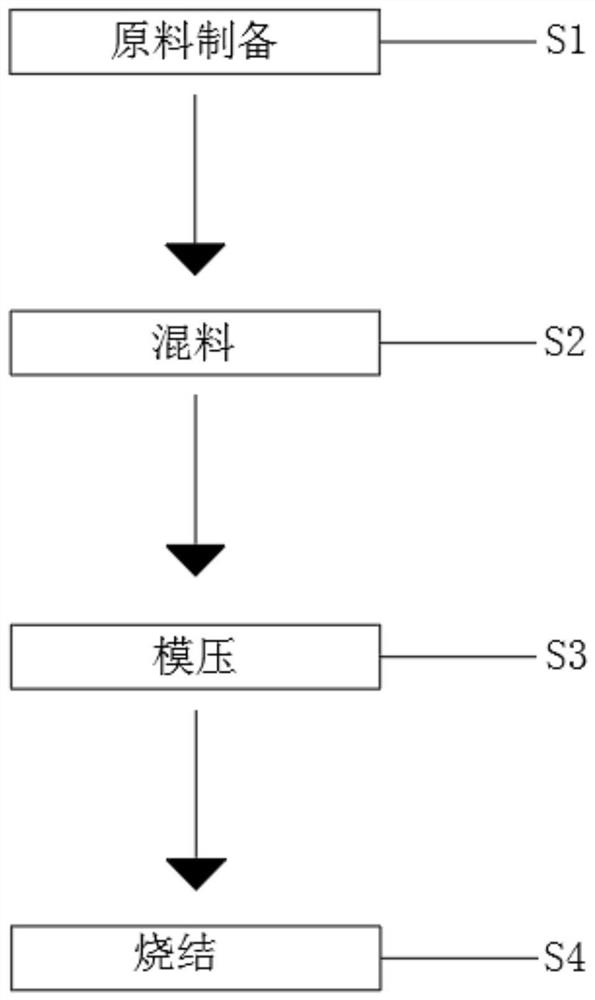

[0027] see figure 1 , a modified formula for enhancing the toughness and service life of polytetrafluoroethylene, comprising the following steps:

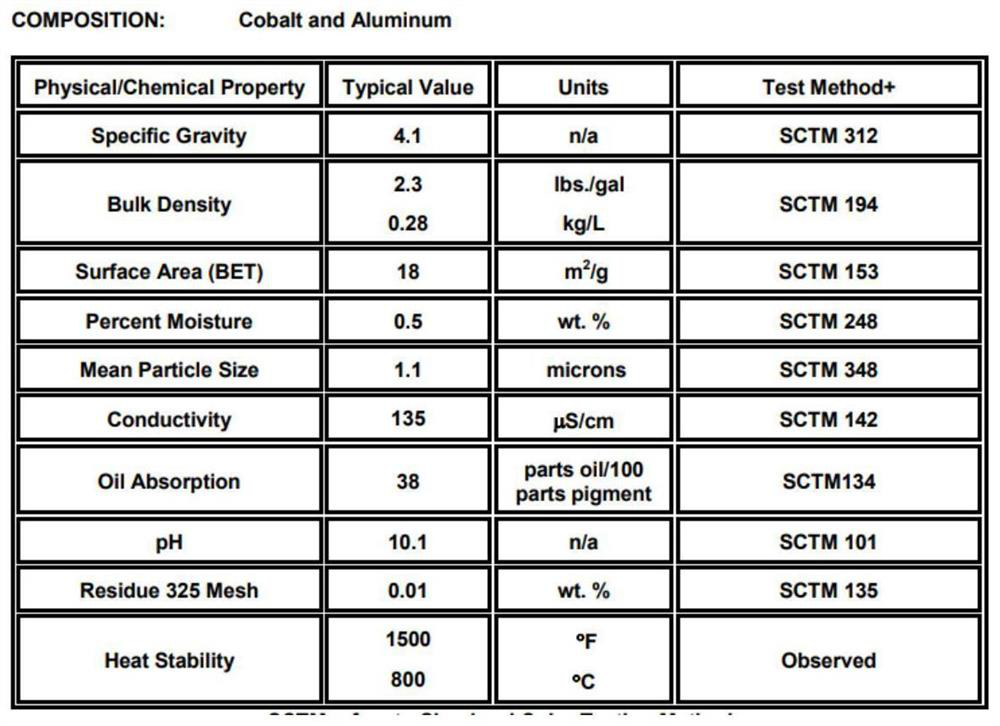

[0028] S1: Raw material preparation, selecting raw materials with a weight ratio of 91% of pure polytetrafluoroethylene powder and 9% of machine masterbatch powder for preparation;

[0029] S2: Mixing materials, placing the tetrafluoroethylene powder obtained in S1 and the machine masterbatch powder in the mixing impurities for mixing to obtain mixed raw materials;

[0030] S3: Molding, placing the mixed raw material obtained in S2 in a molding device, and forming it into a raw material embryo through an isostatic pressing process;

[0031] S4: sintering, the raw material embryo obtained in S3 is heated and shaped by a heating device.

[0032] The pure polytetrafluoroethylene powder in S1 is 100% suspension method polytetrafluoroethylene resin, the appearance is white powder, the technical index of tensile strength is greater tha...

Embodiment 2

[0038] see figure 1 , a modified formula for enhancing the toughness and service life of polytetrafluoroethylene, comprising the following steps:

[0039] S1: Preparation of raw materials, select raw materials with a weight ratio of 95% of pure polytetrafluoroethylene powder and 5% of machine masterbatch powder for preparation;

[0040] S2: Mixing materials, placing the tetrafluoroethylene powder obtained in S1 and the machine masterbatch powder in the mixing impurities for mixing to obtain mixed raw materials;

[0041] S3: Molding, placing the mixed raw material obtained in S2 in a molding device, and forming it into a raw material embryo through an isostatic pressing process;

[0042] S4: sintering, the raw material embryo obtained in S3 is heated and shaped by a heating device.

[0043] The pure polytetrafluoroethylene powder in S1 is 100% suspension method polytetrafluoroethylene resin, the appearance is white powder, the technical index of tensile strength is greater th...

Embodiment 3

[0049] see figure 1 , a modified formula for enhancing the toughness and service life of polytetrafluoroethylene, comprising the following steps:

[0050] S1: Raw material preparation, select raw materials with a weight ratio of 93% of pure polytetrafluoroethylene powder and 7% of machine masterbatch powder for preparation;

[0051] S2: Mixing materials, placing the tetrafluoroethylene powder obtained in S1 and the machine masterbatch powder in the mixing impurities for mixing to obtain mixed raw materials;

[0052] S3: Molding, placing the mixed raw material obtained in S2 in a molding device, and forming it into a raw material embryo through an isostatic pressing process;

[0053] S4: sintering, the raw material embryo obtained in S3 is heated and shaped by a heating device.

[0054] The pure polytetrafluoroethylene powder in S1 is 100% suspension method polytetrafluoroethylene resin, the appearance is white powder, the technical index of tensile strength is greater than o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com