Henhouse dust removal device

A technology of dust removal device and chicken house, which is applied in poultry cages or houses, cleaning hollow objects, poultry industry, etc., can solve the problems of inability to clean and collect feces, and achieve the effect of reducing the difficulty of cleaning and increasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

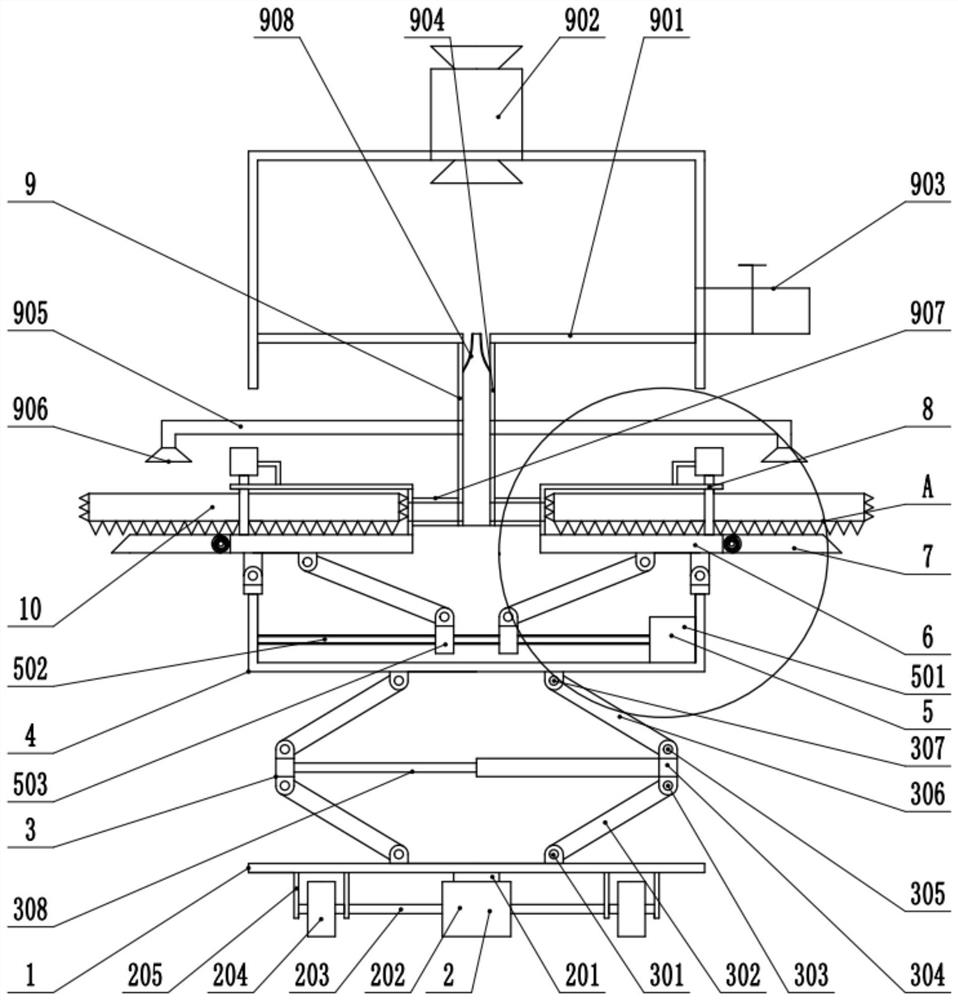

[0027] see Figure 1-3 , a chicken house dust removal device, comprising a base 1,

[0028] The bottom of the base 1 is fixedly connected to the moving mechanism 2;

[0029] The side of the base 1 away from the moving mechanism 2 is fixedly connected to the height adjustment mechanism 3;

[0030] The height adjustment mechanism 3 is fixedly connected to the box body 4;

