High-deep-drawability ultra-pure ferritic stainless steel and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the field of metal processing, can solve problems such as easy cracking, low deep drawing performance, complex processing technology, etc., to achieve the effect of reducing the processing defect rate and improving deep drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A kind of high deep drawability ultra-pure ferritic stainless steel of the present invention, the chemical composition of stainless steel strip is counted as: C≤0.025%, Si≤1.00%, Mn≤1.00%, P≤0.040%, S ≤0.030%, Cr: 17.0%~19.0%, Mo: 0.75%~1.50%, N≤0.025%, 8(C+N)≤Ti+Nb≤0.80%, the balance is Fe and unavoidable impurity elements.

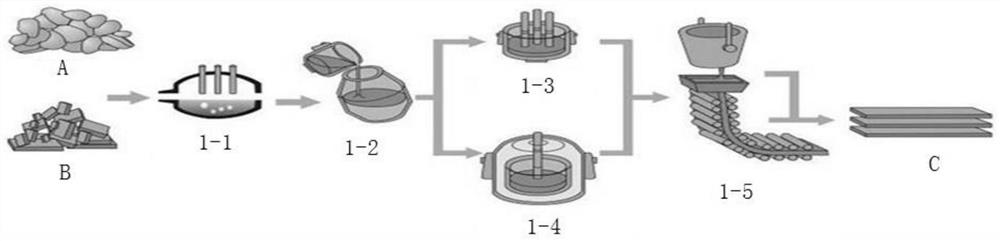

[0029] A kind of manufacturing method of high deep drawability ultra-pure ferritic stainless steel of the present invention, comprises the following steps:

[0030] 1) After smelting, continuous casting and hot rolling, black steel coils are obtained;

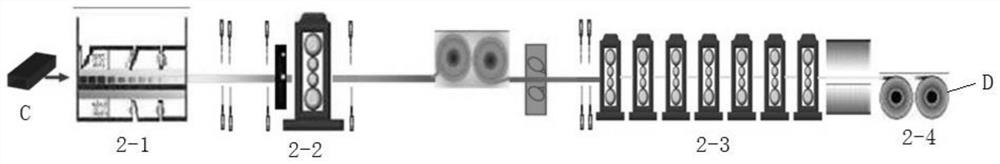

[0031] 2) The steel coils with black skins are subjected to solid solution, sand blasting and pickling to obtain No.1 surface steel coils;

[0032] 3) The No.1 surface steel coil is rolled back and forth for multiple passes, and the cold deformation reduction is controlled to be above 73%, to obtain a hard steel coil;

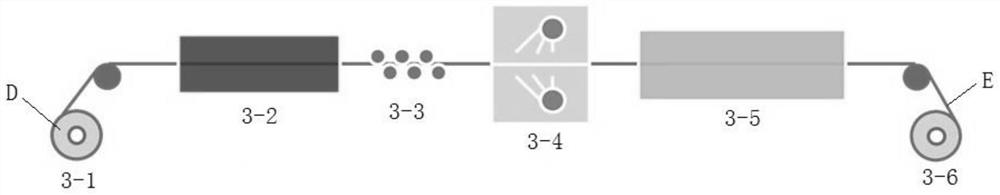

[0033] 4) The hard plate steel coil is subjected to solid solution, electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com