Novel building template

A building formwork and a new type of technology, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of less turnover, long cost recovery period, difficult construction, etc., to prevent the corrosion of weak acid and strong alkali. , Conducive to mass production, simple and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

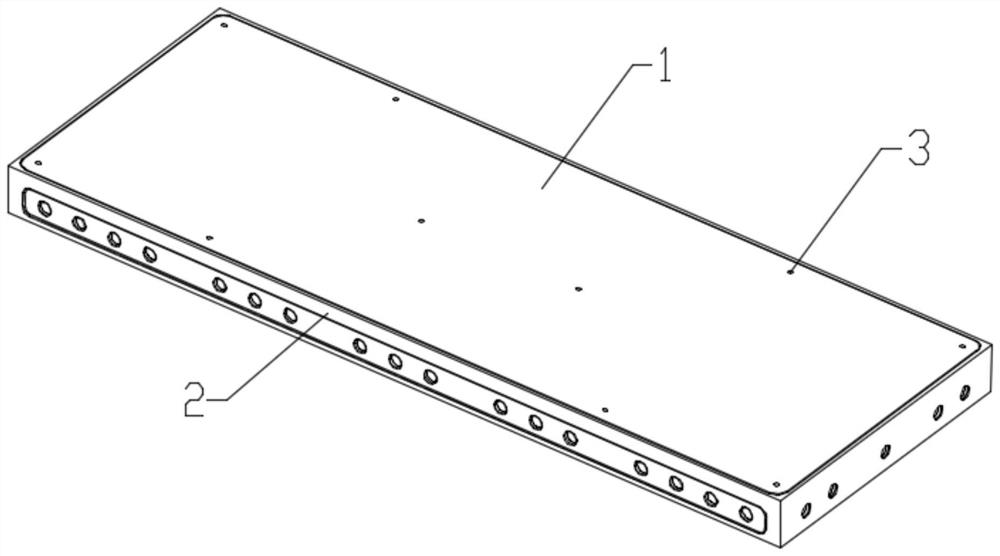

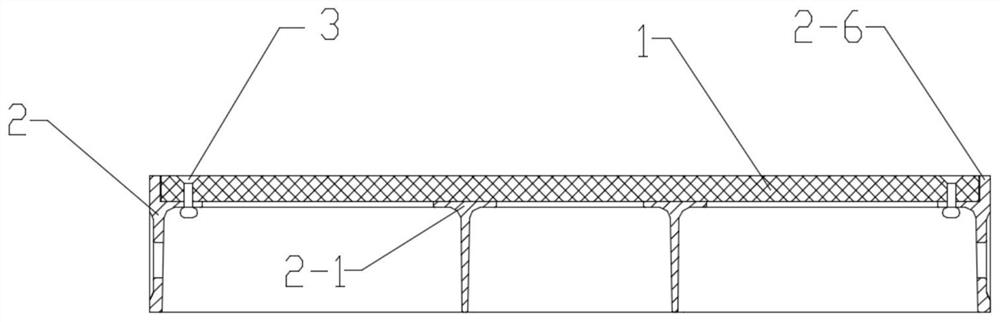

[0024] The invention provides a new type of building template, which includes a panel and an aluminum alloy frame. A panel is fixed on the upper side of the aluminum alloy frame. The panel is fixed on the aluminum alloy frame by rivets. T-shaped ribs A, the T-shaped ribs A are flush with the back of the aluminum alloy frame; several T-shaped ribs B are arranged horizontally inside the aluminum alloy frame, and the height of the T-shaped ribs B is lower than that of the aluminum alloy frame frame back. Two integrally formed handles are arranged between the T-shaped ribs A inside the aluminum alloy frame. The main surface of the aluminum alloy frame is surrounded by a circle of fences whose height is equal to the thickness of the panel. The four corners inside the fence are provided with four rounded corners. A support surface is installed inside the aluminum alloy frame, and the support surface Placed on the fillet. The lower side of the aluminum alloy frame is a frame, and t...

Embodiment 2

[0031] A kind of building formwork of the present invention, such as Figure 1-4 As shown, its assembly process is as follows:

[0032] The first step is to connect the panel 1 to the aluminum alloy frame 2, so that the panel 1 is placed on the support surface 2-7 of the aluminum alloy frame 2, and then use screws or rivets to pass through the panel 1 and the aluminum alloy frame 2 in order to complete the fixation.

[0033] In the present invention, a plurality of building templates are connected, and the connection method is to put two building templates together, make the aluminum alloy frame 2 close together, make the pin holes 2-3 on the aluminum alloy frame 2 correspond, and then use the pin Pass through the pin holes 2-3 of the two building formwork aluminum alloy frames 2 for fixing.

Embodiment 3

[0035] A kind of building formwork of the present invention, such as Figure 1-4 As shown, its assembly process is as follows:

[0036] The first step is to connect the panel 1 to the aluminum alloy frame 2, so that the panel 1 is placed on the support surface 2-7 of the aluminum alloy frame 2, and then use screws or rivets to pass through the panel 1 and the aluminum alloy frame 2 in order to complete the fixation.

[0037] The present invention does not connect multiple building templates, and the pin holes 2-3 on the aluminum alloy frame 2 are equipped with baffles correspondingly, so that the building mold can be used normally when it is used alone, and the mud will not be left outside, ensuring the pouring accuracy Work properly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com