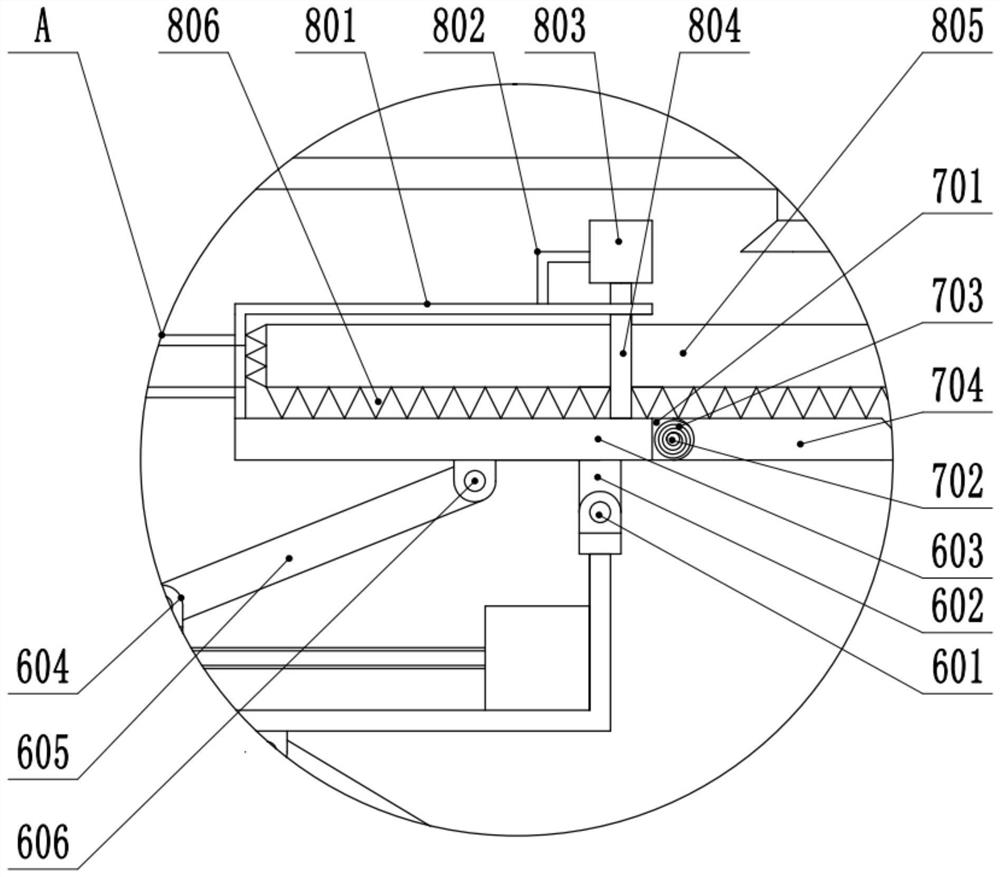

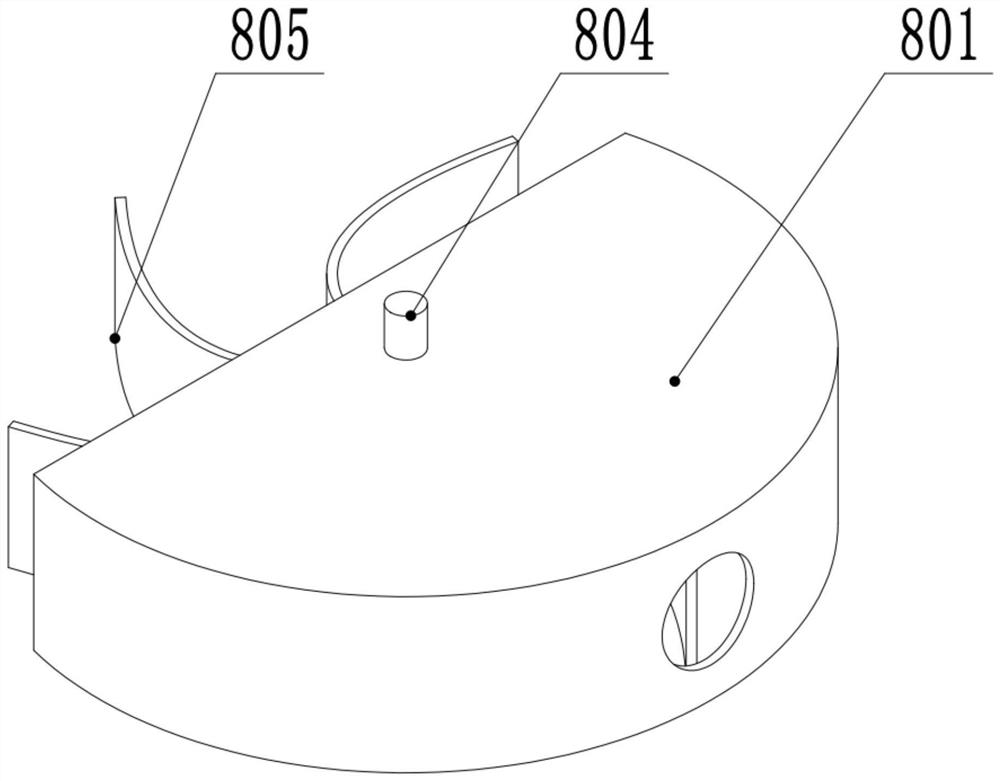

[0031] The box body 4 is fixedly connected to the cleaning assembly 10, and the cleaning assembly 10 includes an adjusting block mechanism 5, a rotating plate mechanism 6, a fitting plate mechanism 7, and a scraper mechanism 8. The adjusting block mechanism 5 is used to drive the rotating plate mechanism 6 to rotate, and the rotating plate mechanism Mechanism 6 is used to drive the laminating plate mechanism 7 and the scraper mechanism 8 to rotate, the laminating plate mechanism 7 is used to ensure bottom support collection, and the scraper mechanism 8 is used to realize the function of scraping and cleaning...

Embodiment 2

[0046] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, except that: the height adjustment mechanism 3 includes a first rotating seat 301 fixed on the base 1, and the first rotating seat 301 is rotatably connected to the first connecting rod 302, The first connecting rod 302 is rotatably connected to the second rotating seat 303, the second rotating seat 303 is fixedly connected to the height adjustment block 304, the height adjusting block 304 is fixedly connected to the third rotating seat 305, and the third rotating seat 305 is rotatably connected to the second connecting rod 306, The second connecting rod 306 is rotatably connected to the fourth rotating seat 307 , and the electric telescopic rod 308 is fixedly connected between the height adjustment blocks 304 .

[0047] Specifically, when the electric telescopic rod 308 is turned on, the distance between the height adjustment blocks 304 can be controlled, and the height of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com