Aluminum template numerical control slot milling machine

A CNC milling machine and aluminum formwork technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of insufficient feeding, setbacks, and steps in aluminum formwork milling grooves, etc., so as to facilitate long-term use , save energy and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following is attached Figure 1-25 The present invention is described in further detail.

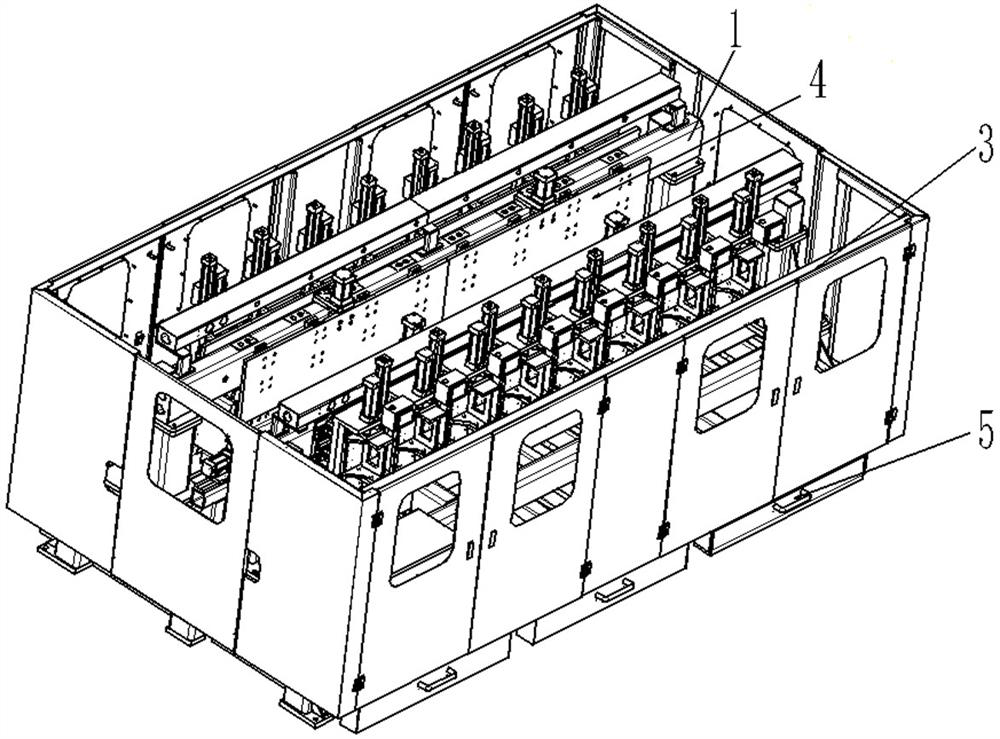

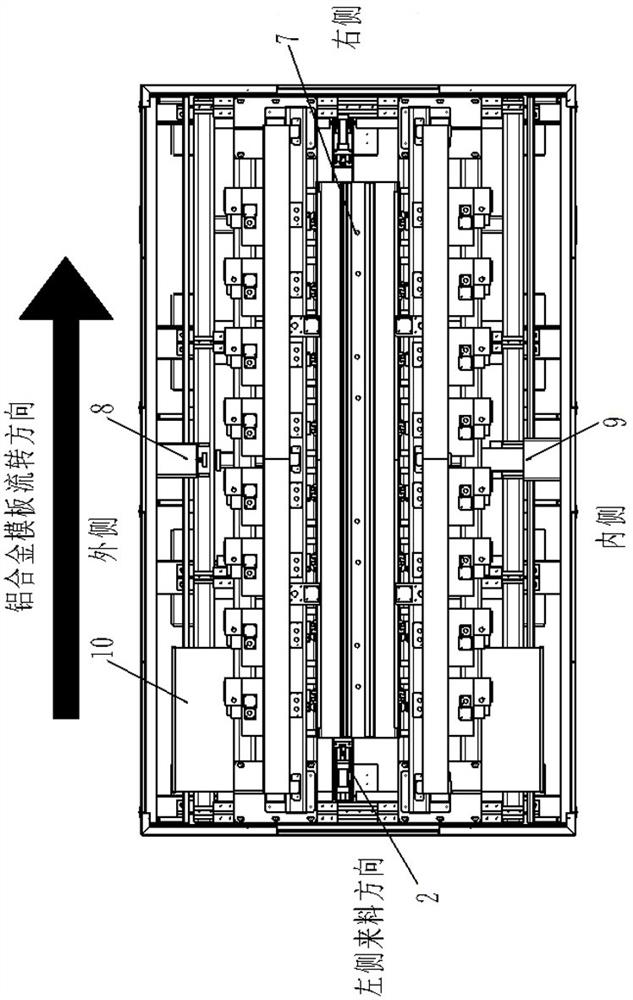

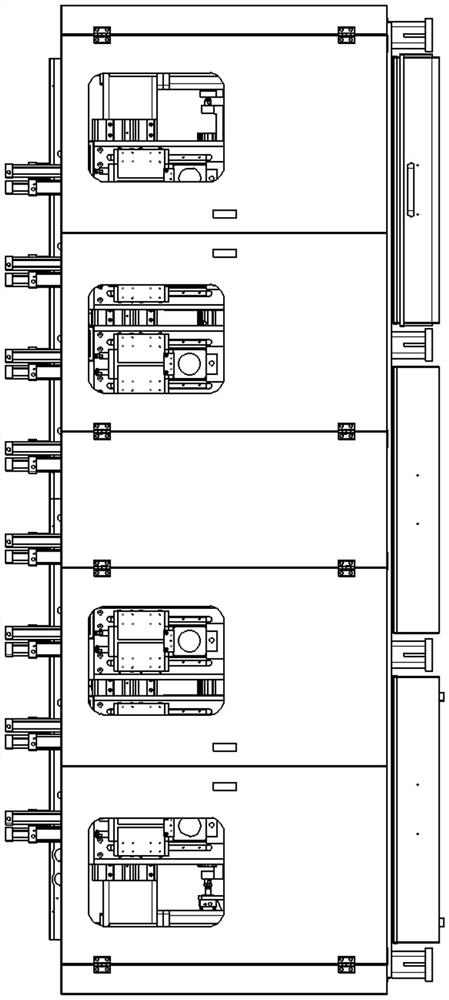

[0060] An embodiment provided by the present invention: as figure 1 with figure 2 As shown, the aluminum template CNC slotting machine has a PLC control system of the prior art, including a protective cover frame 3, and the inner cavity of the protective cover frame 3 is symmetrically provided with feed mechanisms 1 on both sides, and one group is the outer side Traversing feeding mechanism 8, the other group is inner traversing feeding mechanism 9, and the left end of the side where the outer traversing feeding mechanism 8 and the inner traversing feeding mechanism 9 are far away from each other is provided with a power distribution cabinet 10. The electric cabinet 10 is installed in the protective cover frame 3, and the upper end of the side where the two groups of feeding mechanisms 1 are close to each other is provided with a pressing mechanism 4, such as figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com